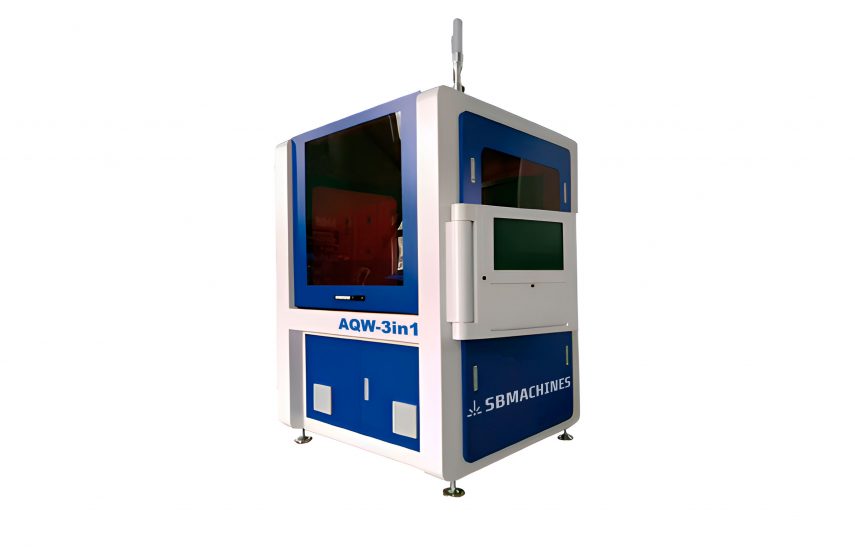

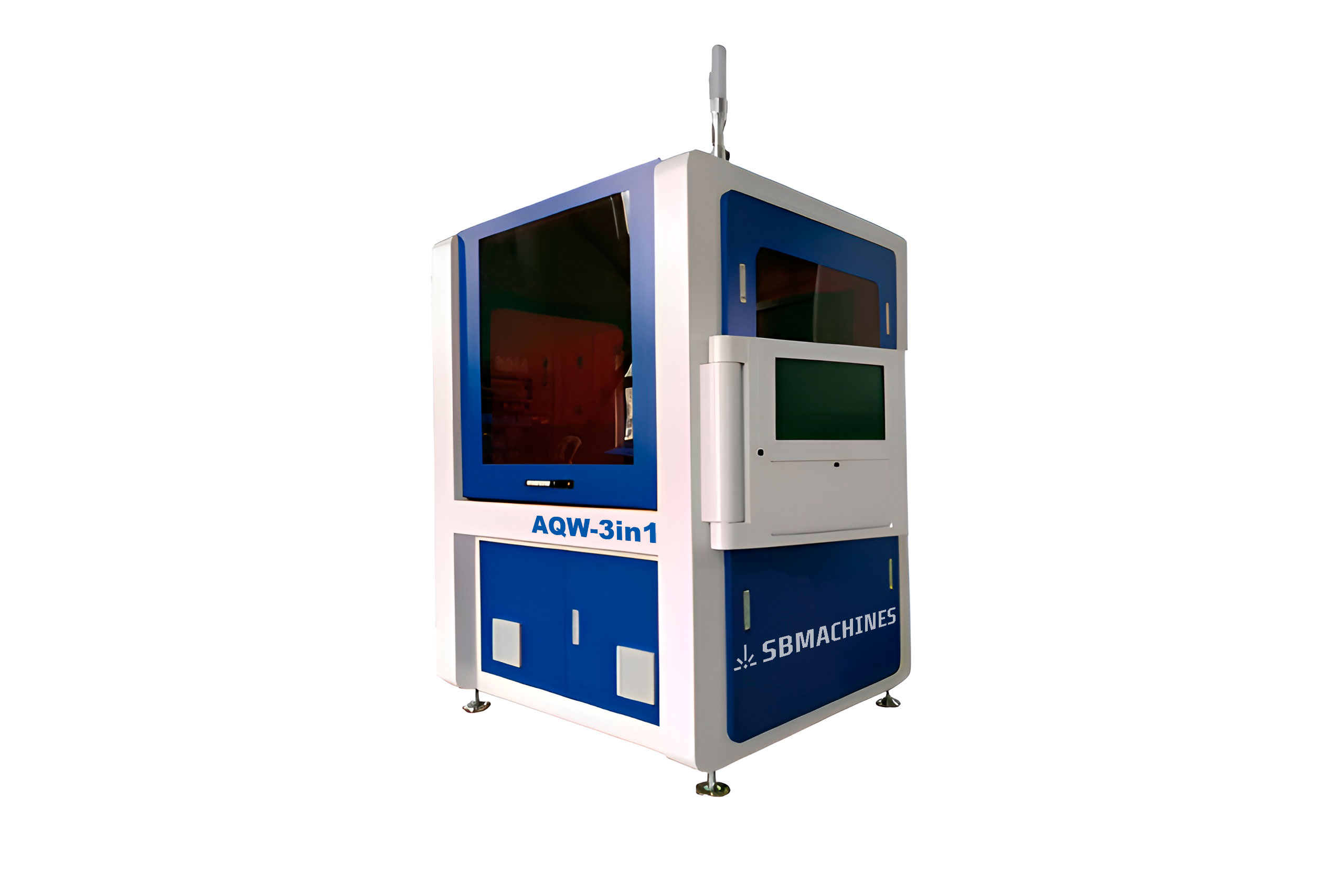

آلة لحام شعاع الليزر AQW-3in1 للمعدات الطبية المعدنية الدقيقة

AQW-3in1 Laser-Beam Welding Machine for Precision Metal Medical Equipment – Versatile Micro-Welding Solution

The AQW-3in1 is designed as a high-precision, all-in-one laser welding, cutting, and marking platform tailored for the demanding needs of medical metal device manufacturing. It supports seamless transitions between functions without compromising on accuracy or stability, making it ideal for assemblies, joints, and fine features in surgical and minimally invasive devices.

This machine combines stable laser delivery, precise motion control, and smart process orchestration to deliver clean welds with minimal thermal distortion. Its configuration flexibility enables compatibility with both automated production lines and bespoke device assembly setups.

