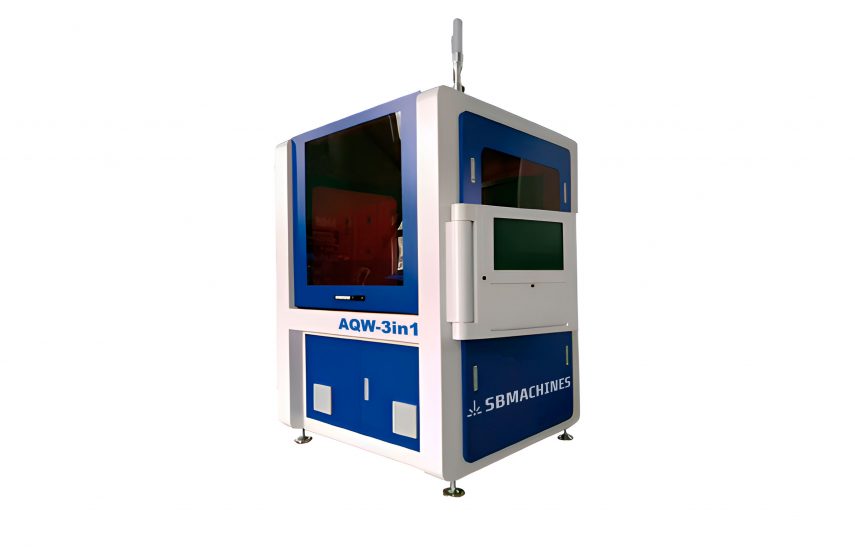

Máquina de soldadura láser AQW-3 en 1 para equipos médicos de precisión de metal

- Diámetro (mm): 0,1-7,5 y 1-16

- Longitud de procesamiento (mm): 300

- Tipo de fuente: Fibra

- Eje:

