AQT-SE Beş eksenli cerrahi ekipmanlar için lazer kesim makinesi

AQT-SE Beş eksenli cerrahi ekipmanlar için lazer kesim makinesi – Üstün hassasiyetli boru işleme

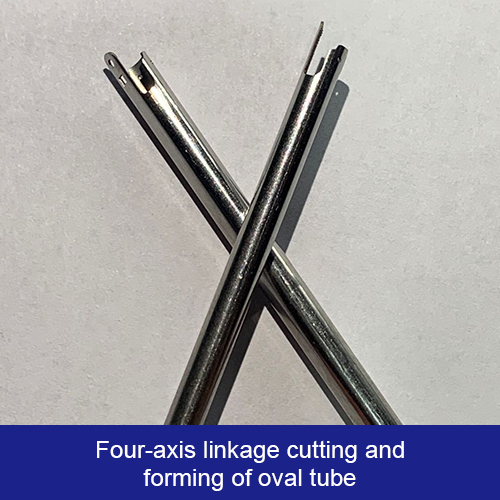

AQT-SE Beş eksenli lazer kesim makinesi, cerrahi ekipman bileşenlerini eşsiz hassasiyet ve yüzey kalitesiyle üretmek için özel olarak tasarlanmıştır. Beş eksenli hareket kontrolü sayesinde bu makine, endoskoplar, staplerler, yumuşak matkaplar ve burun matkapları gibi karmaşık ince duvarlı tüplerin ve küçük cerrahi parçaların işlenmesinde mükemmeldir. Gelişmiş lazer kaynağı ve sağlam yapısı minimum termal bozulma, yüksek tekrarlanabilirlik ve temiz kenar kalitesi sağlar.

Çeşitli metaller ve cerrahi sınıf alaşımları işleyebilen AQT-SE, yüksek hacimli ve yüksek hassasiyetli üretim için idealdir. Entegre otomasyon ve kontrol sistemleri, hızlı ayar değişiklikleri ve hassas işlemler sağlayarak atıkları en aza indirir ve verimi en üst düzeye çıkarır.

Uygulama kapsamı

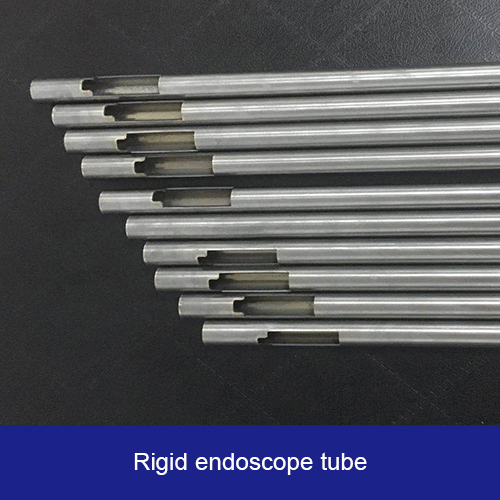

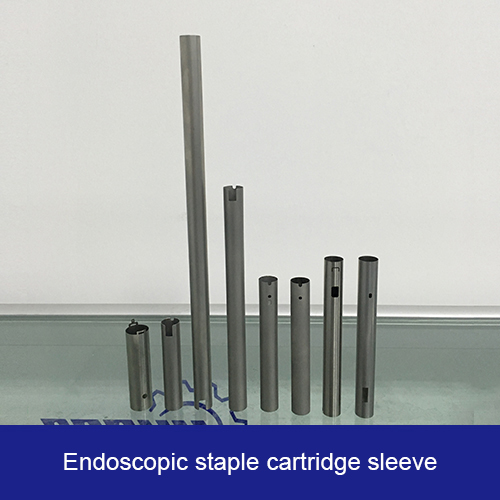

Bu makine, rijit endoskoplar, ultrasonik bıçaklar, staplerler, yumuşak matkaplar, ponksiyon iğneleri, burun matkapları ve hem geometrik karmaşıklık hem de sıkı yüzey kalitesi gerektiren diğer küçük cerrahi alet bileşenlerinin üretimi için uygundur. Tıbbi aletlerde tipik olan tüp boyutlarını ve cerrahi standartlara uygun malzemeleri destekler.

