Formación de tubos con grapadora

- Corte suave: garantiza que no haya rebabas y bordes uniformes.

- Versatilidad del material: adecuado para diversas aleaciones y metales.

- Alta eficiencia: la alimentación automática continua reduce el tiempo de producción.

- Gran durabilidad: soporta rigurosos requisitos operativos.

Descripción del Producto

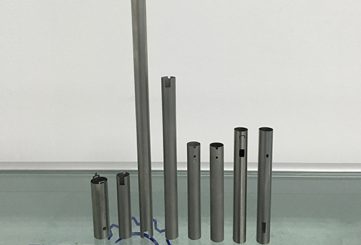

El Formación de tubos con grapadora Este componente está meticulosamente diseñado para aplicaciones médicas e industriales, ofreciendo precisión y durabilidad inigualables. Fabricado con una máquina de corte láser de cinco ejes de última generación, garantiza alta precisión y acabados suaves, lo que lo convierte en un elemento esencial en la producción de grapadoras quirúrgicas y otros dispositivos de precisión.

Características principales

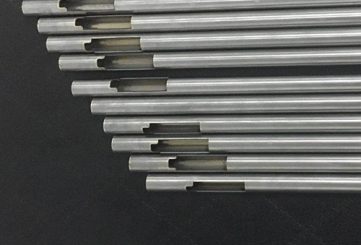

1. Alta precisión y bordes suaves:

- Ancho de costura de corte de 18–30 μm y precisión de mecanizado ≤±10 μm.

2. Diseño avanzado:

- Admite geometrías complejas, incluidas aperturas centrípetas y verticales.

3. Producción eficiente:

- Permite la alimentación automática continua y el corte láser preciso para un flujo de trabajo optimizado.

4. Compatibilidad versátil:

- Funciona con una amplia gama de materiales y sistemas de sujeción.

- Acero inoxidable 304 y 316L

- Aleaciones de Ni-Ti

- Aleación de cobalto y cromo L605

- Aluminio, magnesio y otros metales

El Formación de tubos con grapadora se utiliza en:

- Equipo quirúrgico:

- Esencial para grapadoras médicas y otros dispositivos quirúrgicos de precisión.

- Tubos médicos:

- Ideal para formar y dar forma a tubos de grado médico.

- Fabricación industrial:

- Aplicable en conjuntos mecánicos y electrónicos de alta precisión.