Scope of application

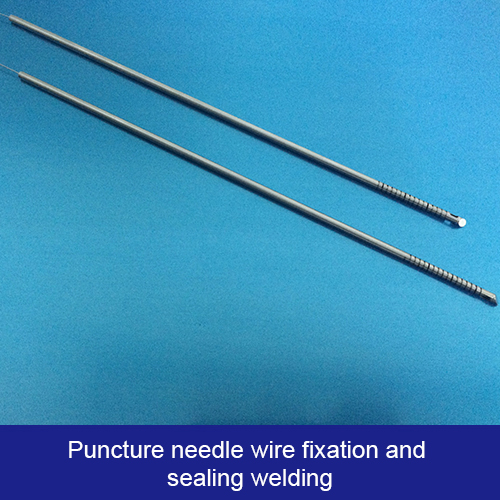

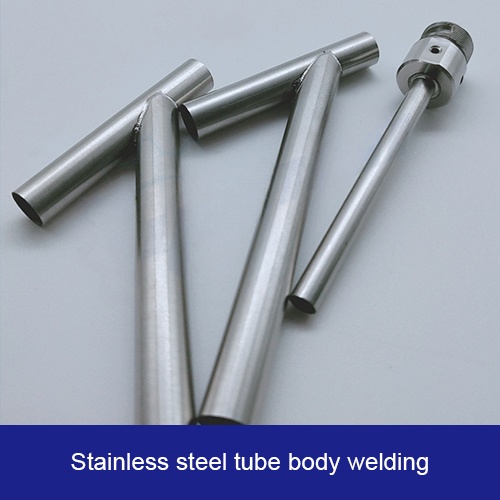

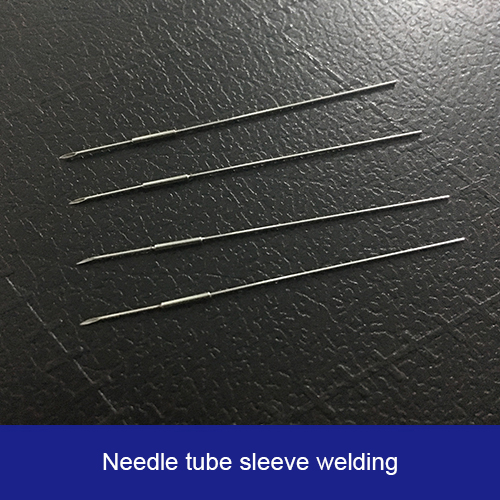

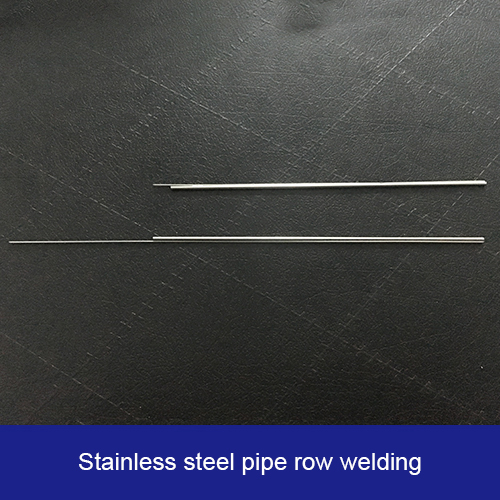

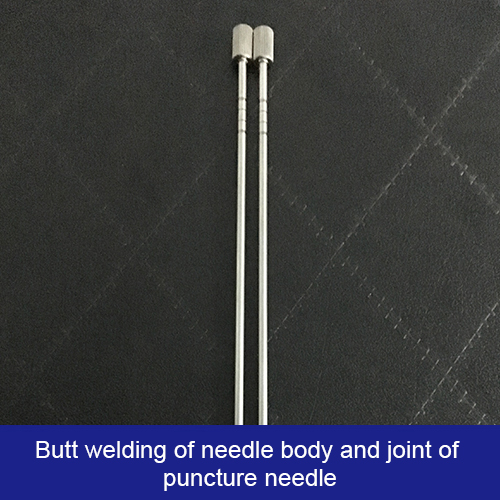

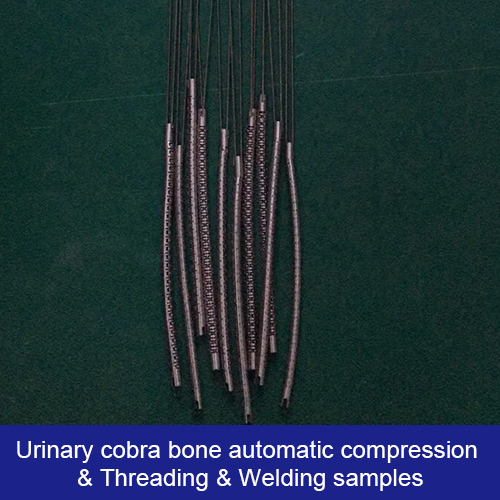

The AQW-3in1 is suitable for fine welding and joining tasks in medical component manufacturing, including ultrasonic knives, needle tubes, puncture needles, stents, stone extraction nets, endoscopic bone (snake bone), and miniature brackets. It supports butt welding, sleeve welding, and row welding applications for small and delicate metal parts.

High precision welding

- Small welding spots down to < Ø200 µm for minimal joint area

- High precision: radial run-out in rotary parts < 10 µm

- Excellent weld appearance: smooth surface, no bumps, pits, discoloration or deformation

- Pneumatic automatic control for precise clamping of thin-walled tubes and compatibility with tube loading/unloading automation

High finishing

This system ensures welds of exceptional surface integrity by tightly controlling laser parameters, beam alignment, and thermal input. It is engineered to produce smooth, consistent joints even on micro-scale structures, reducing post-weld finishing.

Advantages:

- Clean, smooth weld seams without bumps or pits

- Minimal heat-affected zones, preserving material properties

- Highly stable weld quality over repeated cycles

Strong adaptability

