Plastic Pipe Cutting

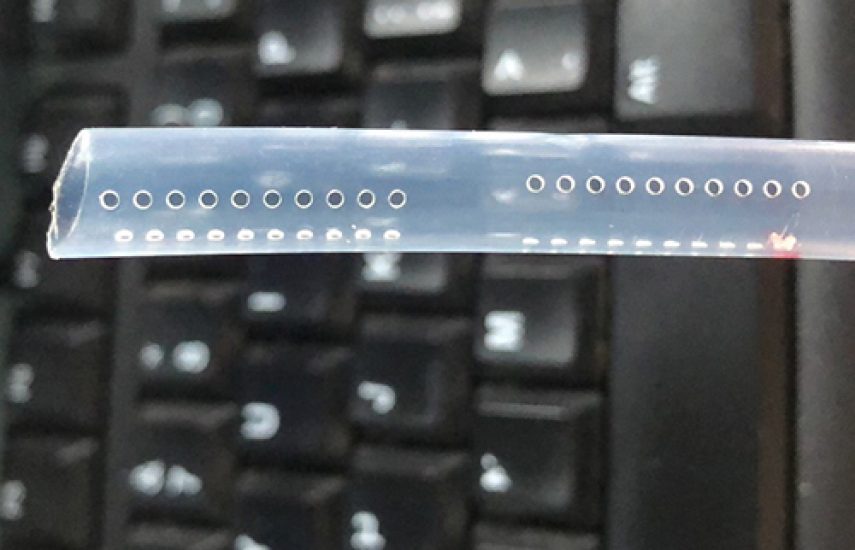

Plastic Pipe Cutting – Precision Laser Cutting for Medical Applications

Plastic Pipe Cutting refers to the advanced laser-based process of precisely shaping and cutting plastic pipes for medical devices, ensuring high accuracy and smooth, burr-free edges. This technology is utilized to produce intricate components for medical applications, leveraging state-of-the-art laser systems to meet the stringent requirements of the healthcare industry. By employing cutting-edge 5-axis laser cutting, this method delivers exceptional precision, enabling the creation of complex geometries with minimal material waste. Ideal for crafting components used in surgical instruments, diagnostic equipment, and other critical medical devices, Plastic Pipe Cutting ensures reliability, biocompatibility, and compliance with medical standards.

תכונות עיקריות:

- PMMA (Acrylic): Offers crystal-clear edges with high optical clarity, perfect for transparent medical components requiring aesthetic precision.

- Polycarbonate: Provides fused, burr-free edges, ensuring durability and impact resistance for robust medical device parts.

- ABS: Enables high-precision cuts with excellent mechanical properties, ideal for structural components in medical equipment.

- Polypropylene: Supports flexible and lightweight designs with chemical resistance, suitable for fluid-handling medical applications.

- Delrin (POM): Delivers smooth, precise cuts with high stiffness and low friction, perfect for moving parts in medical devices.

- Polyamide (PA): Offers strength and flexibility, enabling intricate designs for durable medical components.

- Polyethylene (PE): Ensures clean cuts with excellent chemical resistance, ideal for disposable medical tubing.

- Polyester: Provides burr-free edges with high dimensional stability, suitable for precision medical films and components.

Certification and Standards:

Compliant with ISO 13485 and other relevant medical manufacturing standards, ensuring quality and safety for medical applications.

Plastic Materials:

- Can cut a variety of plastic types, including PVC, PP, PE, and other engineered plastics.

Plastic Pipe Cutting is widely used in the medical industry for producing high-precision components such as surgical tubing, diagnostic device parts, and fluid delivery systems. It supports the creation of intricate designs for catheters, endoscopes, and other critical medical equipment, ensuring biocompatibility and reliability. The contact-free laser process minimizes contamination risks, making it ideal for sterile medical environments.

- Laser Type: CO2 laser for precise plastic cutting

- Cutting Accuracy: ≤±10μm

- Cutting Seam Width: 15–30μm

- Maximum Pipe Diameter: Up to 200 mm

- Maximum Pipe Length: Up to 3 meters

- Material Thickness: 0.5 mm to 10 mm

- Supported Materials: PMMA, Polycarbonate, ABS, Polypropylene, Delrin, Polyamide, Polyethylene, Polyester

- Automation: CNC-controlled with automated loading/unloading options

- Safety Features: Fully enclosed system for operator safety