Ceramic Plate Slotting

Ceramic Plate Slotting – Precision Laser Machining for High-Performance Components

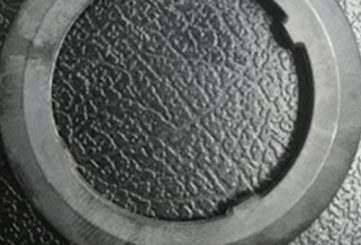

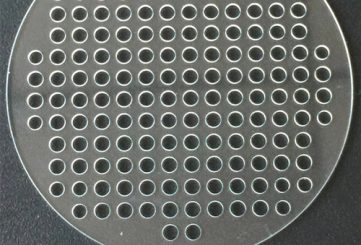

Ceramic Plate Slotting is a high-precision laser machining process designed to create precise slots and intricate patterns in ceramic plates for medical and electronic applications. Utilizing advanced CO2 laser technology, this process delivers clean, burr-free cuts with minimal thermal impact, ensuring the structural integrity of brittle ceramic materials. Crafted from high-performance ceramics such as alumina (Al2O3), aluminum nitride (AlN), and silicon nitride (Si3N4), the resulting components offer exceptional thermal conductivity, electrical insulation, and mechanical strength, making them ideal for microelectronic substrates, medical implants, and high-power electronics. The laser-slotted design enables complex geometries and precise slotting, optimizing performance in demanding environments. Tailored for high-precision applications, this process meets the rigorous standards of modern healthcare and electronics manufacturing.

Key Features:

- Ultra-Precise Slotting: Achieves slot accuracy of ≤±10 µm for intricate patterns and precise component designs.

- Burr-Free Edges: Produces clean, smooth slots for enhanced technical cleanliness and reliability.

- High Material Strength: Ceramics like Al2O3, AlN, and Si3N4 provide superior mechanical and thermal properties.

- Minimal Thermal Impact: CO2 laser technology minimizes heat-affected zones, preserving material integrity.

- Material Versatility: Compatible with alumina, aluminum nitride, and silicon nitride ceramic plates.

- Efficient Processing: Automated feeding system ensures high efficiency and consistent quality in batch production.

Certification and Standards:

The Ceramic Plate Slotting process is certified under ISO 9001, ensuring robust quality management across all production stages. It also complies with IATF 16949, guaranteeing exceptional quality control and traceability for critical applications in electronics and medical industries.

Primary Material – High-quality ceramics:

- Alumina

- Zirconia

- Silicon nitride, etc.

High-quality ceramics, such as alumina (Al2O3), aluminum nitride (AlN), and silicon nitride (Si3N4), offer exceptional thermal conductivity, electrical insulation, and mechanical strength. These materials are ideal for precision applications in medical implants, microelectronics, and high-power electronics, ensuring durability and performance in demanding environments.

Compatible Materials:

- Sapphire. Exceptional scratch resistance, high thermal stability, and transparency for optical and medical applications.

- Silicon. Excellent electrical properties, high thermal conductivity, and compatibility with microfabrication processes.

- Gallium arsenide. Superior electron mobility, high efficiency in LED and solar cells, and excellent high-frequency performance.

- Brittle materials. High hardness, thermal stability, and electrical insulation for precision components in demanding environments.

- Microelectronic Substrates: Produces precision-slotted ceramic plates for high-density electronic circuits.

- Medical Implants: Supports slotting of ceramic components for biocompatible implants and devices.

- High-Power Electronics: Used in substrates for power electronics and semiconductor applications.

- Optoelectronic Components: Facilitates slotting for LED packages and optical device mounts.

- Medical Device Manufacturing: Incorporated in the production of advanced ceramic components.

- Material: Ceramics (e.g., Alumina (Al2O3), Aluminum Nitride (AlN), Silicon Nitride (Si3N4))

- Thickness: 0.3–2.0 mm

- Slot Width: 15–30 µm

- Slotting Accuracy: ≤±10 µm

- Surface Roughness: Ra <0.2 µm

- Manufacturing Process: CO2 laser slotting with automated feeding

- Operating Temperature: -20°C to 500°C, suitable for high-temperature applications

- Degradation: Non-degradable, designed for long-term stability