Tubo de acero inoxidable de 0,15 mm

Tubo de acero inoxidable de 0,15 mm – tubo de ultra precisión para aplicaciones micromédicas

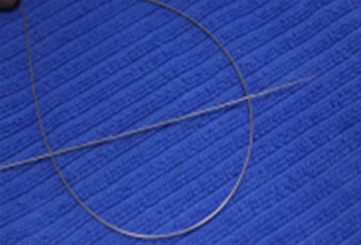

El tubo de acero inoxidable de 0,15 mm es un tubo ultrafino de alta precisión diseñado para sistemas de microcatéteres y endoscópicos. Fabricado con acero inoxidable SUS304 de grado médico, este tubo ofrece resistencia, flexibilidad y biocompatibilidad excepcionales, lo que lo hace ideal para procedimientos mínimamente invasivos que requieren conductos precisos y duraderos. Producido mediante micromecanizado láser avanzado, garantiza superficies sin rebabas y dimensiones exactas, facilitando una integración perfecta en dispositivos médicos mientras mantiene la resistencia a la corrosión y la esterilidad.

Características principales:

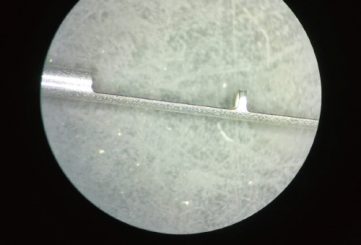

- Precisión ultraalta: Logra anchos de costura de corte de 15–30 μm y precisión de ≤±10 μm para superficies lisas sin rebabas.

- Durabilidad superior: Ofrece alta resistencia a la tracción y resistencia a la corrosión para un rendimiento confiable en entornos fisiológicos.

- Biocompatibilidad: Material hipoalergénico minimiza la reacción tisular, adecuado para contacto directo en aplicaciones sensibles.

- Flexibilidad: Soporta flexión variable sin torceduras, mejorando la maniobrabilidad en herramientas micromédicas.

- Integración eficiente: Compatible con varios sistemas de sujeción y métodos de corte para un ensamblaje rápido.

- Mantenimiento de la esterilidad: Acabado suave reduce los riesgos de contaminación y apoya los procesos de esterilización.

Certificados y estándares:

El tubo de acero inoxidable de 0,15 mm cumple con las normas de gestión de calidad ISO 13485 para dispositivos médicos y se adhiere a los requisitos de biocompatibilidad según ISO 10993.

Acero inoxidable SUS304:

Acero inoxidable SUS304 de grado médico (aleación austenítica de cromo-níquel), que ofrece excelente resistencia a la corrosión y propiedades mecánicas.

- Biocompatibilidad: Bajo riesgo de reacciones alérgicas o toxicidad, ideal para el contacto directo con tejidos en procedimientos médicos.

- Propiedades mecánicas: Alta resistencia a la tracción (aproximadamente 505 MPa) y elongación (hasta 40 %), proporcionando flexibilidad sin fragilidad.

- Acabado de superficie: Mecanizado por láser para bordes lisos sin rebabas, reduciendo el potencial de trauma tisular o contaminación.

- Estabilidad térmica: Mantiene la integridad en un amplio rango de temperaturas, adecuado para procesos de esterilización como el autoclavado.

Aleación de níquel-titanio:

El nitinol (NiTi), una aleación de níquel y titanio, es conocido por su superelasticidad y memoria de forma, lo que lo hace revolucionario en el ámbito médico. Con una resistencia a la tracción de hasta 1200 MPa y un módulo de elasticidad de 40–75 GPa, es ideal para condiciones exigentes.

Aleación de cobalto-cromo:

Cobalto-cromo (CoCr), una aleación de cobalto y cromo, a menudo mejorada con molibdeno, es valorado por su excepcional resistencia, resistencia a la corrosión y biocompatibilidad Con una resistencia a la tracción de 800 a 1500 MPa y una dureza de 300 a 550 HV, el CoCr es una piedra angular en las tecnologías médicas Las aleaciones populares, como L605 (Co-Cr-W-Ni) y MP35N (Co-Cr-Ni-Mo), elevan su rendimiento

- Sistemas de microcatéteres: Facilita la navegación precisa en procedimientos vasculares o urológicos que requieren tubos ultrafinos.

- Sistemas endoscópicos: Soporta una articulación flexible en microendoscopios para intervenciones mínimamente invasivas.

- Integración de alambre guía: Parte integral de la construcción de sistemas de alambres guías variables con requisitos de alta precisión.

- Reparación de dispositivos médicos: Empleado en el mantenimiento o reemplazo de componentes de microtúbulos en sistemas de catéteres y endoscópicos.

- Diseños médicos especializados: Adaptables para dispositivos experimentales o personalizados que requieren flexibilidad avanzada en cardiología o neurología.

- Composición del material: acero inoxidable SUS304.

- Dimensiones: Diámetro: 0,15 mm.

- Ancho de la costura de corte: 15–30 μm.

- Precisión de mecanizado: ≤±10 μm.

- Proceso de fabricación: Micromecanizado láser avanzado con alimentación automática continua para un acabado suave sin rebabas.

- Compatibilidad de sujeción: pinzas tipo D, pinzas de la serie ER, mandriles de tres garras.

- Métodos de corte: Opciones de corte en seco o en húmedo.

- Embalaje: Esterilizado y empaquetado individualmente para mantener la integridad.

- Condiciones de almacenamiento: Almacenar en un ambiente seco y fresco para evitar la corrosión.