نقش أعمى 9.5 مم لأنبوب من الفولاذ المقاوم للصدأ

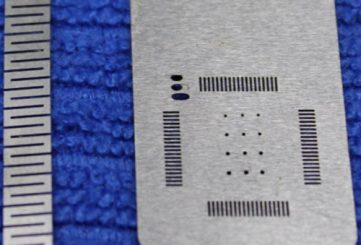

9.5mm Blind Engraving of Stainless Steel Tube – Precision Process for Medical and Industrial Tubing

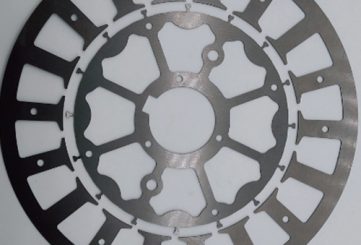

The 9.5mm Blind Engraving of Stainless Steel Tube is a high-precision laser engraving process designed to create intricate, non-penetrating patterns on stainless steel tubing for medical and industrial applications. Utilizing advanced five-axis laser technology, this process ensures exceptional accuracy, durability, and a burr-free finish. Crafted from high-quality stainless steel with a 9.5 mm diameter, the engraved tubes offer superior corrosion resistance and strength, ideal for surgical instruments, diagnostic devices, and precision industrial components. The blind engraving technique delivers smooth surfaces and detailed designs without compromising tube integrity, optimizing performance in demanding environments. Tailored for high-precision applications, this process meets the rigorous standards of modern healthcare and engineering.

الميزات الرئيسية:

- Ultra-Precise Engraving: Engraving accuracy of ≤±10 µm for intricate, non-penetrating designs.

- Burr-Free Finish: Smooth surfaces ensure safe use and minimal tissue trauma in medical applications.

- High Strength: Stainless steel provides robust tensile strength for reliable performance.

- مقاومة التآكل: Engineered for durability in harsh medical and industrial environments.

- Non-Penetrating Design: Blind engraving preserves tube structural integrity for enhanced functionality.

- Automated Production: Continuous feeding system ensures high efficiency and consistent quality.

Certification and Standards:

Certified under ISO 9001 and ISO 13485 for quality management. Compliant with CE and FDA regulations for medical device safety and efficacy.

316L Stainless Steel:

316L Stainless Steel is a medical-grade austenitic chromium-nickel alloy renowned for its excellent corrosion resistance and biocompatibility. With a tensile strength of approximately 485–550 MPa and elongation up to 40%, it offers durability and flexibility without brittleness. Its low carbon content enhances weldability and resistance to intergranular corrosion, making it ideal for medical implants and instruments. Laser-machined for smooth, burr-free surfaces, it minimizes tissue irritation in sensitive applications. The 316L Stainless Steel gives:

- Corrosion Resistance: Withstands physiological and environmental exposure for long-term durability.

- Structural Integrity: Ideal for medical and industrial applications requiring robust yet flexible materials.

- Precision Compatibility: Supports advanced laser micromachining for detailed designs.

- Medical Devices: Produces engraved tubing for surgical instruments and diagnostic equipment.

- Industrial Systems: Creates precision components for fluid and gas handling systems.

- Surgical Instruments: Supports intricate designs for minimally invasive procedures.

- Diagnostic Equipment: Used in high-precision tubing for imaging and laboratory devices.

- Medical Device Manufacturing: Incorporated in the production of advanced tubing components.

- Material: Stainless Steel (e.g., SUS304, SUS316L)

- Diameter: 9.5 mm

- Engraving Accuracy: ≤±10 µm

- Surface Roughness: Ra <0.2 µm

- Manufacturing Process: Five-axis laser engraving with automated feeding

- Operating Temperature: -20°C to 300°C, suitable for sterilization

- Degradation: Non-degradable, designed for long-term stability