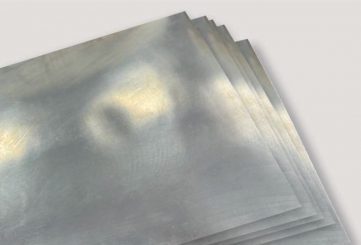

Kobalt-Krom Teller (CoCr Teller)

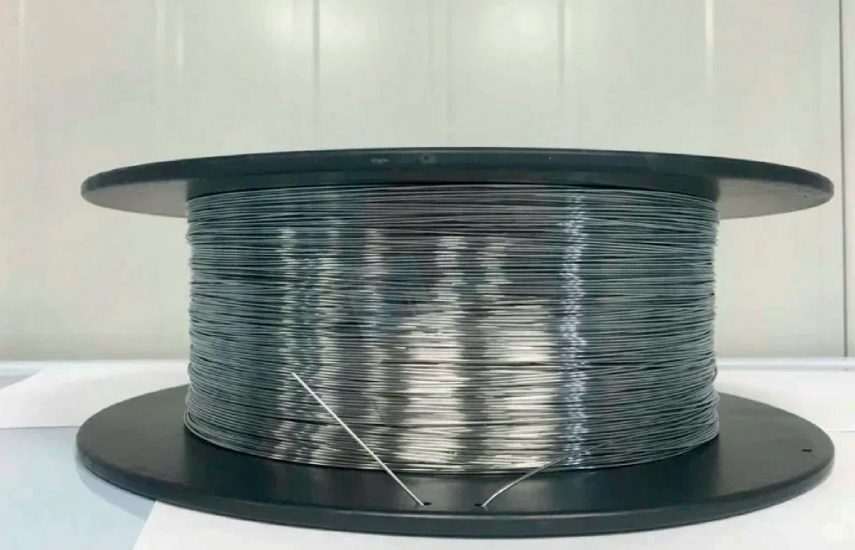

Cobalt-Chrome Wire: Flexible, High-Strength Strands for Precision Medical Solutions

Cobalt Chrome Wires Description:

Soğuk çekme yoluyla üretilen, 0,02 mm (20 mikron) ila 4 mm çaplarındaki katı kobalt-krom teller. Ra 0,1–0,5 µm'ye kadar cilalanmış L605 ve MP35N teller, özel özellikler sunar: L605 tokluk, MP35N ise korozyon direnci sağlar.

Cobalt Chrome Wires Key Features:

- Superior wear resistance for prolonged use (L605 excels here).

- High tensile strength (MP35N reaches up to 1400 MPa).

- Excellent biocompatibility with blood and tissue.

Cobalt Chrome Wires Certification and Standards:

- ASTM F90 (L605): For CoCrWNi wire in medical applications.

- ASTM F562 (MP35N): For CoCrNiMo wire.

- ISO 10993: Biocompatibility testing.

- ISO 15841 (orthodontics) and ISO 11070 (guidewires); manufacturer tolerances apply.

Neden Kobalt-Krom?

Kobalt-krom'un gücü, aşınma direnci ve biyouyumluluğu—L605 ve MP35N gibi sınıflarla geliştirilmiş ve titiz standartlarla desteklenmiştir—onu tıbbi yenilikler için en iyi tercih haline getirir. Belirli uygulamalar veya özel çözümlerle mi ilgileniyorsunuz? Daha fazla bilgi için bize ulaşın!

Cobalt-chrome (CoCr), an alloy of cobalt and chromium often enhanced with molybdenum, is prized for its exceptional strength, corrosion resistance, and biocompatibility. With tensile strength ranging from 800–1500 MPa and hardness of 300–550 HV, CoCr is a cornerstone in medical technology. Popular grades like L605 (Co-Cr-W-Ni) and MP35N (Co-Cr-Ni-Mo) elevate its performance

- Orthodontic Wires: L605 wires (0,3–0,8 mm Ø) deliver 2–5 N force for teeth alignment.

- Guidewires: MP35N wires (0,5–1 mm Ø, 100–300 cm long) navigate vascular systems.

- Surgical Sutures: Thin MP35N wires (0,1–0,5 mm Ø) secure tissues with up to 60 N strength.

- Diameter: 0,02–4 mm

- Weight: ~0,065 g/m (at 1 mm Ø, L605), ~0,066 g/m (MP35N)

- Tensile Strength: 1000–1200 MPa (L605), 1200–1400 MPa (MP35N)

- Elongation: 10–20%

- Surface Finish: Ra 0,1–0,5 µm