قطع وتشكيل شريط زخرفي من الفولاذ المقاوم للصدأ بوزن 0.2 مم وطول 1400 مم وعرض 600 مم

WT0.2mm L1400mm W600mm Stainless Steel Decorative Strip Cutting and Forming – Precision Process for Aesthetic and Functional Components

The WT0.2mm L1400mm W600mm Stainless Steel Decorative Strip Cutting and Forming is a high-precision laser machining process designed to produce thin, durable decorative strips for medical and industrial applications. Utilizing advanced five-axis laser cutting technology, this process ensures exceptional accuracy, durability, and a burr-free finish. Crafted from high-quality stainless steel with a thickness of 0.2 mm, the resulting strips offer superior corrosion resistance and strength, ideal for aesthetic components in medical devices, diagnostic equipment, and industrial systems. The laser-cut design delivers smooth edges and intricate patterns, ensuring both functionality and visual appeal in demanding environments. Tailored for high-precision applications, this process meets the rigorous standards of modern healthcare and engineering.

الميزات الرئيسية:

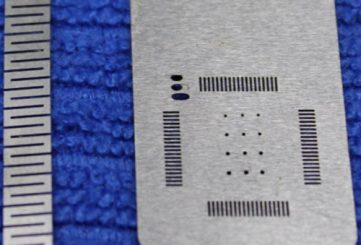

- Ultra-Precise Cutting: Seam width of 15–30 µm with machining accuracy of ≤±10 µm for intricate decorative designs.

- Burr-Free Edges: Smooth surfaces ensure safe use and seamless integration in sensitive applications.

- Ultra-Thin Profile: 0.2 mm thickness enables lightweight and precise strip production.

- High Strength: Stainless steel provides robust tensile strength for reliable performance.

- مقاومة التآكل: Engineered for durability in harsh medical and industrial environments.

- Automated Production: Continuous feeding system ensures high efficiency and consistent quality.

Certification and Standards:

Certified under ISO 9001 and ISO 13485 for quality management. Compliant with CE and FDA regulations for medical device safety and efficacy.

Precision Stainless Steel:

- Exceptional corrosion resistance ensures durability in harsh medical and industrial environments.

- High tensile strength (500–1000 MPa) provides robust structural integrity.

- Biocompatibility (ISO 10993) makes it ideal for medical implants and tools.

- Smooth surface finish (Ra <0.2 µm) minimizes tissue trauma and enhances performance.

Hard Alloy Steel:

- Superior hardness (up to 60–65 HRC) ensures excellent wear resistance.

- High strength and toughness support heavy-duty applications in surgical and industrial tools.

- Corrosion resistance extends lifespan in demanding environments.

- Precision machinability allows for intricate designs with tight tolerances.

Other Surface-Treated Materials:

- Includes coated or anodized metals like titanium, aluminum, and stainless steel with enhanced surface properties.

- Surface treatments such as passivation, nitriding, or PVD coatings improve wear resistance, biocompatibility, and corrosion protection.

- Medical Devices: Produces decorative and functional strips for surgical tools and diagnostic equipment.

- Industrial Systems: Creates aesthetic components for electronics and automation systems.

- Diagnostic Equipment: Supports precise decorative elements in imaging and laboratory devices.

- Architectural Applications: Used in high-precision decorative panels for medical and industrial facilities.

- Medical Device Manufacturing: Incorporated in the production of advanced aesthetic and functional components.

- Material: Stainless Steel (e.g., SUS304, SUS316L)

- Thickness: 0.2 mm

- Dimensions: Length 1400 mm, Width 600 mm

- Cutting Seam Width: 15–30 µm

- Machining Accuracy: ≤±10 µm

- Surface Roughness: Ra <0.2 µm

- Manufacturing Process: Five-axis laser cutting with automated feeding

- Operating Temperature: -20°C to 300°C, suitable for sterilization

- Degradation: Non-degradable, designed for long-term stability