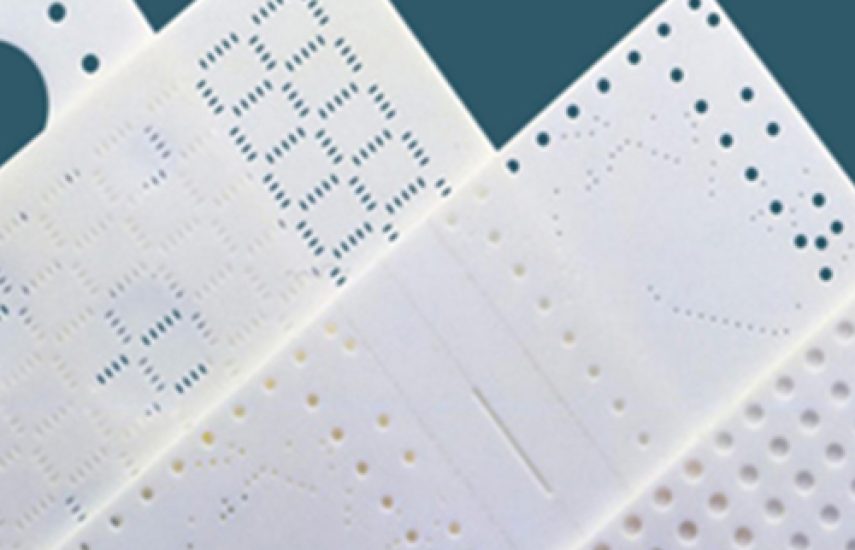

Corte y conformado de sustratos cerámicos

- High Adaptability: Compatible with various PCB materials.

- Diseño ergonómico: posicionamiento visual y monitoreo dinámico.

- Personalizable: Admite configuraciones personalizadas y producción inteligente.

- Calidad Certificada: Cumple con las normas ISO9001 y IATF16949.

Descripción del Producto

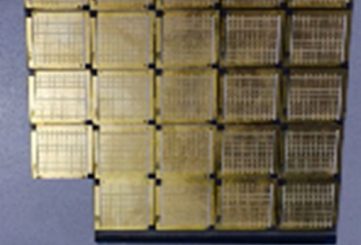

El Corte y conformado de sustratos cerámicos is a high-precision laser micromachining solution designed for creating intricate and durable cuts on ceramic substrates. Utilizing advanced fiber laser technology, this process ensures exceptional accuracy, smooth finishes, and burr-free edges. It is ideal for applications requiring precise and complex ceramic substrate processing.

Características principales:

- Alta precisión: Precisión de corte de ≤±10µm.

- Acabado liso: Smooth cuts with a seam width of 20~40µm and minimal heat-affected zone.

- Procesamiento eficiente: Sistema de doble accionamiento móvil con accionamiento directo para corte en una sola operación.

- Versatilidad del material: Compatible with ceramic substrates and other PCB materials.

- Tecnología avanzada: Fabricado mediante software CAM 2D y 2.5D.

-

Ceramic Substrate

-

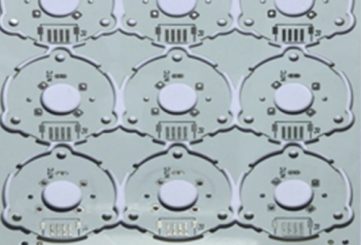

Aluminum Substrate

-

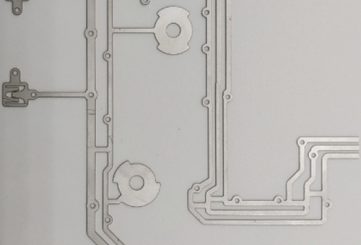

Copper Substrate

El Corte y conformado de sustratos cerámicos Se utiliza ampliamente en la industria para:

-

Fabricación de PCB

-

Electrónica de precisión

-

Aplicaciones industriales

-

Aplicaciones de tratamiento de superficies