- Potencia: Diámetro 1-16 a QCW150W

Ámbito de aplicación

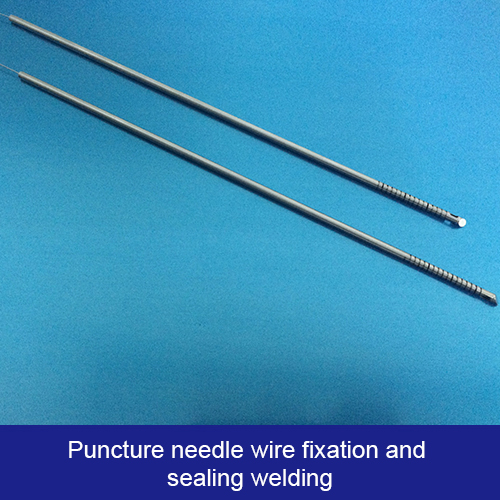

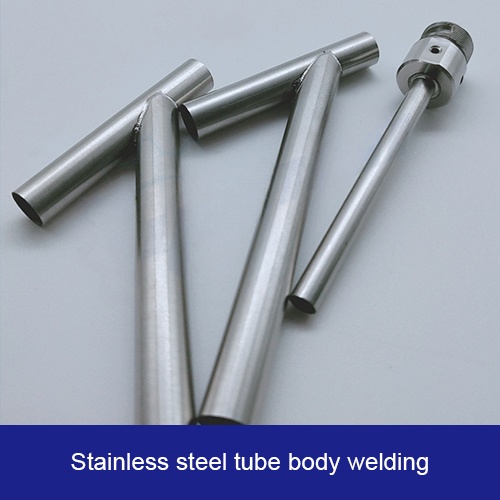

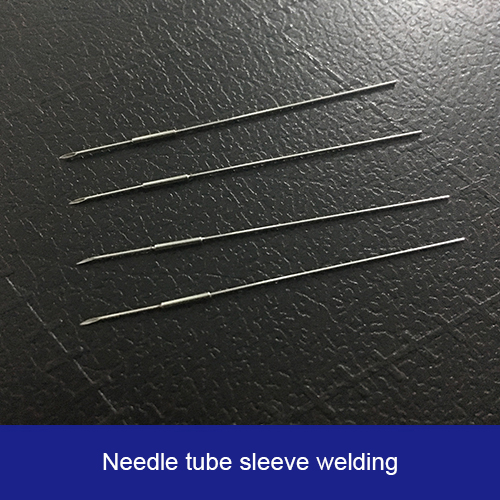

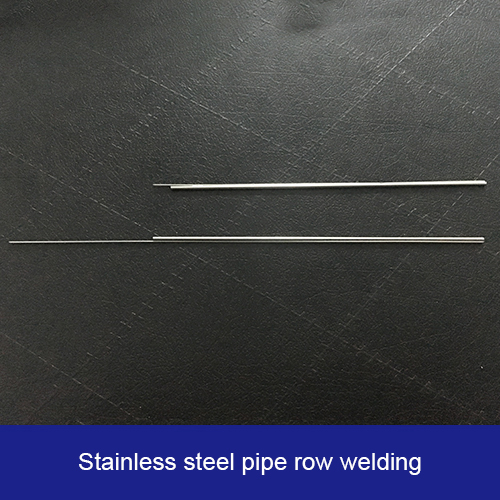

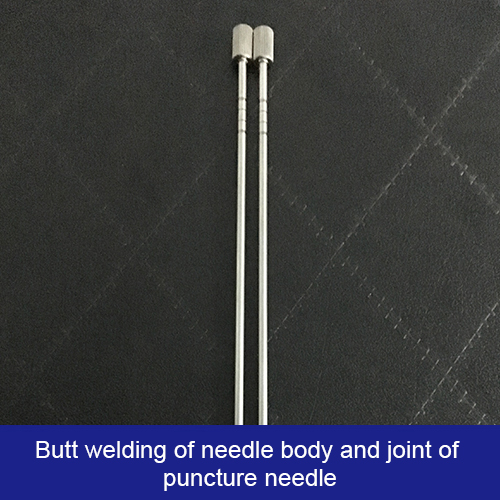

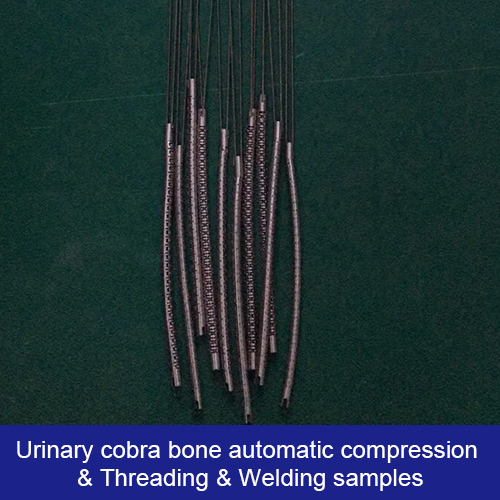

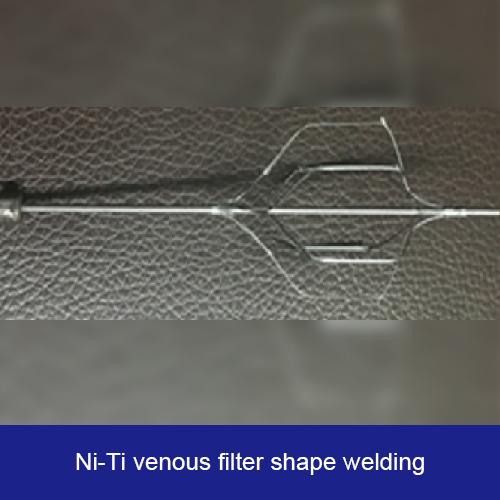

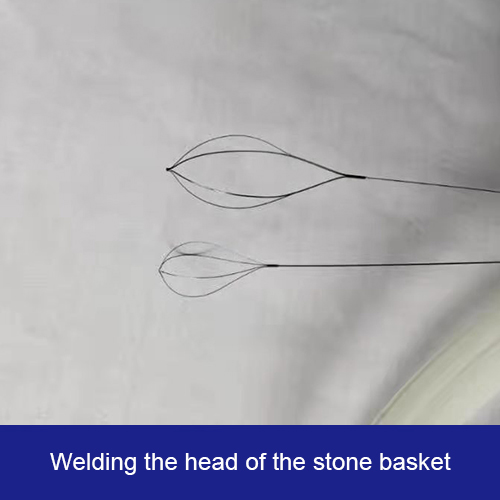

Cuchillo ultrasónico y tubo de aguja y aguja de punción y soporte y red de extracción de piedra azul y hueso de serpiente endoscópico, etc. Soldadura a tope, soldadura de manguito, soldadura en fila, procesamiento fino.

