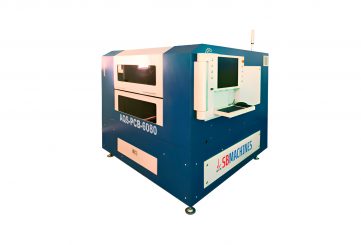

آلة القطع بالليزر ثاني أكسيد الكربون AQS-EE-5050 للمعدات الإلكترونية

AQS-EE-5050 Carbon Dioxide Laser Cutting Machine for Electronic Equipment – High-precision CO₂ solution for microstructure electronics

AQS-EE-5050 is a CO₂ laser micromachining platform specifically designed for high-precision electronic and microelectronic applications. This system features a refined gantry motion architecture and self-developed control algorithms to enable narrow-slit cutting, drilling, and etching of non-metallic substrates. Its compact footprint and user-oriented interface make it suitable for cleanroom integration and flexible production lines.

With selectable wavelengths and power settings, the machine achieves stable performance across various materials and thickness ranges. The design ensures low thermal impact, smooth edges, and minimal burr formation—ideal for delicate electronic components such as film-based parts, plastic structural elements, and insulating substrates.

Scope of application

This laser system is tailored to address demanding processes in electronics, medical device, and consumer device manufacturing. It supports microfabrication tasks on biofilms, polymeric substrates, 3C plastics, fabrics, and composite films used in precision equipment.

High precision etching

- Ultra-fine slit widths down to ≤ 80 µm

- Cutting accuracy of ≤ ±30 µm

- Smooth, burr-free cuts and high surface quality

- Efficient single-pass cutting through thin layers

- Compatibility with automatic handling and vision systems

High finishing

The AQS-EE-5050 excels in producing refined edges and surfaces even in thin or delicate films. By optimizing laser pulse parameters and scanning strategies, the system maintains excellent edge integrity, eliminating the need for extensive post-processing.

Benefits of high finishing:

- Minimal roughness and edge anomalies

- Superior consistency across batch processing

- Reduced cleaning or trimming steps downstream

- Enhanced yield for fine-feature electronics

Strong adaptability

The system supports a wide range of microfabrication techniques — including planar cutting, drilling, scribing, and slotting — on various non-metallic and composite substrates. Its modular motion and control architecture allow integration with automated feeders, vision alignment, and process feedback modules.

Because the platform is built with an open control philosophy, users can evolve its functionality over time—adapting to new materials, design rules, or production demands without complete reconfiguration.

Flexible design

This machine is engineered with modular hardware and software building blocks. Its architecture supports customization to match specific throughput, automation, and integration needs.

Key design flexibilities include:

- Modular configuration of hardware and control modules

- Customizable functions for production scheduling, monitoring, and feedback

- Ergonomic and compact structure suitable for process cell integration

- Support for open software interfaces and future expansions

Technical certification

The AQS-EE-5050 is manufactured under certified quality systems, including ISO 9001 and IATF 16949, ensuring traceability, consistency, and compliance with standards in regulated industries.

Sample Display

Processing Materials:

- Biological tissue films

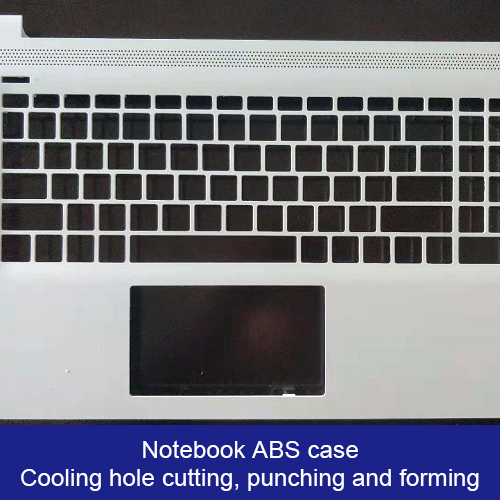

Delicate biofilms requiring clean, precise cutting for medical and research applications. - 3C plastic structural parts

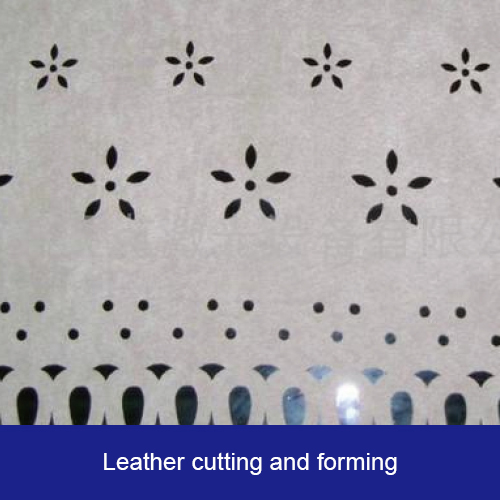

High-precision processing of plastics used in computers, communications, and consumer electronics. - Rubber

Accurate cutting and shaping of flexible, elastic materials with smooth edges. - Epoxy resin

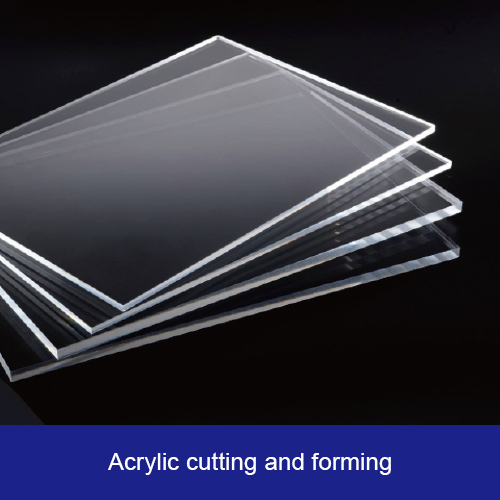

Stable processing of durable insulating components widely used in electronics. - Acrylic

Clear, polished edges in transparent plastic parts for displays and housings. - Wool

Non-contact cutting of natural fibers with minimal thermal damage. - Wood and bamboo products

Fine engraving and cutting for decorative, electronic, or structural uses. - Paper

High-speed, burr-free cutting of thin substrates for packaging, labels, and insulation layers.

Laser Specifications:

- CO2 laser

- Wavelength options: 9.3μm, 10.3μm, 10.6μm

- Power options: 80W, 120W, 200W, 250W, 300W

- Material wall thickness: 0~2±0.05mm

Scope of Use:

- Laser micromachining for precision medical and electronic equipment

- Processing biofilms, 3C plastic structural parts, and fabrics for high-precision applications

Processing Capabilities:

- High precision etching with small slit width: ≤80μm

- Cutting precision: ≤±30μm

- Smooth cuts without burrs

- Single-layer wall thickness processed in one pass

Industries Served:

- Medical device manufacturing

- Electronics production

- Precision engineering for structural components

Performance and Efficiency

Maximum Operating Speeds:

- X, Y1, Y2 Axes: 500mm/s

- Z Axis: 30mm/s

Positioning Accuracy:

- ±10μm (X, Y1, Y2, Z)

Repeatability:

- ±4μm (X, Y1, Y2)

- ±5μm (Z)

Advanced Features

- Self-developed servo and direct-drive gantry precision motion platform

- Optional machine vision system for precision targeting

- Dust removal duct system for a clean processing environment

Certified Quality

- ISO9001

- IATF16949

Design Excellence

- Ergonomic and compact design for ease of use

- Flexible hardware and software configuration for customized solutions

- Self-developed 2D, 2.5D, and 3D CAM software systems with a user-friendly interface