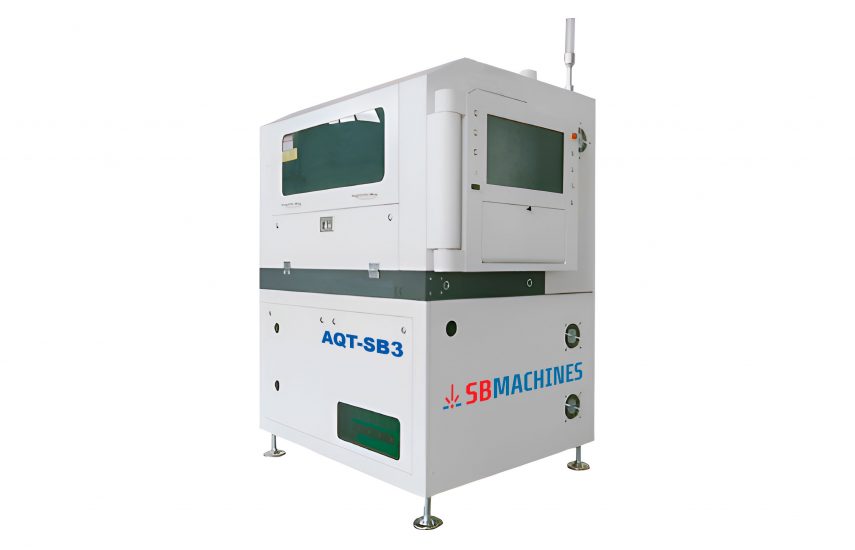

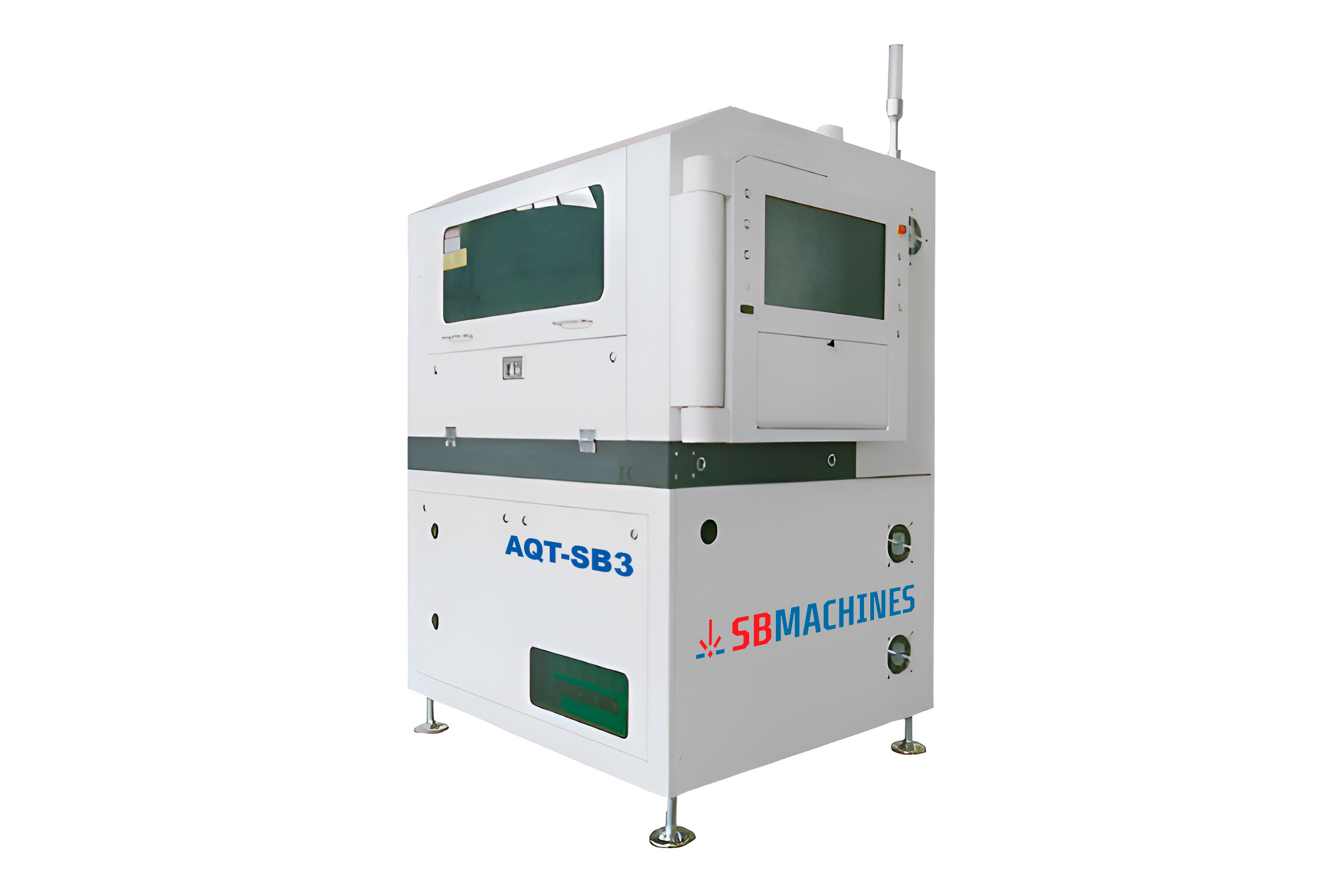

آلة القطع بالليزر AQT-SB3 لقسم الانحناء بالمنظار

آلة القطع بالليزر AQT-SB3 لقسم الانحناء بالمنظار

The AQT-SB3 is a precision laser cutting machine designed specifically for the bending sections of endoscopes. It features ultra-fine cutting seam widths and high machining accuracy, making it ideal for complex joints and tight geometries where smooth, burr-free cuts are essential. The machine supports both cutting and drilling operations on thin-walled tubes and provides continuous automatic feeding for efficient workflows.