Avantajlar:

Sabit kalite ile yüksek verim, hurda ve duruş sürelerini azaltır.

- Kavisli ve spiral geometrilerin hassas işlenmesi; çok eksenli kontrol, iş parçasını yeniden konumlandırmadan farklı açılarda kesim yapılmasına olanak tanır.

- Temiz, çapaksız kesim; ek finisaj ihtiyacını azaltır veya tamamen ortadan kaldırır.

- Sabit kalite ile yüksek verim, hurda ve duruş sürelerini azaltır.

Yüksek bitirme

AQT-SE, hassas lazer optiği, kararlı ışın iletimi ve soğutma / ısı yönetim sistemi sayesinde son derece pürüzsüz yüzeyler sağlar. Lazer parametrelerinin sıkı kontrolü, minimum ısıl etki bölgeleri oluşturarak ince kenar tanımı ve minimum renk değişimi veya deformasyon garanti eder.

- İç ve dış tüp yüzeylerinde neredeyse ayna benzeri yüzey kalitesi.

- Parça boyunca minimum koniklik ve kesim genişliği varyasyonu.

- Azaltılmış son işlem ihtiyacı (parlatma / elektropolaj / mekanik finisaj).

Güçlü uyum yeteneği

AQT-SE, cerrahi aletlerde kullanılan çeşitli paslanmaz çelikler, titanyum alaşımları, NiTi (nitinol), kobalt-krom ve diğer biyouyumlu metaller dahil olmak üzere geniş bir malzeme yelpazesine iyi uyum sağlar. Kontrolleri, küçük tüpler, keskin bükümler ve hassas özellikler için kesim parametrelerinin doğruluktan ödün vermeden ayarlanmasına olanak tanır.

Ayrıca çeşitli tüp çapları ve duvar kalınlıklarını da işleyebilir, bu da onu hem yüksek derecede uzmanlaşmış küçük parti aletler hem de ölçekli üretim için uygun hale getirir. İster içi boş tüpler, ister kavisli endoskopik parçalar veya katı bağlantı parçaları olsun, beş eksenli işlemenin esnekliği farklı karmaşıklık seviyelerindeki üretimlere uyum sağlar.

Esnek tasarım

AQT-SE’nin mekanik ve yazılım mimarisi uyumluluk için tasarlanmıştır. Farklı tüp geometrileri için modüler fikstürler ve takımlar, otomatik yükleme ve boşaltma ile karmaşık açılı kesimler için programlanabilir kafa yolları sağlar.

- Farklı dış çaplar ve boru profilleri için modüler fikstürler.

- Konfigüre edilebilir kesme kafası açıları ve mekanik yeniden konumlandırma olmadan çok eksenli yörüngeler.

- Otomatik besleme sistemleri ve kalite izleme ile kolay entegrasyon.

Teknik sertifikasyon

AQT-SE, ilgili ISO standartlarına (ör. ISO 13485) ve CE sertifikasına uygunluk dahil olmak üzere tıbbi cihaz üretim standartlarını karşılayacak şekilde tasarlanmıştır. Güvenlik, lazer emisyon kontrolü, temizlik ve izlenebilirlik için tüm sistemler entegre edilmiştir. Bileşenler, biyouyumluluk, tekrarlanabilirlik ve belgelenmiş süreç kontrolünü sağlamak için doğrulanmıştır.

Örnek ekran

İşleme Malzemeleri:

- 304 Stainless Steel

- Biyouyumluluk: Alerjik reaksiyonlar veya toksisite riski düşük, tıbbi prosedürlerde doğrudan doku teması için idealdir.

- Mekanik özellikler: Yüksek çekme dayanımı (yaklaşık 505 MPa) ve uzama (yüzde 40’a kadar), kırılganlık olmadan esneklik sağlar.

