Copper Substrate Cutting and Forming

Copper Substrate Cutting and Forming – Precision Laser Processing for High-Conductivity Electronics

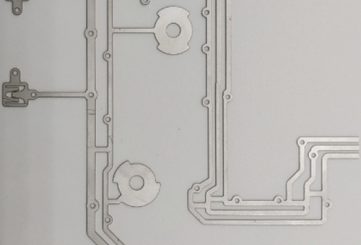

Copper Substrate Cutting and Forming is a high-precision laser machining process designed to create intricate components from copper substrates for medical and electronic applications. Utilizing advanced fiber laser technology with nitrogen assist, this process delivers clean, burr-free cuts and precise forming with minimal thermal distortion. Crafted from high-quality copper, known for its superior electrical and thermal conductivity, the resulting components are ideal for medical sensors, electronic circuits, and high-performance interconnects. The laser-cut design ensures smooth edges and complex patterns, optimizing performance in demanding environments. Tailored for high-precision applications, this process meets the rigorous standards of modern healthcare and electronics manufacturing.

תכונות עיקריות:

- Ultra-Precise Cutting: Seam width of 15–30 µm with machining accuracy of ≤±10 µm for intricate circuit designs.

- Burr-Free Edges: Smooth surfaces ensure reliable performance and safe integration in sensitive applications.

- High Conductivity: Copper substrates provide excellent electrical and thermal conductivity for high-performance electronics.

- Minimal Thermal Impact: Fiber laser with nitrogen assist minimizes oxidation and thermal distortion for enhanced material integrity.

- רבגוניות חומרית: Compatible with copper foils and copper-clad laminates for diverse applications.

- Automated Production: Direct-drive XY motion platform ensures high efficiency and consistent quality.

Certification and Standards:

Certified under ISO 9001 and IATF 16949 for quality management. Compliant with CE and FDA regulations for medical device safety and efficacy.

Aluminum Substrate:

- Excellent Thermal Conductivity: Efficiently dissipates heat, ideal for high-power electronics like LED lighting and medical imaging devices.

- Lightweight: Reduces overall device weight, enhancing portability for applications in wearables and compact electronics.

- Cost-Effective: Offers a balance of performance and affordability, suitable for large-scale electronics manufacturing.

- Corrosion Resistance: Resists environmental degradation, ensuring durability in harsh conditions.

- Mechanical Strength: Provides robust support for circuit components, maintaining structural integrity under stress.

- Recyclability: Environmentally friendly, supporting sustainable manufacturing practices.

Copper Substrate:

- Superior Electrical Conductivity: Ensures efficient signal transmission, critical for high-frequency 5G antennas and power electronics.

- High Thermal Conductivity: Effectively manages heat dissipation, ideal for high-performance PCBs and medical devices.

- Ductility: Allows precise forming and shaping, enabling intricate designs for compact electronic assemblies.

- Durability: Resists wear and tear, providing long-term reliability in demanding applications.

- Solderability: Facilitates strong, reliable connections in circuit assembly, enhancing manufacturing efficiency.

- High-Density Interconnect Support: Enables complex, high-density circuit designs for advanced electronics.

Ceramic Substrate:

- Exceptional Thermal Stability: Withstands extreme temperatures, ideal for high-power and high-frequency electronics like RF modules.

- Superior Electrical Insulation: Prevents unwanted conductivity, ensuring reliable performance in sensitive medical and telecom devices.

- High Mechanical Strength: Maintains structural integrity under stress, supporting precision manufacturing of complex designs.

- Chemical Inertness: Resists corrosion from chemicals and environmental factors, ensuring long-term reliability.

- Low Dielectric Loss: Enhances signal integrity, making it perfect for high-frequency applications like 5G and radar systems.

- Biocompatibility: Suitable for medical implants and diagnostic equipment due to its non-reactive properties.

- Medical Sensors: Produces precision components for wearable and diagnostic medical devices.

- Electronic Circuits: Creates intricate layouts for consumer electronics and high-density interconnects.

- Diagnostic Equipment: Supports high-precision substrates for imaging and laboratory devices.

- Industrial Electronics: Used in robust components for control systems and power electronics.

- Medical Device Manufacturing: Incorporated in the production of advanced electronic substrates.

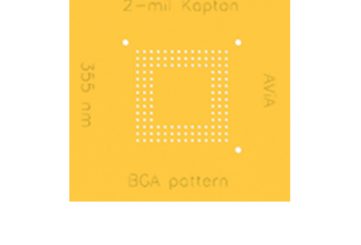

- Material: Copper Foil, Copper-clad Laminates

- Thickness: 0.05–0.5 mm

- Cutting Seam Width: 15–30 µm

- Machining Accuracy: ≤±10 µm

- Surface Roughness: Ra <0.2 µm

- Manufacturing Process: Fiber laser cutting with nitrogen assist and automated feeding

- Operating Temperature: -20°C to 150°C, suitable for high-performance applications

- Degradation: Non-degradable, designed for long-term stability