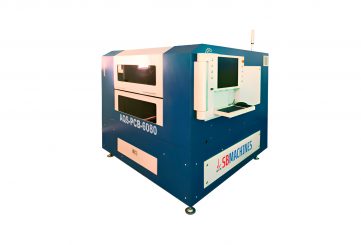

Máquina de corte láser AQS-HB-6045 para materiales duros y frágiles de precisión

- Table size (mm): 300mm*300mm; (larger format requirements support customization)

- WT: 0~2.0±0.02 mm

- Materials: Alumina & Zirconia & Aluminum Nitride & Zirconium Nitride & Silicon Nitride & Diamond & Sapphire & Silicon & Germanium & Gallium Arsenide & Tungsten Steel, etc.;

- Source type: Fiber

- Option:

Scope of application

Micromecanizado láser de cerámica, zafiro, diamante, acero de tungsteno y otros instrumentos de superficie plana y regular de alta dureza y alta fragilidad.

High finishing

- Cutting seam width: 15~30um

- High machining accuracy: ≤±10um

- Good incision quality: smooth incision & small heat-affected zone & few burrs & edge chipping <15um

- Size refinement: minimum product size 100um

Strong adaptability

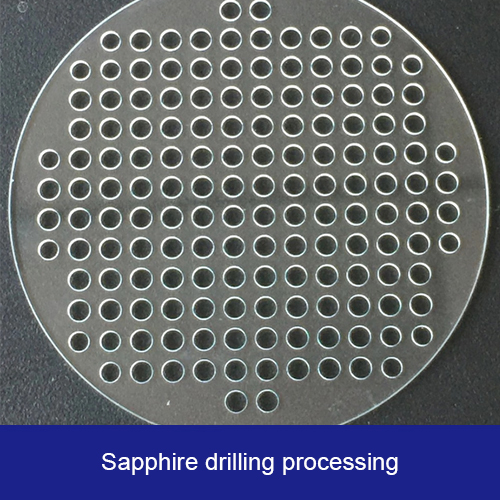

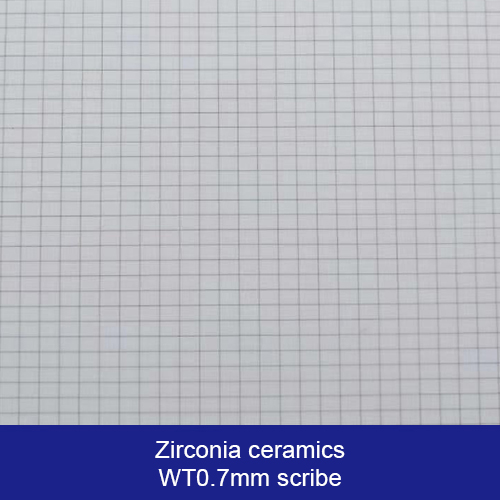

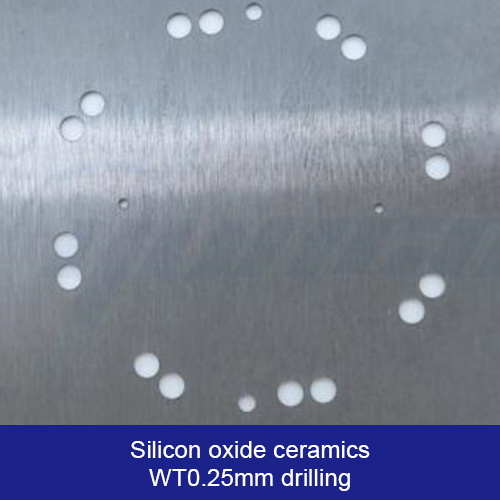

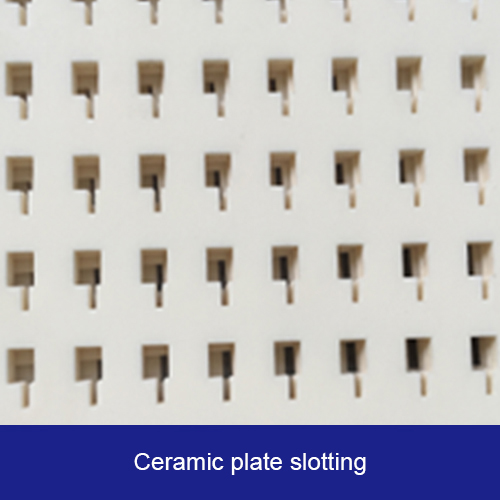

- Possess the ability of fine processing technology such as laser cutting, drilling, slotting, scribing and so on for flat & curved instruments

- Machinable alumina & zirconia & aluminum nitride & silicon nitride & diamond & sapphire & silicon & gallium arsenide & tungsten steel and other materials

- Equipped with self-developed direct-drive mobile double-drive precision motion platform, granite platform, aluminum alloy & granite beam for selection

- Provide optional functions such as double station & visual positioning & automatic loading and unloading system & processing dynamic monitoring