- Yüzey kaplaması: Pürüzsüz, çapaksız kenarlar için lazerle işlenmiş, doku travması veya kontaminasyon potansiyelini azaltır.

- Termal stabilite: Geniş bir sıcaklık aralığında bütünlüğünü korur, otoklavlama gibi sterilizasyon süreçleri için uygundur.

- 316L Stainless Steel

- Ni-Ti Alaşımları

- L605 Alloy

- Aluminum (Al), Copper (Gu), Lithium (Li), Magnesium (Mg), Iron (Fe)

- Aluminum Alloys Hafif, tıbbi sınıf malzemelerdir ve mükemmel korozyon direnci ile yüksek dayanıklılık/ağırlık oranı nedeniyle değerlidirler. Tipik olarak 200–600 MPa arasında değişen çekme dayanımı ve iyi süneklikleri sayesinde tıbbi ve endüstriyel uygulamalarda dayanıklılık sağlarlar. Biyouyumlulukları, implante edilemeyen cihazlar ve bileşenlerde kullanılmalarını destekler. Lazerle işlenerek pürüzsüz ve çapaksız yüzeyler elde edilir; bu da kontaminasyon risklerini en aza indirir ve sterilizasyon süreçleriyle uyumluluğu garanti eder.

- Magnezyum— hafif (1,74 g/cm³) ve biyobozunur bir metal olup, geçici tıbbi implantlar (stentler ve ortopedik vidalar gibi) için idealdir. WE43 veya JDBM gibi alaşımlar, çekme dayanımı (200–420 MPa) ve kontrollü bozunma (6–24 ay) sunar, güvenle toksik olmayan yan ürünlere (Mg²⁺ iyonları) çözünür. Biyouyumluluğu (ISO 10993) ve doku rejenerasyonunu destekleme yeteneği, magnezyumu kardiyovasküler ve kemik onarımı uygulamaları için uygun hale getirir. Magnezyumun elastik modülü kemiğe oldukça yakındır, bu da ortopedik kullanımlarda gerilme kalkanı etkisini en aza indirir.

- Lityum (Li): Hafif ve yüksek reaktif bir metal, implantlar için bataryalar gibi tıbbi cihazlarda kullanılır. Yüksek enerji yoğunluğu ve biyouyumluluğu, kalp pilleri ve nörostimülatörleri beslemek için idealdir.

- Bakır (Cu): Tıbbi ekipmanlarda ve kaplamalarda kullanılan iletken ve antimikrobiyal bir metal. Mükemmel elektrik iletkenliği ve bakterilere karşı doğal direnci, cihazların işlevselliğini ve hijyenini artırır.

- Demir (Fe): Bazı cerrahi aletlerde ve yapısal bileşenlerde kullanılan güçlü ve dayanıklı bir metal. Yüksek dayanıklılığı ve maliyet etkinliği, implant olmayan tıbbi aletler için uygun hale getirir.

Tıbbi sınıf SUS304 paslanmaz çelik (östenitik krom-nikel alaşımı), mükemmel korozyon direnci ve mekanik özellikler sunar.

316L paslanmaz çelik, tıbbi sınıf östenitik krom-nikel alaşımı olup, mükemmel korozyon direnci ve biyouyumluluğu ile bilinir. Yaklaşık 485–550 MPa çekme dayanımı ve ’a kadar uzama ile dayanıklılık ve kırılganlık olmadan esneklik sunar. Düşük karbon içeriği, kaynak kabiliyetini ve taneler arası korozyona karşı direnci artırır, bu da onu tıbbi implantlar ve aletler için ideal kılar. Lazerle işlenmiş pürüzsüz, çapaksız yüzeyler, hassas uygulamalarda doku tahrişini en aza indirir.

Nitinol (NiTi), nikel ve titanyum alaşımı olarak, süperelastikliği ve şekil hafızasıyla tıp alanında devrim yaratmıştır. 1200 MPa'ya kadar çekme dayanımı ve 40–75 GPa elastikiyet modülü ile zorlu koşullar için mükemmel bir tercihtir.