Soldadura de alta precisión

- Punto de soldadura pequeño: <Ø200um

- Alta precisión de soldadura: desviación radial de los instrumentos de tubo en movimiento rotatorio <10 um

- Buena calidad de soldadura: superficie de soldadura lisa, sin deformaciones evidentes, protuberancias, picaduras ni decoloración, buena estabilidad

- Alta eficiencia de procesamiento: se utiliza un control automático neumático para lograr una sujeción precisa de tubos de paredes delgadas, compatible con el sistema automático de carga y descarga de tubos.

Fuerte adaptabilidad

- Configurar el sistema de monitoreo y posicionamiento visual de precisión del proceso de mecanizado

- Puede realizar un procesamiento de soldadura fina en tubos de igual diámetro, tubos deformados, tubos semiacabados e instrumentos planos.

- Acero inoxidable mecanizable, níquel, titanio, platino, iridio, tántalo, base de cobalto, aluminio, cobre y otros materiales de aleación.

- Sistema de sujeción automática de tubos de precisión combinado diversificado

- Equipado con un sistema de software CAM 2D y 2.5D de micromecanizado láser de desarrollo propio

Diseño flexible

- Sigue el concepto de diseño ergonómico, exquisito y conciso.

- Configurar el sistema de visión artificial para lograr el posicionamiento automático y el monitoreo en línea en tiempo real del proceso de procesamiento dinámico del láser.

- Combinación flexible de funciones de software y hardware, admite configuración de funciones personalizadas y gestión de producción inteligente

- Apoyar el diseño innovador desde el nivel de componente hasta el nivel de sistema

- Sistema de software de micromecanizado láser y control abierto. Fácil operación e interfaz intuitiva.

Certificación técnica

- THIS

- ISO9001

- ISO13485

Pantalla de muestra

-

Materiales de procesamiento:

- Acero inoxidable

- Níquel titanio

- Platino Iridio

- Tantalio

- Aleaciones a base de cobalto

- Aluminio

- Cobre

-

Especificaciones del láser:

- Láser de fibra óptica

- Longitud de onda: 1030~1070 nm ± 10 nm

- Opciones de energía: 80W, 100W, 200W, 300W, QCW150W

- Energía máxima de un solo pulso: 50 J

-

Sistemas de sujeción:

- Sujeción automática neumática de precisión para tubos de paredes delgadas

- Sistema de sujeción personalizable para tuberías de mayor tamaño

Ámbito de uso

Soldadura fina de componentes de equipos médicos, incluyendo:

- Cuchillos ultrasónicos

- Tubos de aguja

- Agujas de punción

- Stents

- Redes de extracción de piedras

- Componentes endoscópicos "Snake Bone"

Capacidades de procesamiento

- Técnicas de soldadura de alta precisión:

- Soldadura a tope

- Soldadura de manguito

- Soldadura por hileras

- Punto de soldadura pequeño: Φ100~300 μm

- Descentramiento radial: <10 μm para instrumentos de tubo rotatorio

- Calidad de la soldadura:

- Superficie lisa

- Sin deformaciones, golpes, hoyos ni decoloración

Industrias atendidas

- Fabricación de equipos médicos intervencionistas

- Producción de instrumentos quirúrgicos y de diagnóstico

Rendimiento y eficiencia

- Velocidades máximas de funcionamiento:

- Ejes X, Y, Z: 50 mm/s

- Eje θ: 500 rpm

- Parámetros de soldadura:

- Profundidad: 0,1 ~ 1,0 mm

- Ancho de pulso: 0,1~20 ms

- Frecuencia: 1~20 Hz

Precisión y flexibilidad

- Precisión y repetibilidad:

- Precisión de posicionamiento: ±5 μm

- Repetibilidad: ±3 μm

- Rango de procesamiento:

- Procesamiento de tuberías: 0.1

7,0 mm y 1,016,0 mm (opcional, abrazaderas personalizables disponibles) - Procesamiento de planos: 300 mm × 300 mm

- Procesamiento de tuberías: 0.1

- Espesor de la pared: 0~1,0±0,02 mm

Funciones personalizables

- Sistema de posicionamiento y monitoreo visual de precisión para un mecanizado preciso

- Monitoreo en tiempo real con sistema de visión artificial

- Compatibilidad con formatos de archivos DXF y DWG

Calidad certificada

- ISO9001

- ISO13485

Diseño y usabilidad

- Diseño ergonómico y compacto

- Configuración flexible de software y hardware para una funcionalidad personalizada

- Interfaz intuitiva para una operación eficiente y una gestión inteligente de la producción