AQT-ND Центр лазерной обработки медицинских игл

- Diameter (mm): 0,1-7,5 & 1-16

- Processing length (mm): 300

- Source type: Fiber-optic laser

- Axis: 3

- Power: Up 500W

Область применения

Лазерная микрообработка различных типов игл, включая установочные иглы, пункционные иглы и иглы для радиочастотной абляции.

Высокая отделка

- Cutting seam width: 18~30um

- Высокая точность обработки: ≤±10 мкм

- Good cut quality: no burrs & smooth cut

- High processing efficiency: one-time cutting through one-sided pipe wall & continuous automatic feeding processing

Высокая приспособляемость

- Possess the ability of fine processing technology such as laser dry cutting & wet cutting & drilling & grooving

- Support centripetal & vertical & compound opening feature processing of equal diameter tube & reducer tube & flat instrument

- Can process various alloy materials such as 304&316L&Ni-Ti&L605

- Machinable equal-diameter tubes & deformed tubes & semi-finished tubes & small-format flat instruments

- Compatible with precision thin-walled tube clamping systems such as precision D-type collets & ER series collets & three-jaw chucks

- Combined Precision Thin-Walled Tube Bushing Support System Using Adaptive Shape Tolerance Changes

- Provide supporting solutions such as continuous automatic feeding processing & automatic loading and unloading of precision thin-walled tubes

- Оснащен собственной разработкой программного обеспечения CAM для лазерной микрообработки 2D, 2.5D и 3D.

Гибкий дизайн

- Следуйте эргономичной концепции дизайна, изысканной и лаконичной.

- Provides the optional function of machine vision system for real-time online monitoring of laser dynamic processing process

- Гибкое сочетание функций программного обеспечения и оборудования, поддержка персонализированной конфигурации функций и интеллектуального управления производством

- Поддержка инновационного проектирования от уровня компонентов до уровня системы

- Открытое управление и система программного обеспечения для лазерной микрообработки Простота эксплуатации и интуитивно понятный интерфейс

Техническая сертификация

- ЭТОТ

- ISO9001

- ISO13485

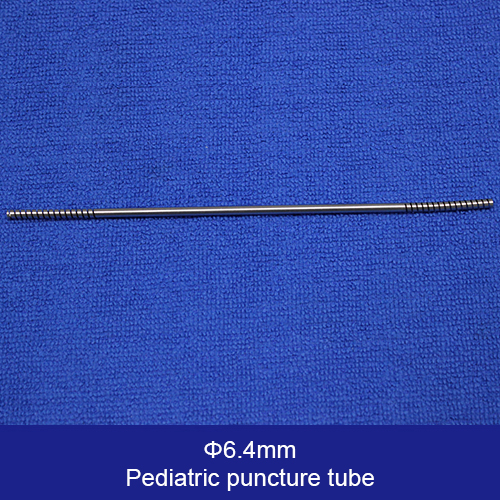

Sample display

Материалы

-

Обрабатываемые материалы:

- 304 Stainless Steel

- Нержавеющая сталь 316L

- Ni-Ti Alloys

- L605 Alloy

- Other Alloys

-

Clamping Systems:

- Precision D-Type Collets

- ER Series Collets

- Three-Jaw Chucks

-

Характеристики лазера:

- Fiber-Optic Laser

- Wavelength: 1030~1070nm±10nm

- Power Options: 100W, 200W, 250W, 300W, 500W

Приложение

Scope of Use

- Laser Micromachining for Needles:

- Indwelling Needles

- Puncture Needles

- Radiofrequency Ablation Needles

- Processing of Tubes and Instruments:

- Equal-Diameter, Deformed, and Semi-Finished Tubes

- Small-Format Flat Instruments

Processing Capabilities

- Laser Cutting, Drilling, and Grooving

- High Finishing: Cutting Seam Width 15~25 μm

- High Machining Accuracy: ≤ ±10 μm

- Continuous Automatic Feeding Processing

- One-Time Cutting Through One-Sided Pipe Wall

Industries Served

- Medical Equipment Manufacturing

- Surgical Instrument Production

Технические характеристики

Производительность и эффективность

- Максимальные рабочие скорости:

- X-Axis: 300 mm/s

- Y and Z-Axis: 100 mm/s

- θ-Axis: 600 rpm

Precision and Versatility

- Точность позиционирования: ±2~±3 μm

- Повторяемость: ±0.5~±1 μm

- Processing Wall Thickness: 0~0.5 ± 0.02 mm

- Pipe Diameter Processing Range:

- 0.1~7.5 mm

- 0.3~16.0 mm

Customizable Features

- Tube Blank Length: <2.5 m (Customizable Fixtures Available)

- Single Processing Range: 0~300 mm (Segmented Splicing for Longer Products)

- Compatible File Formats: DXF, DWG

Сертифицированное качество

- ISO9001, ISO13485 Certifications

Design and Usability

- Ergonomic and Compact Design

- Optional Machine Vision System for Real-Time Process Monitoring

- Flexible Software & Hardware Configuration for Personalized Production Needs

- Easy Operation with Open Control Software and Intuitive Interface