Materiales de alta precisión

11 artículosMateriales de alto rendimiento para fabricación de precisión

Nuestra avanzada tecnología de corte por láser se especializa en el procesamiento de materiales de alto rendimiento diseñados para industrias exigentes como dispositivos médicos, aeroespacial y semiconductoresEstos materiales, reconocidos por su resistencia, biocompatibilidad y precisión, son fundamentales en la producción de componentes de vanguardia como stents, catéteres, implantes y otros dispositivos complejos.

Ampliar materiales clave:

1. Nitinol (NiTi):

- Aleación con memoria de forma que combina níquel y titanio.

- Formularios: Disponible como tubos y barras, ideal para aplicaciones médicas como stents, guías e implantes.

- Propiedades clave: Excepcional elasticidad, resistencia a la corrosión y biocompatibilidad, lo que lo hace indispensable para dispositivos cardiovasculares y ortopédicos.

2. Aleaciones de cobalto-cromo (CoCr):

- L605: Aleación de alta resistencia y resistente a la corrosión utilizada en stents, herramientas quirúrgicas y piezas industriales de alto rendimiento.

- MP35N: Combina cobalto, cromo, níquel y molibdeno para una durabilidad, resistencia a la fatiga y biocompatibilidad inigualables.

- Aplicaciones: Perfecto para implantes médicos portantes, dispositivos dentales y componentes aeroespaciales.

3. Platino-iridio (PtIr):

- Aleación preciosa conocida por su radiopacidad y biocompatibilidad excepcional.

- Formularios: Se utiliza comúnmente en anillos y marcadores para catéteres y guías.

- Beneficios clave: Facilita la obtención de imágenes precisas y su colocación en procedimientos mínimamente invasivos.

¿Por qué estos materiales?

- Biocompatibilidad: Esencial para dispositivos médicos en contacto directo con el cuerpo humano.

- Fuerza y flexibilidad: Admite aplicaciones de alto rendimiento en condiciones extremas.

- Procesamiento de precisión: El corte por láser garantiza diseños intrincados con un mínimo desperdicio e impacto térmico.

Estos materiales forman la columna vertebral de la innovación en las industrias médica, aeroespacial y de alta tecnología, permitiendo a los fabricantes crear componentes que cumplen con los más altos estándares de confiabilidad, seguridad y rendimiento.

-

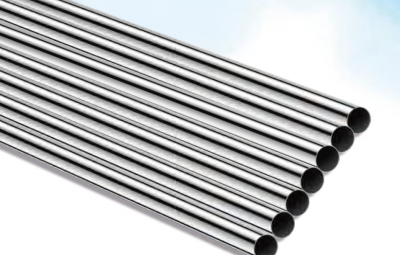

Tubos de cobalto-cromo (tubos CoCr)

Productos huecos de cobalto-cromo con estructura cilíndrica, fabricados por trefilado sin costura o extrusión Su tamaño varía desde microtubos (diámetro de 0,3 mm) hasta tamaños más grandes (hasta 25 mm), con un espesor de pared de 0,05–2 mm Debido a su alta resistencia a la corrosión y su fortaleza, se utilizan comúnmente aleaciones como L605 y MP35N -

Tubos de Nitinol (Tubo NiTi)

Estructuras cilíndricas huecas de Nitinol, fabricadas mediante extrusión o trefilado. Estos tubos tienen un diámetro que va desde 0,5 mm hasta 20 mm, con espesores de pared de 0,05 a 1 mm. -

Tubo de nitinol con núcleo de platino

Estructura compuesta que incluye un tubo exterior de nitinol (diámetro de 0,5 a 20 mm, espesor de pared de 0,05 a 1 mm), que encierra un núcleo de platino macizo o hueco (diámetro habitualmente entre el 10 % y el 50 % del diámetro interno del tubo). Fabricada mediante coextrusión o sellado, seguida de un tratamiento térmico para establecer la temperatura de transición del nitinol (30–37 °C). -

Marcadores de platino-iridio (marcadores PtIr)

Marcadores diminutos de platino-iridio, normalmente esferas, discos o cilindros cortos (de 0,1 a 3 mm de diámetro), fabricados mediante micromecanizado o corte por hilo. Estos marcadores aprovechan la densidad de la aleación y su radiopacidad para la visualización médica. -

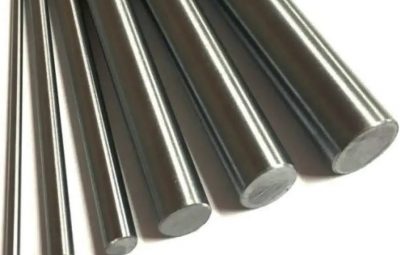

Varilla de cobalto-cromo (varilla CoCr)

Barras sólidas de cobalto-cromo, forjadas o prensadas, con un diámetro de 4 mm a 60 mm y una longitud de hasta 3 metros. L605 es adecuado para aplicaciones de alta carga, mientras que MP35N es excelente para entornos corrosivos. -

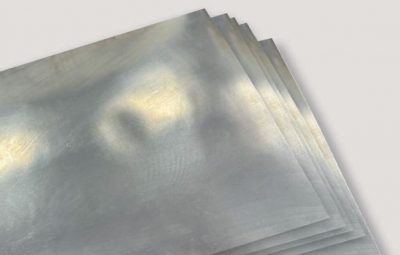

Láminas de cobalto-cromo (láminas CoCr)

Paneles planos de cobalto-cromo, laminados en caliente o forjados, con un espesor de 0,2 mm a 5 mm y dimensiones de hasta 400 × 400 mm L605 proporciona resistencia, mientras que MP35N mejora la resistencia a la corrosión para implantes personalizados -

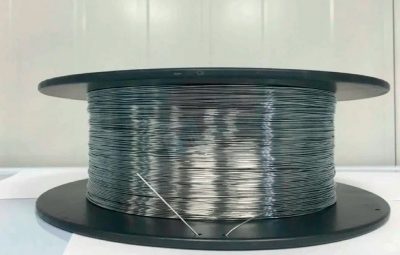

Alambre de cobalto-cromo (alambre CoCr)

Filamentos sólidos de cobalto-cromo, obtenidos por trefilado en frío, con un diámetro de 0,02 mm (20 µm) a 4 mm Pulidos hasta Ra 0,1–0,5 µm, los alambres L605 y MP35N poseen propiedades especiales — L605 para resistencia, MP35N para resistencia a la corrosión -

Varilla de nitinol con memoria de forma (varilla NiTi)

Varillas sólidas de nitinol, forjadas o prensadas, con un diámetro de 3 mm a 50 mm y una longitud de hasta 2 metros A menudo utilizadas como materia prima para procesamiento -

Lámina de nitinol con memoria de forma (lámina NiTi)

Paneles planos de nitinol, laminados en caliente hasta un espesor de 0,1–2 mm y dimensiones de hasta 300 × 300 mm Ideal para corte y conformación a medida -

Alambre de Nitinol (alambre NiTi) con memoria de forma

Hilos finos y sólidos de Nitinol, obtenidos mediante trefilado en frío, con diámetros desde 0,025 mm (25 µm) hasta 3 mm. El pulido superficial proporciona una suavidad de Ra 0,1–0,4 µm. -

Anillos de platino-iridio (anillos PtIr)

Las aleaciones de platino-iridio son materiales altamente especializados que combinan las propiedades superiores del platino con la mayor durabilidad y dureza del iridio.