Kobalt-krom alaşımları (L605), olağanüstü dayanıklılığı, korozyon direnci ve biyouyumluluğu ile değerli tıbbi sınıf malzemelerdir. 800–1500 MPa arasında değişen çekme dayanımı ve 300–550 HV sertlik ile zorlu tıbbi uygulamalarda dayanıklılık sağlar. İmplantlar ve cerrahi aletler için idealdir, minimum reaksiyonla doğrudan doku teması destekler. Lazerle işlenmiş yüzeyler, hassas prosedürlerde performansı artıran pürüzsüz, çapaksız kaplamalar sağlar.

Kelepçeleme sistemleri:

- Hassas D-Tipi pensler

- ER Serisi Pensler

- Üç Çeneli Aynalar

Lazer Özellikleri:

- Fiber Optik Lazer

- Dalga boyu: 1030~1070nm±10nm

- Güç seçenekleri: 200W, 250W, 300W, 500W, 1000W, QCW150W

Kullanım Kapsamı

- Endoskoplar:

- Sert endoskoplar

- Standart endoskoplar

- Cerrahi Aletler:

- Ultrasonik bıçaklar

- Cerrahi staplerler

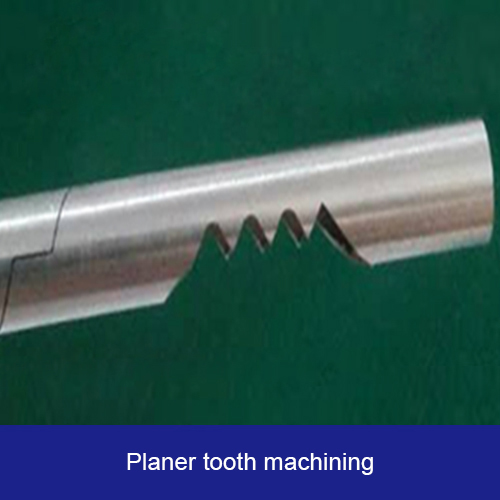

- Yumuşak matkaplar, planyalar, ponksiyon iğneleri, burun matkapları

İşleme Yetenekleri

- Lazerle kesme, delme ve oluk açma

- Eş çaplı ve redüksiyonlu borular için merkezcil, dikey ve bileşik açıklıklar

- Kesim dikiş genişliği: 18~30 μm

- Yüksek hassasiyet: ≤ ±10 μm

Hizmet Verilen Endüstriler

- Tıbbi ve endüstriyel cerrahi ekipman üretimi

Performans ve Verimlilik

- Maksimum Çalışma Hızları:

- X1-Axis: 300 mm/s

- X2-Axis: 100 mm/s

- Eixo Y: 50 mm/s

- Z Ekseni: 50 mm/s

- θ Ekseni: 600 devir/dakika

Çok yönlülük:

- İşleme duvar kalınlığı: 0~2.0 ± 0.02 mm

- Boru işleme aralığı:

- Φ0,3~Φ7,5 mm

- Φ1,0~Φ16,0 ± 0,02 mm

- Düz işleme aralığı: 200 mm x 100 mm

- Boru ham uzunluğu: <2,5 m (daha uzun boylar için özelleştirilebilir)

Esneklik ve özelleştirme

- Continuous Automatic Feeding Processing with Auto Loading/Unloading

- Compatible File Formats: DXF, DWG, STP, IGS

- Hassas mikroişleme için 2D, 2.5D ve 3D CAM yazılımlarını destekler

Sertifikalı Kalite

- ISO9001, ISO13485 Sertifikaları

Kullanıcı dostu tasarım

- Gerçek zamanlı izleme için opsiyonel makine görüş sistemi

- Ergonomic and Intuitive Interface for Easy Operation

- Adaptive Shape Tolerance for Thin-Walled Tubes