منتجات عالية الدقة

0 عناصرCustom Manufacturing of High-Precision Components According to Customer Specifications

We offer precision manufacturing of high-accuracy components for medical and industrial applications, fully based on customer requirements. All parts are produced according to provided drawings, CAD models, or detailed technical specifications.

Our flexible manufacturing process supports a wide range of custom geometries, critical tolerances, materials, and surface finishes. We work closely with our clients to ensure their specific application needs are met at every stage — from prototyping to series production.

Read more about Application and Key Features…

Application:

High-precision components are essential in a variety of medical and engineering fields that demand exact tolerances and repeatable performance. Typical applications include:

- Micro-mechanical parts for medical devices

- Components for surgical tools and diagnostic equipment

- Precision parts for catheter systems

- Custom inserts, holders, and structural elements for lab setups

- R&D components for clinical testing and prototyping

To discuss your project or request a quote, please contact us with your drawings or technical documentation.

Key capabilities include:

- Manufacturing based on customer drawings and 3D CAD models

- Tight tolerances and high repeatability

- Support for a wide range of metals and polymers

- Micro-machining, laser cutting, drilling, and marking

- Prototyping and small to medium batch production

- Post-processing and surface finishing options upon request

Each order is treated as a custom project, ensuring compliance with your technical requirements and quality standards. Our facility is equipped for contract manufacturing and OEM supply with full documentation and traceability.

- قطع الدعامة

- عظام الثعبان

- أنبوب تحت الجلد (أنبوب تحت الجلد)

- الإبر

- الأدوات الجراحية

- الأجهزة الطبية

- قطع وتشكيل الفولاذ المقاوم للصدأ

- ركائز تصنيع الإلكترونيات

- الأجهزة الصلبة والهشة

- الأجهزة غير المعدنية

- الوسم واللحام

-

الدوارات والستاتورات الكهربائية المصنوعة من الفولاذ

الدوارات والثابتات هي مكونات أساسية للأجهزة الكهرومغناطيسية، يتم تجميعها من أكوام من الصفائح الفولاذية الكهربائية المقطوعة بالليزر (سمكها 0.1-1 مم)، وعادة ما تكون غير موجهة للحصول على خصائص مغناطيسية موحدة -

قطع وتشكيل الجلود

قطع وتشكيل الجلود هي خدمة تصنيع دقيقة مصممة لإنشاء مكونات جلدية عالية الجودة بتصميمات معقدة وأبعاد دقيقة. -

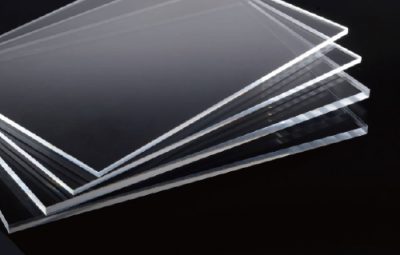

قطع وتشكيل الأكريليك

قطع وتشكيل الأكريليك هي خدمة تصنيع دقيقة مصممة لإنشاء مكونات عالية الجودة من مواد الأكريليك. -

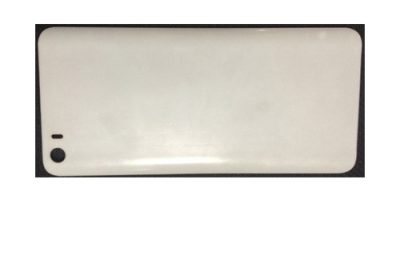

قطع وتثقيب وتشكيل غلاف الهاتف المحمول (الكمبيوتر الشخصي + الألياف الزجاجية)

تم تصميم خدمة قطع وتشكيل غلاف الهاتف المحمول (الكمبيوتر الشخصي + الألياف الزجاجية) لإنشاء مكونات دقيقة ومتينة لأغلفة الهواتف المحمولة. -

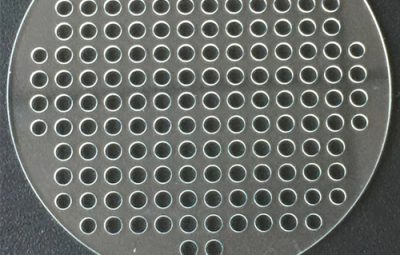

تبريد علب الكمبيوتر المحمول المصنوعة من مادة ABS وقطع الثقوب وتشكيلها

تم تصميم خدمة قطع وتشكيل فتحات تبريد علب ABS للكمبيوتر المحمول لإنشاء فتحات تبريد وأنماط تهوية دقيقة في علب البلاستيك ABS لأجهزة الكمبيوتر المحمولة والأجهزة الإلكترونية. -

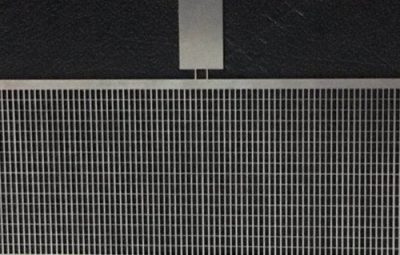

فتحات ألواح السيراميك

تعد عملية تشكيل الصفائح الخزفية عملية تصنيع دقيقة مصممة لإنشاء فتحات وأخاديد في الصفائح الخزفية. -