- Equipped with self-developed long & short focal length sharp & flat fine laser cutting head

- Configure modular feed and dust ductwork

- Provide self-developed movable tension frame & fixed tension frame & vacuum adsorption & honeycomb panel and other fixture options

- Equipped with self-developed laser micromachining 2D & 2.5D & 3D CAM software system

Flexible design

- Follow the ergonomic design concept, exquisite and concise

- Flexible combination of software & hardware functions, support personalized function configuration & intelligent production management

- Support forward innovative design from component level to system level

- Open Control & Laser Micromachining Software System Easy Operation & Intuitive Interface

Technical certification

- THIS

- ISO9001

- IATF16949

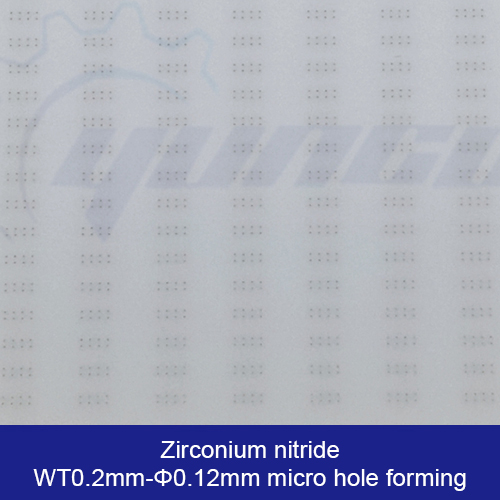

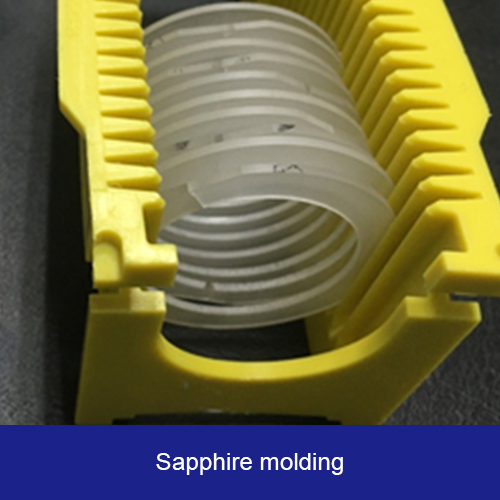

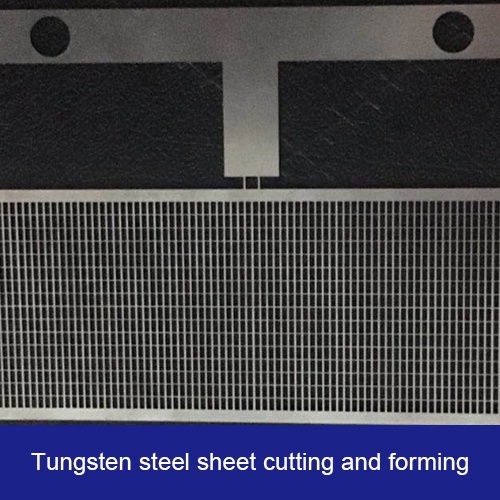

Sample Display

Materiales

-

Processing Materials:

- Alumina

- Zirconia

- Aluminum Nitride

- Silicon Nitride

- Diamond

- Sapphire

- Silicon

- Germanium

- Gallium Arsenide

- Tungsten Steel

-

Laser Specifications:

- Fiber-optic laser

- Wavelength: 1030~1070±10nm

- Power Options: CW1000W, QCW150W, QCW300W, QCW450W

- Cutting Seam Width: 15~30μm

- Material Wall Thickness: 0~2.0±0.02mm

Solicitud

-

Scope of Use:

- Laser micromachining of high-hardness and high-brittleness materials

- Processing flat and regular surface instruments made of ceramics, sapphire, diamond, tungsten steel, and others

-

Processing Capabilities:

- High machining accuracy: ≤±10μm

- Smooth incision with minimal heat-affected zone

- Edge chipping: <15μm

- Minimum product size: 100μm

-

Industries Served:

- Semiconductor manufacturing

- Electronics production

- Precision engineering

Presupuesto

Performance and Efficiency

Maximum Operating Speeds:

- X, Y1, Y2 Axes: 1000mm/s

- Z Axis: 50mm/s

Positioning Accuracy:

- ±3μm (X, Y1, Y2)

- ±5μm (Z)

Repeatability:

- ±1μm (X, Y1, Y2)

- ±3μm (Z)

Advanced Features

- Self-developed direct-drive motion platform with precision control

- Optional visual positioning and dynamic monitoring systems

- Modular feed and dust ductwork

- Multiple fixture options: vacuum adsorption, honeycomb panels, tension frames

Certified Quality

- ISO9001

- IATF16949

Design Excellence

- Ergonomic and compact design

- Flexible hardware and software configuration for customized needs

- User-friendly interface with self-developed 2D, 2.5D, and 3D CAM software systems