مشبك منظار داخلي SUS304

SUS304 Endoscope Clip – Precision Clips for Endoscopic Procedures

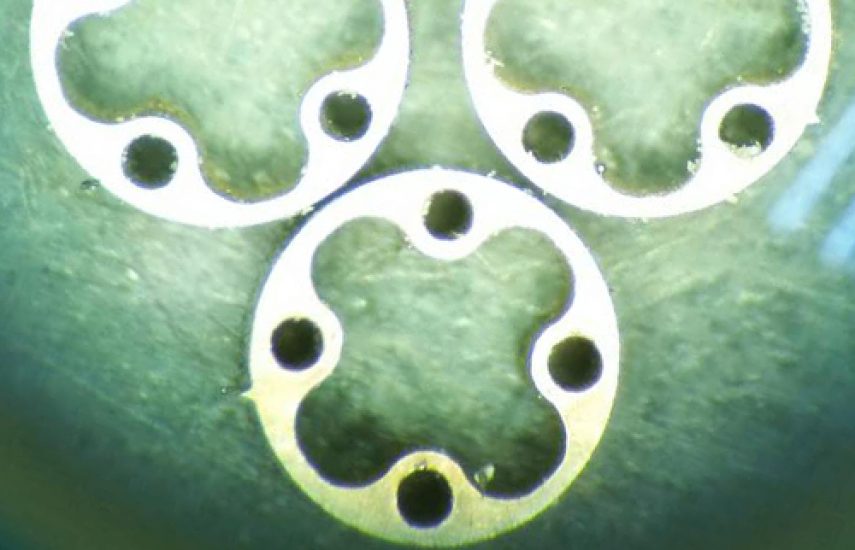

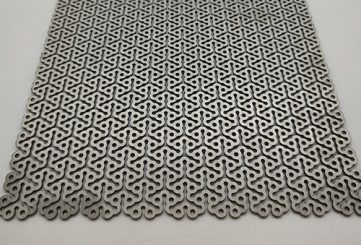

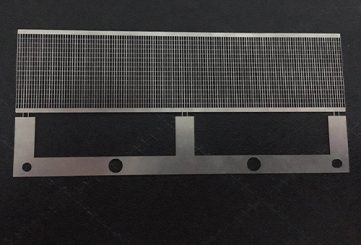

The SUS304 Endoscope Clip is a high-precision laser-cut medical component designed for use in endoscopic procedures. Manufactured using advanced five-axis laser cutting technology, this clip ensures exceptional accuracy, durability, and a burr-free finish. Crafted from medical-grade SUS304 stainless steel, it delivers reliable performance in demanding surgical environments. The laser-cut design provides smooth surfaces and precise geometries, ensuring secure tissue closure and minimal trauma during minimally invasive surgeries. Ideal for modern endoscopic applications, this clip meets the stringent requirements of contemporary healthcare.

الميزات الرئيسية:

- Ultra-Precise Cutting: Seam width of 18–30 µm with machining accuracy of ≤±10 µm for intricate designs.

- Burr-Free Finish: Smooth edges ensure safe application and minimal tissue trauma.

- High Durability: SUS304 stainless steel offers excellent corrosion resistance and long-term stability.

- Automated Production: Continuous feeding system ensures high efficiency and consistent quality.

- التوافق الحيوي: Meets standards for safe interaction with human tissues.

- Versatile Design: Tailored for secure tissue fixation in various endoscopic procedures.

Certification and Standards:

Certified under ISO 9001, ISO 13485, and ISO 10993 for quality management and biocompatibility. Compliant with CE and FDA regulations for medical device safety and efficacy.

Stainless Steel SUS304:

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- التوافق الحيوي: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

Cobalt-Chromium Alloys (L605):

Cobalt-Chromium Alloys (L605) are medical-grade materials valued for their exceptional strength, corrosion resistance, and biocompatibility. With tensile strength ranging from 800–1500 MPa and hardness of 300–550 HV, they ensure durability in demanding medical applications. Ideal for implants and surgical tools, they support direct tissue contact with minimal reaction. Laser-machined surfaces provide smooth, burr-free finishes, enhancing performance in sensitive procedures.

Nickel-Titanium alloy:

النيتينول (NiTi)، وهو سبيكة من النيكل والتيتانيوم، مشهور بمرونته الفائقة وذاكرته الشكلية، مما يجعله رائدًا في التطبيقات الطبية. بفضل قوة شد تصل إلى 1200 ميجا باسكال ومعامل مرونة يتراوح بين 40 و75 جيجا باسكال، يتفوق النيتينول في البيئات الصعبة.

Aluminum alloy:

Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

Magnesium alloy:

Magnesium, a lightweight (1.74 g/cm³) and biodegradable metal, is ideal for temporary medical implants like stents and orthopedic screws. Alloys such as WE43 or JDBM offer tensile strength (200–420 MPa) and controlled degradation (6–24 months), safely dissolving into non-toxic byproducts (Mg²⁺ ions). Its biocompatibility (ISO 10993) and ability to support tissue regeneration make it suitable for cardiovascular and bone repair applications. Magnesium’s elastic modulus closely matches bone, minimizing stress shielding in orthopedic uses.

Lithium (Li):

A lightweight, highly reactive metal used in medical devices like batteries for implants. Its high energy density and biocompatibility make it ideal for powering pacemakers and neurostimulators.

Copper (Cu):

A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

Iron (Fe):

A strong, durable metal used in some surgical instruments and structural components. Its high strength and cost-effectiveness make it suitable for non-implantable medical tools.

Ceramic:

A biocompatible, wear-resistant material used in orthopedic and dental implants. Its hardness, corrosion resistance, and bioinert properties ensure long-term stability and tissue compatibility.

- Endoscopic Procedures: Essential for secure tissue closure in gastrointestinal, urological, and thoracic surgeries.

- Minimally Invasive Surgery: Supports precise clip placement in laparoscopic and endoscopic operations.

- Hemostasis: Used for effective bleeding control during surgical interventions.

- Medical Device Manufacturing: Incorporated in the production of high-precision endoscopic instruments.

- Gynecological Applications: Suitable for tissue fixation in minimally invasive gynecological procedures.

- Material: SUS304 Stainless Steel

- Cutting Seam Width: 18–30 µm

- Machining Accuracy: ≤±10 µm

- Surface Roughness: Ra <0.2 µm

- Manufacturing Process: Five-axis laser cutting with automated feeding

- Operating Temperature: -20°C to 300°C, suitable for sterilization

- Degradation: Non-degradable, designed for long-term stability