The AQW-3in1 can process equal-diameter tubes, deformed tubes, semi-finished tubes, and flat parts alike. It supports a wide variety of medical-grade materials, including stainless steel, nickel-titanium (nitinol), platinum-iridium, tantalum, cobalt-base alloys, aluminum, copper, and other alloys. Its pneumatic and automatic clamping systems allow flexible adaptation to various tube geometries and sizes without mechanical overhaul.

It also integrates a proprietary laser micromachining CAM (2D & 2.5D) system that enables efficient programming and process control tailored to each part’s requirements.

Flexible design

The machine is built with ergonomic and compact design considerations, allowing it to fit into modern production environments while maintaining intuitive operation. Optional features include machine vision for dynamic positioning and real-time monitoring, as well as modular software/hardware configurations to support personalized workflows and smart manufacturing management.

- Optional vision system for real-time process monitoring and laser positioning

- Flexible combination of software and hardware functions for customization

- Open control architecture with intuitive interface for efficient operation

Technical certification

The AQW-3in1 is manufactured to comply with medical device production standards and holds ISO 9001 and ISO 13485 certifications. It supports traceability, clean-room compatibility, and adheres to regulatory safety controls. Its robust design ensures stable processes, documented repeatability, and seamless integration into quality-controlled manufacturing environments.

