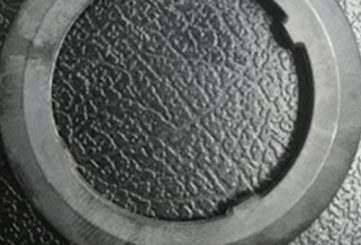

Прорезка керамической пластины

- High Accuracy: Machining precision of ≤±10µm ensures flawless results.

- Durability: Ceramic materials provide exceptional wear resistance and longevity.

- Customizable: Supports various shapes, sizes, and configurations to meet specific needs.

- Экологичность: Разработано для минимального количества отходов и энергоэффективного производства.

Описание продукта

Ceramic Plate Slotting is a precision machining process designed for creating slots and grooves in ceramic plates. Utilizing advanced laser micromachining technology, this process ensures high accuracy, smooth edges, and minimal thermal damage. Ideal for industries requiring durable and high-performance components, this solution is perfect for applications in electronics, medical devices, and industrial tools.

Основные характеристики:

- Высокая точность: Slotting accuracy of ≤±10µm ensures consistent and reliable results.

- Exceptional Durability: Ceramic materials offer superior hardness and wear resistance.

- Гладкая отделка: Cutting seam width of 15~30µm with minimal burrs and edge chipping (<15µm).

- Универсальность: Suitable for flat and curved surfaces, with compatibility for 2D, 2.5D, and 3D machining.

- Эффективная обработка: Modular feed and dust ductwork enhance productivity and cleanliness.

-

Основной материал: High-quality ceramics (alumina, zirconia, silicon nitride, etc.).

-

Совместимые материалы: Sapphire, silicon, gallium arsenide, and other hard, brittle materials.

Ceramic Plate Slotting is widely used in the following industries:

-

Electronics: Precision components for semiconductors and microelectronics.

-

Медицинские приборы: Surgical tools, implants, and diagnostic equipment.

-

Industrial Tools: Cutting, drilling, and forming tools for heavy-duty applications.

-

Optics: Precision slots for lenses and optical components.

-

Автомобильная промышленность: High-strength parts for engines and braking systems.