سيراميك أكسيد السيليكون وزن 0.2 مم للحفر

إن سيراميك أكسيد السيليكون WT0.2mm Drilling هو حل حفر دقيق مصمم لإنشاء ثقوب فائقة الدقة في المواد الصلبة والهشة. -

سيراميك الزركونيا وزن 0.7 مم

أداة الكتابة والنقش Zirconia Ceramics WT0.7mm هي أداة دقيقة مصممة للكتابة والنقش عالية الدقة على المواد الصلبة والهشة. -

معالجة حفر الياقوت

معالجة حفر الياقوت هي خدمة تصنيع عالية الدقة مصممة لإنشاء ثقوب وأنماط معقدة في مواد الياقوت. -

غطاء خلفي للهاتف المحمول مصنوع من السيراميك

يُعد غطاء الهاتف المحمول الخلفي المصنوع من السيراميك مكونًا عالي الدقة مصممًا للهواتف الذكية الحديثة، حيث يوفر مزيجًا مثاليًا من المتانة والجماليات والوظائف. -

قطع وتشكيل صفائح الفولاذ التنغستن

تعد عملية قطع وتشكيل صفائح الفولاذ التنغستن عملية دقيقة مصممة لإنشاء مكونات متينة وعالية القوة من الفولاذ التنغستن. -

صب الياقوت

Sapphire Molding هو مكون دقيق مصمم للاستخدام في الصناعات ذات التقنية العالية، وخاصة في التطبيقات التي تتطلب صلابة استثنائية، واستقرار حراري، ووضوح بصري. -

قوالب سيراميك نتريد الزركونيوم

قوالب السيراميك من نتريد الزركونيوم عبارة عن حل تصنيع دقيق بالليزر عالي الدقة مصمم لإنشاء قوالب معقدة ومتينة في مواد السيراميك من نتريد الزركونيوم. -

نتريد الزركونيوم WT0.2 مم - 0.12 مم لتشكيل الثقوب الدقيقة

تشكيل الثقوب الدقيقة باستخدام نتريد الزركونيوم WT0.2mm-0.12mm هو حل تصنيع دقيق بالليزر عالي الدقة مصمم لإنشاء ثقوب دقيقة معقدة ومتينة في مواد نتريد الزركونيوم. -

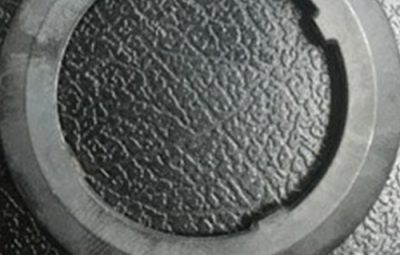

تشكيل حلقات ساعة MIM

تشكيل حلقات الساعات MIM هو حل تصنيع دقيق بالليزر عالي الدقة مصمم لإنشاء قطع معقدة ومتينة على حلقات الساعات المصنوعة من حقن المعادن (MIM). -

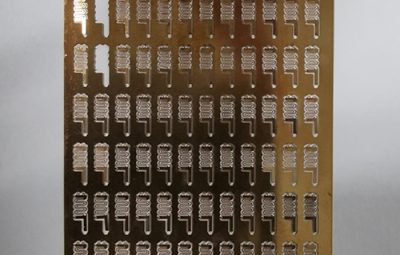

عملية تشكيل المسبار المطلي بالذهب

آلة القطع بالليزر فوق البنفسجية هي قطعة من المعدات المتخصصة للغاية والمصممة لتطبيقات التصنيع الدقيق بالليزر مثل تقسيم لوحة الدوائر المطبوعة بالليزر -

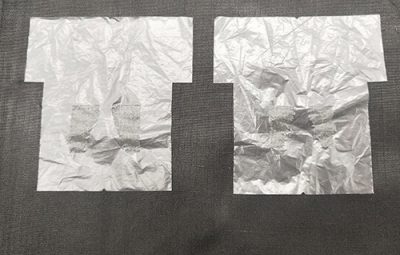

قص الأفلام

إن قطع الفيلم عبارة عن حل تصنيع دقيق بالليزر عالي الدقة مصمم لإنشاء قطع معقدة ودائمة على مواد الفيلم المختلفة. -

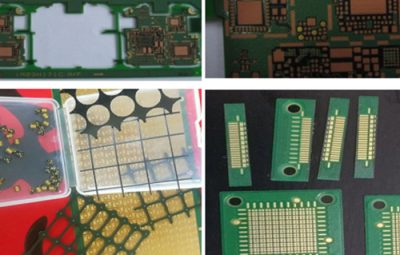

قطع وتشكيل لوحات الدوائر المطبوعة والألياف الزجاجية

إن قطع وتشكيل PCB والألياف الزجاجية هو حل تصنيع دقيق بالليزر عالي الدقة مصمم لإنشاء قطع معقدة ومتينة على PCB (لوحة الدوائر المطبوعة) ومواد الألياف الزجاجية.