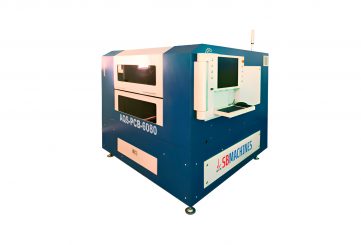

AQS-SE-6080 Laser cutting machine for precision 2D steel equipment

- Table size (mm): 600х800

- WT: 0~2.0±0.02 mm

- Materials: Precision stainless steel, carbide steel, etc. before or after surface treatment

- Source type: Fiber

- Option:

Scope of application

Laser micromachining of flat and curved instruments such as precision stainless steel and carbide steel before or after surface treatment

High finishing

- Cutting seam width: 15~30um

- High machining accuracy: ≤±10um

- Good incision quality: smooth incision & small heat-affected zone & few burrs

- Size refinement: minimum product size 20um

Strong adaptability

- Possess the ability of fine processing technology such as laser cutting, drilling and slotting of flat & curved instruments

- Various materials such as precision stainless steel, hard alloy steel, etc. can be machined before or after surface treatment

- Equipped with self-developed direct-drive mobile double-drive precision motion platform, granite platform, aluminum alloy & granite beam for selection

- Provide optional functions such as double station & visual positioning & automatic loading and unloading system & processing dynamic monitoring

- Equipped with self-developed long & short focal length sharp & flat fine laser cutting head

- Configure modular feed and dust ductwork

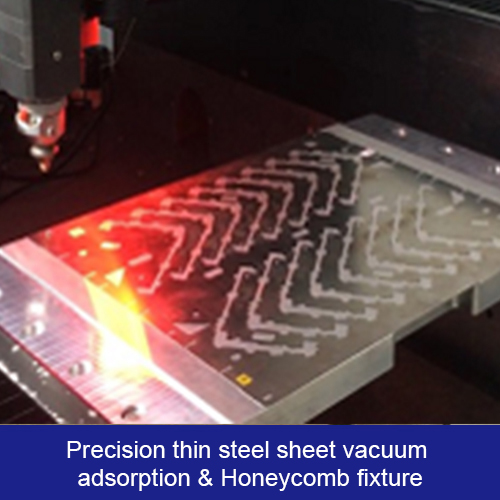

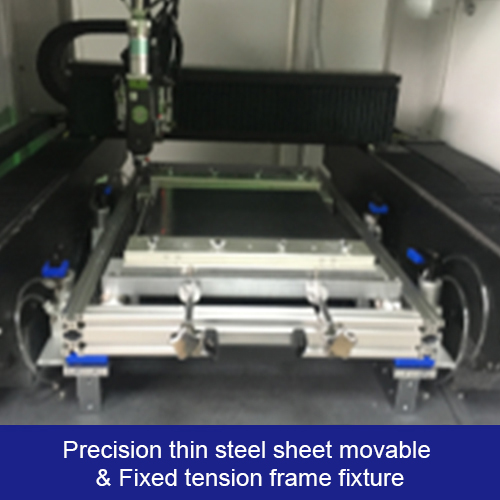

- Provide self-developed movable tension frame&fixed tension frame&vacuum adsorption&honeycomb board©ing jig and other fixture options

- Equipped with self-developed laser micromachining 2D & 2.5D & 3D CAM software system

Flexible design

- Follow the ergonomic design concept, exquisite and concise

- Flexible combination of software & hardware functions, support personalized function configuration & intelligent production management

- Support forward innovative design from component level to system level

- Open Control & Laser Micromachining Software System Easy Operation & Intuitive Interface

