Ni-Ti Venous Filter Shape Welding

- High Adaptability: Precision visual positioning.

- Ergonomic Design: Machine vision monitoring.

- Customizable: Intelligent production management.

- Certified Quality: ISO9001 and ISO13485 certified.

Descripción del Producto

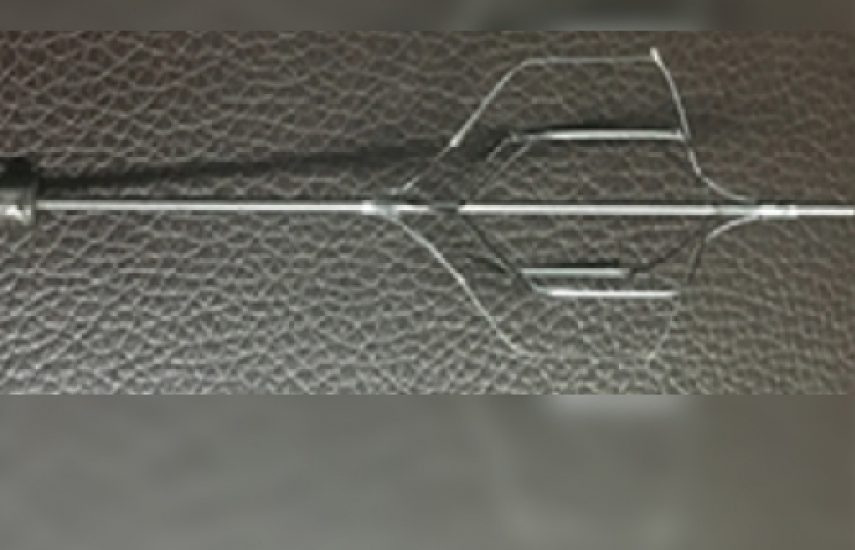

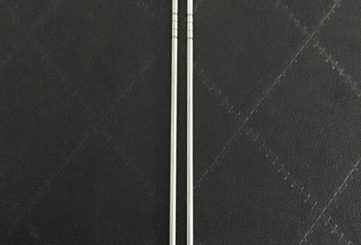

El Ni-Ti Venous Filter Shape Welding is a high-precision laser welding solution designed for creating strong and seamless welds on nickel-titanium (Ni-Ti) venous filters. Utilizing advanced laser-beam welding technology, this process ensures exceptional accuracy, smooth finishes, and consistent results. It is ideal for medical equipment requiring precise and reliable welding.

Características principales:

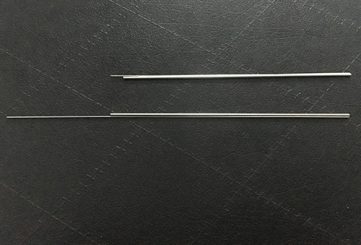

- Alta precisión: Welding spot <Ø200µm.

- Acabado liso: No deformation, bumps, or discoloration.

- Procesamiento eficiente: Pneumatic automatic control for precise clamping.

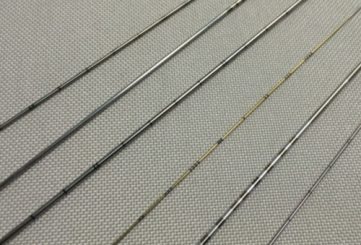

- Versatilidad del material: Compatible with nickel-titanium and other alloys.

- Tecnología avanzada: Manufactured using 2D and 2.5D CAM software.

-

Níquel-titanio (Ni-Ti)

-

Stainless Steel

-

Platinum-Iridium

-

Tantalum

-

Cobalt Base

-

Aluminum

-

Copper

El Ni-Ti Venous Filter Shape Welding Se utiliza ampliamente en la industria médica para:

-

Venous filters

-

Precision welding

-

instrumentos quirúrgicos

-

Medical equipment