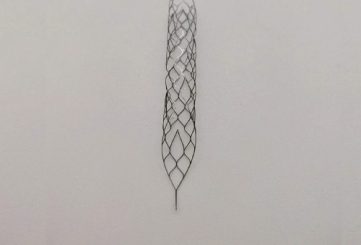

חריץ עיוור SUS WT-0.1 מ"מ רוחב 30um D50um

SUS WT-0.1mm W30µm D50µm Blind Slot – a high-precision stainless steel microgroove for medical and industrial use

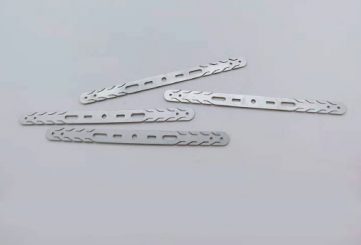

SUS WT-0.1mm W30um D50um Blind Slot – a high-precision component crafted from stainless steel (SUS) using advanced femtosecond laser micromachining technology. This component features micro-scale blind slots with a wall thickness (WT) of 0.1 mm, a slot width (W) of 30 µm, and a slot depth (D) of 50 µm. Designed for demanding applications in medical devices, microelectronics, and precision engineering, the blind slot structure ensures minimal material stress, superior surface quality, and exact dimensional control. Its biodegradable and biocompatible properties make it ideal for medical implants and other critical applications requiring high precision and reliability.

תכונות עיקריות:

- Precision Manufacturing: Femtosecond laser cutting ensures ultra-fine slot dimensions (30 µm width, 50 µm depth) with tolerances of ≤±5 µm.

- High-Quality Surface: Burr-free edges and smooth surfaces reduce tissue trauma in medical applications and enhance component reliability.

- Biocompatibility: Meets ISO 10993 standards, ensuring safe interaction with human tissues for medical implants.

- Customizable Design: Blind slot configuration can be tailored to specific application needs, enhancing functionality.

- Corrosion Resistance: Stainless steel (SUS) provides excellent resistance to corrosion, ideal for harsh environments.

- Lightweight and Durable: Thin wall thickness (0.1 mm) balances strength and reduced mass for optimal performance.

Certification and Standards:

- ISO 9001: Certified for quality management in manufacturing processes.

- ISO 13485: Meets international standards for medical device manufacturing.

- ISO 10993: Compliant with biocompatibility standards for safe human use.

- CE Marking: Conforms to EU regulations for medical devices, ensuring safety and efficacy.

- FDA Clearance: Pending or achieved, depending on market requirements for use in the United States.

Stainless Steel (SUS): High-purity SUS alloy, typically 316L or similar grades, known for exceptional corrosion resistance due to a passive chromium oxide layer.

- Mechanical Strength: Tensile strength of 500–1000 MPa and hardness of 200–350 HV, ensuring durability under dynamic loads.

- ביולוגיות תאימות: Non-toxic and non-reactive, ideal for long-term implantation or contact with biological tissues.

- Thermal Stability: Maintains structural integrity across a wide temperature range, suitable for sterilization processes.

- Surface Finish: Achieves a polished, burr-free finish with surface roughness (Ra) <0.2 µm, critical for medical and precision applications.

- Medical Implants: Used in cardiovascular devices, orthopedic implants, and dental applications due to biocompatibility and precision.

- Microelectronics: Ideal for micro-scale components in sensors, connectors, and circuit boards requiring precise slotting.

- Microfluidics: Employed in lab-on-chip devices and fluid control systems for accurate channel formation.

- הנדסת דיוק: Suitable for aerospace, automotive, and optical systems needing high-tolerance components.

- Surgical Tools: Incorporated in minimally invasive tools, such as catheters and endoscopes, for enhanced functionality.

- Wall Thickness (WT): 0.1 mm

- Slot Width (W): 30 µm

- Slot Depth (D): 50 µm

- Material: High-purity stainless steel (SUS, e.g., 316L)

- Manufacturing Process: Femtosecond laser micromachining for ultra-precise slot formation

- Surface Roughness: Ra <0.2 µm

- Tolerances: ≤±5 µm for slot dimensions

- Degradation: Non-degradable, designed for long-term stability

- Operating Temperature: -20°C to 300°C, suitable for sterilization and harsh environments