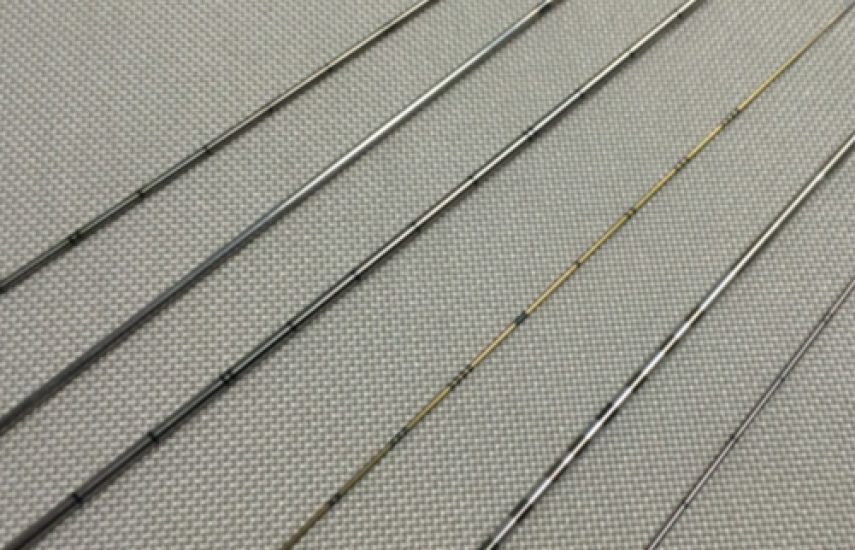

جميع أنواع علامات الإبر والأنابيب

All Kinds of Needle and Tube Marking – versatile, high-precision laser marking for medical components

All Kinds of Needle and Tube Marking is a specialized laser process developed to provide durable, biocompatible, and high-contrast markings on medical needles and tubes. This advanced technique eliminates the need for inks, coatings, or consumables, ensuring hygienic and permanent identification. The process is suitable for a wide variety of medical-grade metals, offering flexibility in marking codes, logos, scales, or other identifiers while preserving material integrity and ensuring resistance to sterilization and cleaning cycles.

Key features:

- Non-contact laser process: clean, precise markings without contamination or material damage

- Permanent identification: resistant to sterilization, abrasion, and chemicals

- High-contrast readability: clear markings for quick recognition and traceability

- Material versatility: compatible with stainless steel, Ni-Ti, platinum-iridium, tantalum, cobalt-base alloys, aluminum, and copper

- Customizable content: logos, serial numbers, graduation scales, or barcodes possible

Certification and Standards:

Produced under ISO9001 and ISO13485 certified systems; the process complies with international medical device standards, ensuring biocompatibility, traceability, and long-term durability.

Stainless Steel SUS304:

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- التوافق الحيوي: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

Platinum-Iridium:

Platinum-Iridium is a biocompatible, corrosion-resistant alloy with exceptional durability and conductivity. Ideal for precision laser welding, it ensures strong, smooth joints for critical medical components like stone basket heads.

Aluminum alloy:

Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

Titanium alloys:

Titanium Alloys are medical-grade materials prized for their high strength-to-weight ratio, excellent corrosion resistance, and superior biocompatibility. With tensile strength ranging from 900–1200 MPa and good ductility, they provide durability and flexibility for demanding medical applications. Their bio-inert properties make them ideal for implants and instruments requiring direct tissue contact. Laser-machined surfaces ensure smooth, burr-free finishes, minimizing tissue irritation in sensitive procedures.

Copper (Cu):

A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

Plastic:

Plastic is widely used in the manufacturing of medical devices due to its lightweight properties, cost-effectiveness, and design flexibility. Medical-grade plastics are biocompatible, resistant to corrosion and chemicals, and can withstand sterilization processes, making them safe for direct contact with patients. Their versatility allows the production of complex shapes and components with consistent quality, supporting innovation in surgical instruments, diagnostic equipment, and disposable medical products.

- Medical needles requiring permanent and biocompatible markings

- Tubes for surgical instruments and diagnostic devices

- Implantable components with traceable identification needs

- Marking type: high-contrast laser engraving

- Durability: resistant to sterilization, abrasion, and cleaning cycles

- Surface integrity: no coatings, no damage, no deformation

- Customization: logos, codes, graduations, barcodes

- Compliance: ISO9001, ISO13485 medical device standards