قطع وتشكيل ركيزة الألومنيوم 02

Aluminum Substrate Cutting and Forming 02 – Precision Laser Processing for Advanced Electronics

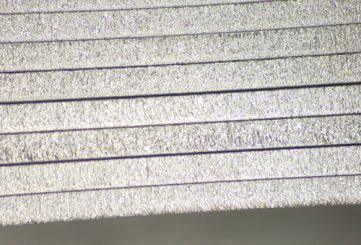

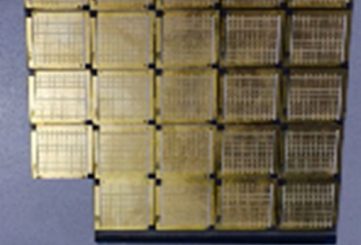

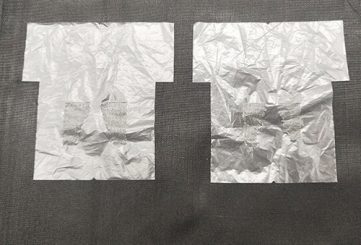

Aluminum Substrate Cutting and Forming 02 is a high-precision laser machining process engineered to produce intricate components from aluminum substrates for medical and electronic applications. Leveraging advanced fiber laser technology with nitrogen assist, this process ensures clean, burr-free cuts and precise forming with minimal thermal distortion. Crafted from high-quality aluminum, renowned for its superior electrical and thermal conductivity, corrosion resistance, and lightweight properties, the resulting components are ideal for medical sensors, electronic circuits, and high-density interconnects. The laser-cut design delivers smooth edges and complex patterns, optimizing performance in demanding environments. Tailored for high-precision applications, this process meets the exacting standards of modern healthcare and electronics manufacturing.

الميزات الرئيسية:

- Ultra-Precise Cutting: Seam width of 15–30 µm with machining accuracy of ≤±10 µm for intricate circuit designs.

- Burr-Free Edges: Smooth surfaces ensure reliable performance and safe integration in sensitive applications.

- High Conductivity: Aluminum substrates provide excellent electrical and thermal conductivity for high-performance electronics.

- Minimal Thermal Impact: Fiber laser with nitrogen assist minimizes oxidation and thermal distortion for enhanced material integrity.

- تنوع المواد: Compatible with aluminum foils and aluminum-based laminates for diverse applications.

- Automated Production: Direct-drive XY motion platform ensures high efficiency and consistent quality.

Certification and Standards:

The Aluminum Substrate Cutting and Forming 02 process is certified under ISO 9001, ensuring consistent quality management across all production stages. It also complies with IATF 16949, guaranteeing exceptional quality control and traceability for critical applications in electronics and medical industries.

Aluminum Substrate:

- Excellent Thermal Conductivity: Efficiently dissipates heat, ideal for high-power electronics like LED lighting and medical imaging devices.

- Lightweight: Reduces overall device weight, enhancing portability for applications in wearables and compact electronics.

- Cost-Effective: Offers a balance of performance and affordability, suitable for large-scale electronics manufacturing.

- Corrosion Resistance: Resists environmental degradation, ensuring durability in harsh conditions.

- Mechanical Strength: Provides robust support for circuit components, maintaining structural integrity under stress.

- Recyclability: Environmentally friendly, supporting sustainable manufacturing practices.

Copper Substrate:

- Superior Electrical Conductivity: Ensures efficient signal transmission, critical for high-frequency 5G antennas and power electronics.

- High Thermal Conductivity: Effectively manages heat dissipation, ideal for high-performance PCBs and medical devices.

- Ductility: Allows precise forming and shaping, enabling intricate designs for compact electronic assemblies.

- Durability: Resists wear and tear, providing long-term reliability in demanding applications.

- Solderability: Facilitates strong, reliable connections in circuit assembly, enhancing manufacturing efficiency.

- High-Density Interconnect Support: Enables complex, high-density circuit designs for advanced electronics.

Ceramic Substrate:

- Exceptional Thermal Stability: Withstands extreme temperatures, ideal for high-power and high-frequency electronics like RF modules.

- Superior Electrical Insulation: Prevents unwanted conductivity, ensuring reliable performance in sensitive medical and telecom devices.

- High Mechanical Strength: Maintains structural integrity under stress, supporting precision manufacturing of complex designs.

- Chemical Inertness: Resists corrosion from chemicals and environmental factors, ensuring long-term reliability.

- Low Dielectric Loss: Enhances signal integrity, making it perfect for high-frequency applications like 5G and radar systems.

- Biocompatibility: Suitable for medical implants and diagnostic equipment due to its non-reactive properties.

- Medical Sensors: Produces precision components for wearable and diagnostic medical devices.

- Electronic Circuits: Creates intricate layouts for consumer electronics and high-density interconnects.

- Diagnostic Equipment: Supports high-precision substrates for imaging and laboratory devices.

- Industrial Electronics: Used in robust components for control systems and power electronics.

- Medical Device Manufacturing: Incorporated in the production of advanced electronic substrates.

- Material: Aluminum Foil, Aluminum-based Laminates

- Thickness: 0.05–0.5 mm

- Cutting Seam Width: 15–30 µm

- Machining Accuracy: ≤±10 µm

- Surface Roughness: Ra <0.2 µm

- Manufacturing Process: Fiber laser cutting with nitrogen assist and automated feeding

- Operating Temperature: -20°C to 150°C, suitable for high-performance applications

- Degradation: Non-degradable, designed for long-term stability