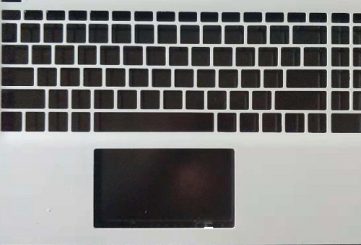

قطع وتثقيب وتشكيل غلاف الهاتف المحمول (الكمبيوتر الشخصي + الألياف الزجاجية)

Mobile Phone (PC+Glass Fiber) Shell Cutting, Punching and Forming – Precision Laser Solution

This is a high-precision laser system for cutting, punching, and forming PC+glass fiber shells, ideal for consumer electronics, delivering exceptional durability and detail.

The Mobile Phone (PC+Glass Fiber) Shell Cutting, Punching and Forming system from AQ-Laser is an advanced laser processing solution designed for high-precision micromachining of polycarbonate (PC) and glass fiber composite shells used in mobile phone manufacturing. Tailored for industries such as consumer electronics, telecommunications, and automotive, this system delivers clean, burr-free cuts, precise punching, and intricate forming with minimal thermal impact. Optimized for the strength and lightweight properties of PC+glass fiber composites, it enables complex designs critical for durable, high-quality mobile device casings. Equipped with automated features like precise positioning, focusing, and optional conveyor systems, it ensures efficient, high-quality production for sophisticated applications.

الميزات الرئيسية:

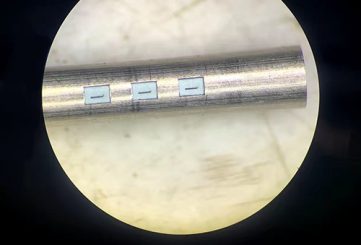

- High-Precision Processing: Achieves cutting and punching accuracy of ≤±10μm for intricate, burr-free designs.

- Material Optimization: Processes PC+glass fiber composites with high strength and lightweight properties.

- Low Thermal Impact: Advanced CO2 laser technology minimizes heat-affected zones, preserving material integrity.

- Automated Efficiency: Includes automatic positioning, focusing, and optional conveyor systems for streamlined production.

- CleanCut Technology: Ensures carbonization-free edges, enhancing technical cleanliness and aesthetic quality.

- Durability: Supports PC+glass fiber’s excellent impact resistance and longevity for robust components.

Certification and Standards:

Certified to ISO9001 standards, ensuring consistent quality for consumer electronics and telecommunications applications. Compliant with CE marking and RoHS directives for safety and environmental sustainability.

Primary Material:

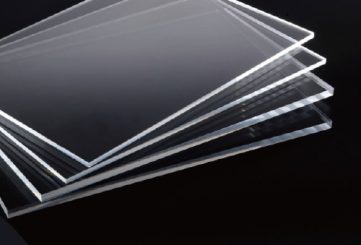

- Polycarbonate (PC) + glass fiber composite – known for its durability, impact resistance, and lightweight properties.

Compatible Materials:

- Acrylic

- Epoxy resin

- Rubber

- Other non-metallic materials

- High-precision cutting, punching, and forming of PC+glass fiber shells for mobile phone casings.

- Intricate pattern cutting and engraving for consumer electronics and telecommunications devices.

- Processing of PC+glass fiber composites for automotive components and durable enclosures.

- Suitable for custom designs in consumer electronics and protective device casings.

- Laser Type: High-performance CO2 laser

- Processing Accuracy: ≤±10μm

- Cutting Seam Width: 15–30μm

- Material Compatibility: Polycarbonate (PC) and glass fiber composites

- Processing Capabilities: Cutting, punching, forming, and engraving

- Automation: Automatic positioning, focusing, and optional conveyor systems

- Supported Formats: Gerber, DXF, DWG, SVG, and other 2D CAD formats