Its robust build, versatile material compatibility (including stainless steels, Ni-Ti, L605 and other alloys), and support for multiple clamping systems allow the AQT-SB3 to deliver consistent high-quality results for medical, industrial, and electronic endoscopes.

Scope of application

Used widely in medical and industrial endoscope manufacturing, the AQT-SB3 is ideally suited for processing bending sections in devices like urinary, gastrointestinal, electronic, and industrial endoscopes. It also handles intricate “snake bone” structures with precision. Its capability includes fine cutting, drilling, slotting, and centripetal opening features for equal-diameter tubes.

Advantages:

- Very fine cutting seam width (15–30 µm) with high processing efficiency.

- High machining accuracy (≤ ±10 µm) ensures reliable tolerances.

- Versatile machining modes: dry cutting, wet cutting, drilling, grooving.

- Supports various alloys such as 304, 316L, Ni-Ti, L605

High finishing

The AQT-SB3 delivers superior finish quality for bending sections. The seam widths are narrow (15–30 µm), and cuts are smooth with minimal burrs. The combination of fine beam control and optimized laser parameters ensures that the bent segments maintain their geometry and surface integrity through stringent processes.

- Seam width: 15–30 µm

- Burr-free smooth incisions

- High consistency in precision machining

Strong adaptability

The machine is designed to adapt to diverse production needs, supporting dry and wet cutting modes, drilling, and slotting operations. It works with equal-diameter centripetal openings and thin-walled tubes, using different clamping systems such as D-type collets, ER series collets, and three-jaw chucks.

Adaptive compensation ensures precision when machining bent or semi-finished tubes. The system also integrates with 2D, 2.5D, and 3D CAM software for flexible programming and production management.

Flexible design

The AQT-SB3 combines ergonomic design with intelligent features. Its clear and compact layout simplifies operation, while optional machine vision enables real-time monitoring. Flexible software and hardware configuration allows customization to specific production requirements.

- Ergonomic and concise design

- Optional vision system for online monitoring

- Configurable features for customized applications

Technical certification

The AQT-SB3 complies with ISO 9001 and ISO 13485 certifications, ensuring high manufacturing quality and reliability for medical device production.

Sample display

Processing Materials:

- 304 Stainless Steel

- التوافق الحيوي: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

- الفولاذ المقاوم للصدأ 316L

- سبائك النيكل والتيتانيوم

- L605 and other alloys

316L Stainless Steel is a medical-grade austenitic chromium-nickel alloy renowned for its excellent corrosion resistance and biocompatibility. With a tensile strength of approximately 485–550 MPa and elongation up to 40%, it offers durability and flexibility without brittleness. Its low carbon content enhances weldability and resistance to intergranular corrosion, making it ideal for medical implants and instruments. Laser-machined for smooth, burr-free surfaces, it minimizes tissue irritation in sensitive applications.

النيتينول (NiTi)، وهو سبيكة من النيكل والتيتانيوم، مشهور بمرونته الفائقة وذاكرته الشكلية، مما يجعله رائدًا في التطبيقات الطبية. بفضل قوة شد تصل إلى 1200 ميجا باسكال ومعامل مرونة يتراوح بين 40 و75 جيجا باسكال، يتفوق النيتينول في البيئات الصعبة.

Cobalt-Chromium Alloys (L605) are medical-grade materials valued for their exceptional strength, corrosion resistance, and biocompatibility. With tensile strength ranging from 800–1500 MPa and hardness of 300–550 HV, they ensure durability in demanding medical applications. Ideal for implants and surgical tools, they support direct tissue contact with minimal reaction. Laser-machined surfaces provide smooth, burr-free finishes, enhancing performance in sensitive procedures.

Sıkıştırma sistemleri:

- Precision D-Type Collets

- ER Series Collets

- Three-Jaw Chucks

Laser Type and Specifications:

- Fiber-Optic Laser

- Wavelength: 1030~1070nm±10nm

- Power Options: 100W, 200W, 300W, 500W

Scope of Use

- Endoscopes:

- Medical Endoscopes

- Industrial Endoscopes

- Electronic Endoscopes

- Snake Bone Laser Micromachining

Processing Capabilities

- Laser Cutting, Drilling, and Grooving

- Centripetal Opening Features for Equal Diameter Tubes

- Seam Width: 20~30 μm

- High Accuracy: ≤ ±10 μm

Industries Served

- Medical and Industrial Endoscopy Equipment Manufacturing

Performance and Efficiency

- Maximum Operating Speeds:

- X-Axis: 300 mm/s

- Z-Axis: 50 mm/s

- θ-Axis: 600 rpm

Versatility

- Machining Wall Thickness: 0~1.0 ± 0.02 mm

- Pipe Processing Range:

- Φ0.3~Φ7.5 mm

- Φ1.0~Φ16.0 ± 0.02 mm

- Tube Blank Length: <2.5 m (customizable for infinitely long pipe feeding)

Flexibility and Customization

- Continuous Automatic Feeding Processing

- Compatible File Formats: DXF, DWG

- Supports 2D, 2.5D, and 3D CAM Software for Precision Micromachining

Certified Quality

- ISO9001, ISO13485 Certifications

User-Friendly Design

- Optional Machine Vision System for Real-Time Monitoring

- Ergonomic Design with Intuitive Interface for Easy Operation

- Adaptive Shape Tolerance Changes for Thin-Walled Tubes