חיתוך ועיצוב של צינור אליפטי בעל ארבעה צירים

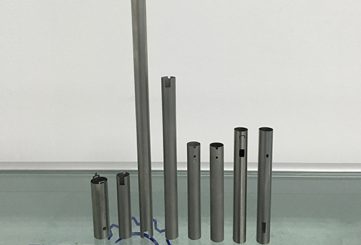

Four-axis Linkage Cutting and Forming of Oval Tube – Precision Shaping for Medical and Surgical Components

Four-axis Linkage Cutting and Forming of Oval Tube is a high-precision manufacturing process for creating oval-shaped tubes used in medical devices such as endoscopes and catheters. Utilizing advanced four-axis laser micromachining on medical-grade materials like SUS304 stainless steel, Nitinol, or Cobalt-Chrome alloys, this process delivers complex geometries with smooth, burr-free surfaces. It ensures exceptional durability, biocompatibility, and seamless integration into medical systems for minimally invasive procedures, meeting stringent quality standards.

תכונות עיקריות:

- דיוק אולטרה-גבוה: Achieves cutting seam widths of 15–30μm and accuracy of ≤±10μm for burr-free, precise oval tube structures.

- Complex Geometries: Four-axis linkage enables intricate oval tube designs tailored to specific medical applications.

- ביולוגיות תאימות: Hypoallergenic materials minimize tissue reaction, ideal for direct contact in sensitive procedures.

- Superior Durability: Offers high tensile strength and corrosion resistance for reliable performance in physiological environments.

- Efficient Integration: Compatible with various clamping systems and cutting methods for rapid assembly.

- Sterility Maintenance: Smooth finish reduces contamination risks and supports sterilization processes.

Certification and Standards:

Four-axis Linkage Cutting and Forming of Oval Tube complies with ISO 13485 quality management standards for medical devices and adheres to biocompatibility requirements under ISO 10993.

316L Stainless Steel:

316L Stainless Steel is a medical-grade austenitic chromium-nickel alloy renowned for its excellent corrosion resistance and biocompatibility. With a tensile strength of approximately 485–550 MPa and elongation up to 40%, it offers durability and flexibility without brittleness. Its low carbon content enhances weldability and resistance to intergranular corrosion, making it ideal for medical implants and instruments. Laser-machined for smooth, burr-free surfaces, it minimizes tissue irritation in sensitive applications.

Nickel-Titanium alloy:

ניטינול (NiTi), סגסוגת ניקל-טיטניום, ידועה באלסטיותה העל ובזיכרון הצורה שלה, מה שהופך אותה לפורצת דרך ביישומים רפואיים. עם חוזק מתיחה של עד 1200 מגה פסקל ומודול אלסטיות של 40-75 ג'יגה פסקל, ניטינול מצטיין בסביבות תובעניות.

Titanium alloys:

Titanium Alloys are medical-grade materials prized for their high strength-to-weight ratio, excellent corrosion resistance, and superior biocompatibility. With tensile strength ranging from 900–1200 MPa and good ductility, they provide durability and flexibility for demanding medical applications. Their bio-inert properties make them ideal for implants and instruments requiring direct tissue contact. Laser-machined surfaces ensure smooth, burr-free finishes, minimizing tissue irritation in sensitive procedures.

Cobalt-chrome alloy:

קובלט-כרום (CoCr), סגסוגת של קובלט וכרום, שלעתים קרובות משופרת במוליבדן, מוערכת בזכות חוזקה יוצא הדופן, עמידותה בפני קורוזיה ותאימותה הביולוגית. עם חוזק מתיחה הנע בין 800 ל-1500 מגה פסקל וקשיחות של 300 ל-550 HV, CoCr הוא אבן יסוד בטכנולוגיה הרפואית. דרגות פופולריות כמו L605 (Co-Cr-W-Ni) ו-MP35N (Co-Cr-Ni-Mo) משפרות את ביצועיה.

Aluminum alloy:

Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

- Medical Endoscopy: Facilitates precise tube forming for flexible endoscopic systems in gastrointestinal, biliary, or urological procedures.

- Minimally Invasive Surgery: Supports oval tube structures for enhanced maneuverability in catheter and guidewire systems.

- Endoscope Assembly: Integral to constructing variable endoscopic components with high-precision requirements.

- Medical Device Repair: Employed in maintenance or replacement of tube components in endoscopic and catheter systems.

- Specialized Medical Designs: Adaptable for investigational or custom devices needing advanced flexibility in cardiology or neurology.

- Material Composition: SUS304 stainless steel, Nitinol (NiTi), or Cobalt-Chrome (CoCr) alloys.

- Dimensions: Customizable diameter, length, and oval tube geometries based on application requirements.

- Cutting Seam Width: 15–30μm.

- Machining Accuracy: ≤±10μm.

- Manufacturing Process: Four-axis linkage laser micromachining with continuous automatic feeding for burr-free, smooth finish.

- Clamping Compatibility: D-type collets, ER-series collets, three-jaw chucks.

- Cutting Methods: Dry or wet cutting options.

- Packaging: Sterilized and individually packaged to maintain integrity.

- Storage Conditions: Store in a dry, cool environment to prevent corrosion.