Technical certification

- THIS

- ISO9001

- IATF16949

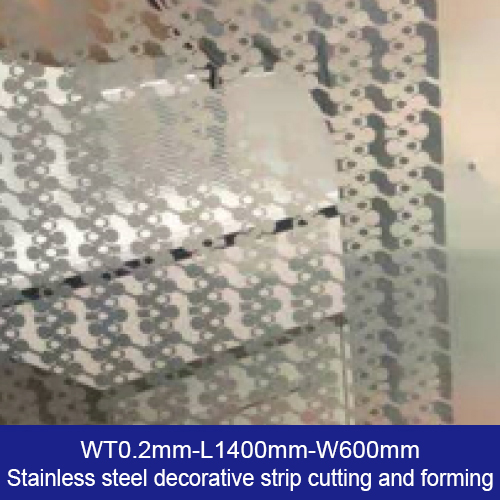

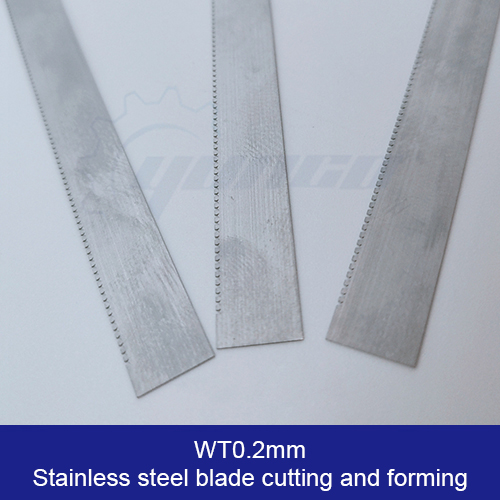

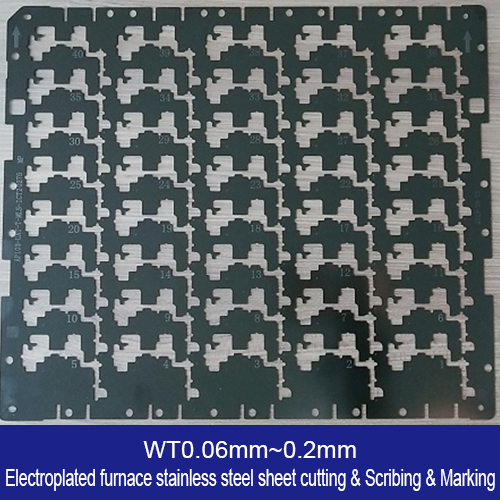

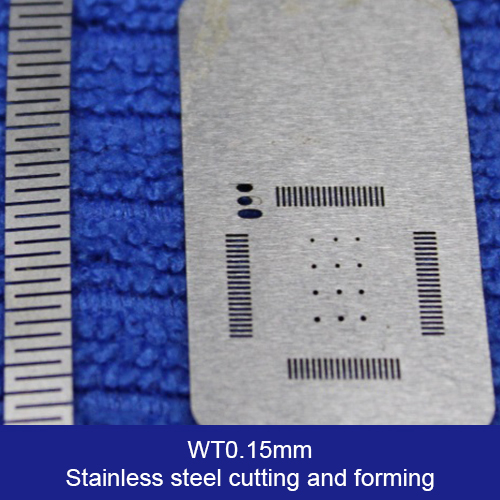

Sample display

Materials

-

Processing Materials:

- Precision stainless steel

- Carbide steel

- Materials can be processed both before and after surface treatment

-

Laser Specifications:

- Fiber-optic laser with wavelength 1030~1070±10nm

- Power Options: CW200W, 250W, 300W, 500W, 1000W, QCW150W

- Cutting Seam Width: 15~30μm

- Material Wall Thickness: 0~2.0±0.02 mm

Application

Scope of Use

Precision laser micromachining for:

- Stainless steel instruments

- Carbide steel instruments

- Semiconductor integrated circuit manufacturing

Processing Capabilities

- Cutting, drilling, and slotting with high precision

- Smooth incisions with minimal heat-affected zone and burr-free edges

- Minimum product size: 20μm

Industries Served

- Semiconductor industry

- Precision metalworking for high-performance steel equipment

Specifications

Performance and Efficiency

Maximum Operating Speeds:

- X, Y1, Y2 Axes: 1000mm/s

- Z Axis: 50mm/s

Positioning Accuracy:

- ±3μm (X, Y1, Y2)

- ±5μm (Z)

Repeatability:

- ±1μm (X, Y1, Y2)

- ±3μm (Z)

Advanced Features

- Double station and visual positioning options

- Automatic loading and unloading system with dynamic processing monitoring

- Self-developed sharp & flat fine laser cutting head with long and short focal length options

- Modular feed and dust removal system

- Optional fixtures: movable tension frame, fixed tension frame, vacuum adsorption, honeycomb board

Certified Quality

- ISO9001

- IATF16949

Design Excellence

- Ergonomic, compact, and modular design

- Self-developed 2D, 2.5D, and 3D CAM software for flexible production management

- Intuitive interface with customizable software and hardware configurations