معالجة حفر الياقوت

Sapphire Drilling Processing – Precision micro-drilling for advanced medical and industrial use

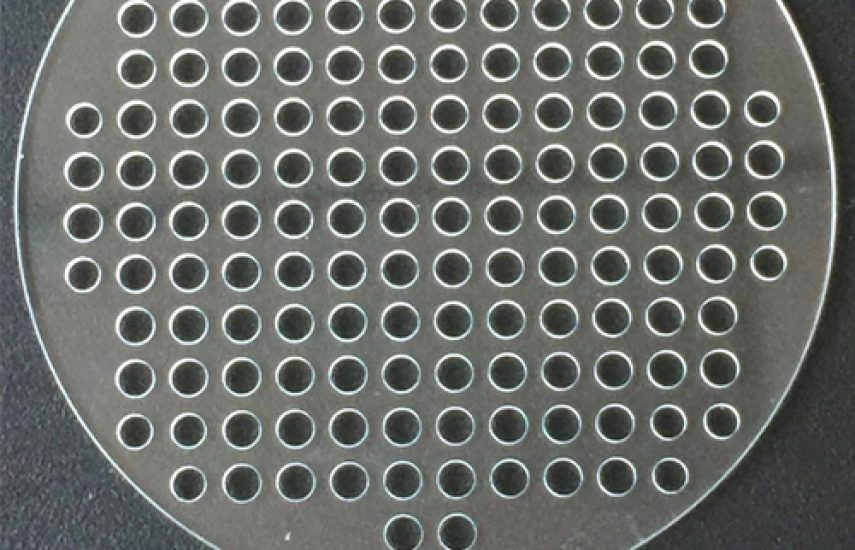

Sapphire Drilling Processing is a high-precision manufacturing technology designed for creating micro-holes and intricate features in sapphire, one of the hardest and most durable materials. Utilizing femtosecond laser processing, this technique ensures clean edges, burr-free finishes, and exceptional dimensional accuracy. Sapphire’s unique properties such as extreme hardness, biocompatibility, and optical clarity make it an ideal choice for critical applications in medical devices, optics, semiconductors, and high-performance electronics.

الميزات الرئيسية:

- Ultra-precise femtosecond laser drilling with tolerances ≤±5 μm

- Smooth, burr-free holes with diameters from a few microns to sub-millimeter scale

- High resistance to wear, heat, and chemical corrosion

- Biocompatible and safe for long-term use in medical implants

- Suitable for transparent and high-strength components requiring optical clarity

Certification and Standards:

Complies with ISO 13485 and ISO 10993 for medical-grade manufacturing and meets international quality and safety regulations.

Primary Material – Sapphire. Exceptional scratch resistance, high thermal stability, and transparency for optical and medical applications.

Compatible Materials:

- الألومينا

- زركونيا

- Silicon nitride

- other high-hardness ceramics

- Medical devices: surgical tools, implants, and diagnostic optics

- Semiconductor industry: sapphire substrates and packaging components

- Telecommunications: optical windows and lenses

- Industrial use: high-durability wear-resistant components

- Material: Sapphire (single-crystal Al2O3)

- Drilling accuracy: ≤±5 μm

- Hole diameter range: 5 μm – 1 mm

- Surface finish: Ra < 0.2 μm

- Processing method: femtosecond laser drilling