Aluminum Substrate Cut

Aluminum Substrate Cut – Precision Laser Processing

This is a high-precision laser system for cutting aluminum substrates, ideal for electronics and medical applications, ensuring superior cut quality.

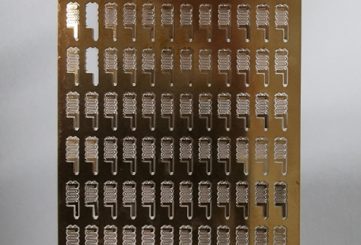

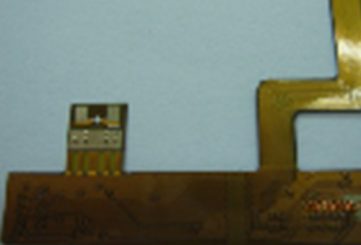

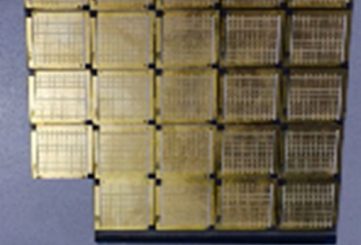

The Aluminum Substrate Cut system from AQ-Laser is an advanced laser processing solution designed for high-precision cutting of aluminum substrates used in electronics manufacturing. Tailored for industries such as medical device production, telecommunications, and consumer electronics, this system delivers clean, burr-free cuts with minimal thermal impact, ensuring exceptional edge quality. It is optimized for processing aluminum substrates, enabling intricate circuit designs and high-density interconnects (HDI) critical for high-performance applications. Equipped with automated features like precise positioning and focusing, it ensures efficient, high-quality production for advanced electronic components.

תכונות עיקריות:

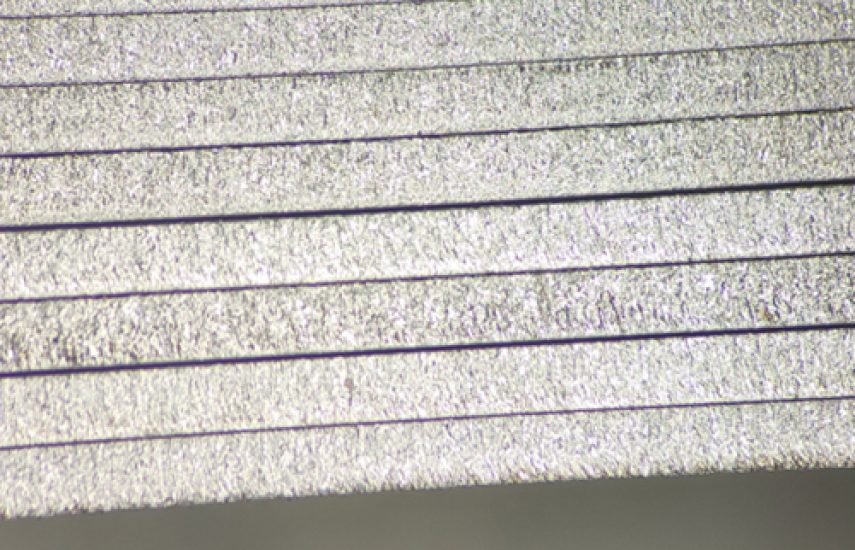

- High-Precision Cutting: Achieves cutting accuracy of ≤±10μm and seam widths of 15–30μm for intricate, burr-free designs.

- Material Optimization: Processes aluminum substrates with excellent thermal conductivity and lightweight properties.

- Low Thermal Impact: Advanced fiber laser technology minimizes heat-affected zones, preserving material integrity.

- Automated Efficiency: Includes automatic positioning, focusing, and feeding systems for streamlined production.

- CleanCut Technology: Ensures carbonization-free edges, enhancing technical cleanliness and reliability.

- עמידות בפני קורוזיה: Supports durable aluminum substrates resistant to environmental degradation.

Certification and Standards:

Certified to ISO9001 and IATF16949 standards, ensuring consistent quality for electronics and automotive applications. Compliant with CE marking and RoHS directives for safety and environmental sustainability.

Aluminum Substrate:

- Excellent Thermal Conductivity: Efficiently dissipates heat, ideal for high-power electronics like LED lighting and medical imaging devices.

- Lightweight: Reduces overall device weight, enhancing portability for applications in wearables and compact electronics.

- Cost-Effective: Offers a balance of performance and affordability, suitable for large-scale electronics manufacturing.

- Corrosion Resistance: Resists environmental degradation, ensuring durability in harsh conditions.

- Mechanical Strength: Provides robust support for circuit components, maintaining structural integrity under stress.

- Recyclability: Environmentally friendly, supporting sustainable manufacturing practices.

Copper Substrate:

- Superior Electrical Conductivity: Ensures efficient signal transmission, critical for high-frequency 5G antennas and power electronics.

- High Thermal Conductivity: Effectively manages heat dissipation, ideal for high-performance PCBs and medical devices.

- Ductility: Allows precise forming and shaping, enabling intricate designs for compact electronic assemblies.

- Durability: Resists wear and tear, providing long-term reliability in demanding applications.

- Solderability: Facilitates strong, reliable connections in circuit assembly, enhancing manufacturing efficiency.

- High-Density Interconnect Support: Enables complex, high-density circuit designs for advanced electronics.

Ceramic Substrate:

- Exceptional Thermal Stability: Withstands extreme temperatures, ideal for high-power and high-frequency electronics like RF modules.

- Superior Electrical Insulation: Prevents unwanted conductivity, ensuring reliable performance in sensitive medical and telecom devices.

- High Mechanical Strength: Maintains structural integrity under stress, supporting precision manufacturing of complex designs.

- Chemical Inertness: Resists corrosion from chemicals and environmental factors, ensuring long-term reliability.

- Low Dielectric Loss: Enhances signal integrity, making it perfect for high-frequency applications like 5G and radar systems.

- Biocompatibility: Suitable for medical implants and diagnostic equipment due to its non-reactive properties.

- High-precision cutting of aluminum substrates for medical devices and consumer electronics.

- Contour cutting and marking for high-performance printed circuit boards (PCBs).

- Processing of aluminum substrates for LED lighting and telecommunications equipment.

- Suitable for high-density interconnect (HDI) designs in automotive and aerospace applications.

- Laser Type: High-performance fiber laser

- Cutting Accuracy: ≤±10μm

- Cutting Seam Width: 15–30μm

- Material Compatibility: Aluminum substrates

- Processing Capabilities: Contour cutting, drilling, and marking

- Automation: Automatic positioning, focusing, and feeding systems

- Supported Formats: Gerber, DXF, DWG, SVG, and other 2D CAD formats