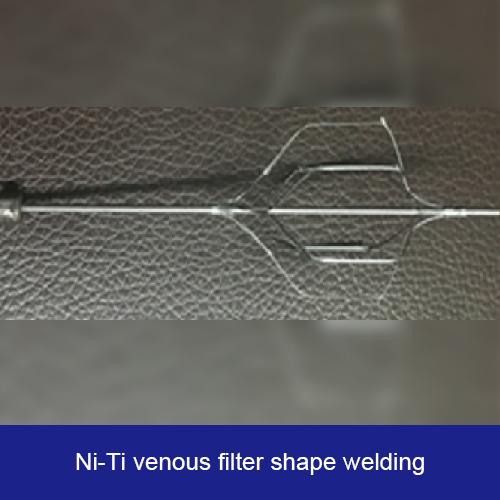

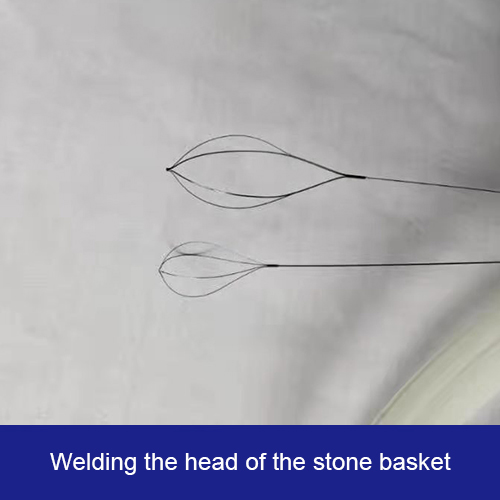

Sample display

Processing Materials:

- الفولاذ المقاوم للصدأ

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- التوافق الحيوي: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

- Nickel Titanium النيتينول (NiTi)، وهو سبيكة من النيكل والتيتانيوم، مشهور بمرونته الفائقة وذاكرته الشكلية، مما يجعله رائدًا في التطبيقات الطبية. بفضل قوة شد تصل إلى 1200 ميجا باسكال ومعامل مرونة يتراوح بين 40 و75 جيجا باسكال، يتفوق النيتينول في البيئات الصعبة.

- Platinum Iridium Platinum-Iridium is a biocompatible, corrosion-resistant alloy with exceptional durability and conductivity. Ideal for precision laser welding, it ensures strong, smooth joints for critical medical components like stone basket heads.

- التنتالوم Tantalum is a highly corrosion-resistant, biocompatible metal with excellent strength and ductility. Ideal for precision laser welding, it ensures robust, smooth joints for critical medical components like implants and surgical instruments, offering superior radiopacity and durability.

- Cobalt Base Alloys Cobalt Base alloys are highly durable, corrosion-resistant materials with excellent strength and biocompatibility. Perfect for precision laser welding, they provide robust, smooth welds for medical components like stone retrieval baskets.

- الألومنيوم Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

- نحاس A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

Laser Specifications:

- Fiber-Optic Laser

- Wavelength: 1030~1070nm±10nm

- Power Options: 80W, 100W, 200W, 300W, QCW150W

- Single Pulse Maximum Energy: 50J

Sıkıştırma sistemleri:

- Precision pneumatic automatic clamping for thin-walled pipes

- Customizable clamping system for larger pipes

Scope of Use

Fine welding of medical equipment components, including:

- Ultrasonic Knives

- Needle Tubes

- Puncture Needles

- Stents

- Stone Extraction Nets

- Endoscopic "Snake Bone" Components

Processing Capabilities

- High-Precision Welding Techniques:

- Butt Welding

- Sleeve Welding

- Row Welding

- Small Welding Spot: Φ100~300 μm

- Radial Runout: <10 μm for Rotary Tube Instruments

- Weld Quality:

- Smooth Surface

- No Deformation, Bumps, Pits, or Discoloration

Industries Served

- Interventional Medical Equipment Manufacturing

- Surgical and Diagnostic Instrument Production

Performance and Efficiency

- Maximum Operating Speeds:

- X, Y, Z Axes: 50mm/s

- θ-Axis: 500rpm

- Welding Parameters:

- Depth: 0.1~1.0mm

- Pulse Width: 0.1~20ms

- Frequency: 1~20Hz

Precision and Flexibility

- Accuracy and Repeatability:

- Positioning Accuracy: ±5μm

- Repeatability: ±3μm

- Processing Range:

- Pipe Processing: 0.1–7.0mm; 1.0–16.0mm (Optional, Customizable Clamps Available)

- Plane Processing: 300mm×300mm

- Wall Thickness: 0~1.0±0.02mm

Customizable Features

- Precision Visual Positioning and Monitoring System for Accurate Machining

- Real-Time Monitoring with Machine Vision System

- Compatibility with DXF and DWG File Formats

Certified Quality

- ISO9001

- ISO13485

Design and Usability

- Ergonomic and Compact Design

- Flexible Software and Hardware Configuration for Personalized Functionality

- Intuitive Interface for Efficient Operation and Intelligent Production Management