High Precision Materials

11 itemsHigh-Performance Materials for Precision Manufacturing

Our advanced laser cutting technology specializes in processing high-performance materials tailored for demanding industries like medical devices, aerospace, and semiconductors. These materials—renowned for their strength, biocompatibility, and precision—are pivotal in the production of cutting-edge components such as stents, catheters, implants, and other intricate devices.

Expand Key Materials:

1. Nitinol (NiTi):

- Shape-memory alloy combining nickel and titanium.

- Forms: Available as tubes and bars, ideal for medical applications like stents, guidewires, and implants.

- Key Properties: Exceptional elasticity, corrosion resistance, and biocompatibility, making it indispensable for cardiovascular and orthopedic devices.

2. Cobalt-Chromium Alloys (CoCr):

- L605: High-strength, corrosion-resistant alloy used in stents, surgical tools, and high-performance industrial parts.

- MP35N: Combines cobalt, chromium, nickel, and molybdenum for unmatched durability, fatigue resistance, and biocompatibility.

- Applications: Perfect for load-bearing medical implants, dental devices, and aerospace components.

3. Platinum-Iridium (PtIr):

- Precious alloy known for its radiopacity and exceptional biocompatibility.

- Forms: Commonly used in rings and markers for catheters and guidewires.

- Key Benefits: Facilitates precise imaging and placement in minimally invasive procedures.

Why These Materials?

- Biocompatibility: Essential for medical devices in direct contact with the human body.

- Strength and Flexibility: Supports high-performance applications under extreme conditions.

- Precision Processing: Laser cutting ensures intricate designs with minimal waste and thermal impact.

These materials form the backbone of innovation across medical, aerospace, and high-tech industries, enabling manufacturers to create components that meet the highest standards of reliability, safety, and performance.

-

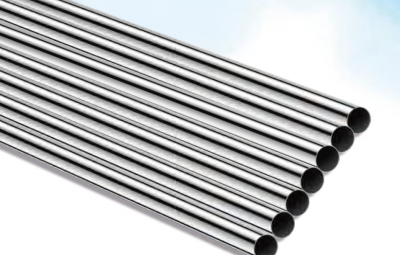

Cobalt-Chromium Tubes (CoCr Tube)

Hollow cobalt-chrome cylinders crafted through seamless drawing or extrusion, ranging from micro-tubes (0,3 mm diameter) to larger sizes (up to 25 mm), with wall thicknesses of 0,05–2 mm. Grades like L605 and MP35N are commonly used for their enhanced corrosion resistance and strength. -

Nitinol Tubes (NiTi Tube)

Hollow cylindrical structures made from nitinol, crafted through extrusion or drawing. These tubes range from small (0,5 mm) to larger diameters (20 mm) with wall thicknesses of 0,05–1 mm. -

Nitinol Tube with Platinum Core

A composite structure featuring an outer nitinol tube (diameter 0,5–20 mm, wall thickness 0,05–1 mm) encasing a solid or hollow platinum core (diameter typically 10–50% of the tube’s inner diameter). Crafted via co-extrusion or sleeving, followed by thermal treatment to set nitinol’s transition temperature (30–37°C). -

Platinum-Iridium Markers (PtIr Markers)

Tiny platinum-iridium markers, typically spheres, discs, or short cylinders (0,1–3 mm Ø), crafted via micro-machining or wire cutting. These markers exploit the alloy’s density and radiopacity for medical imaging. -

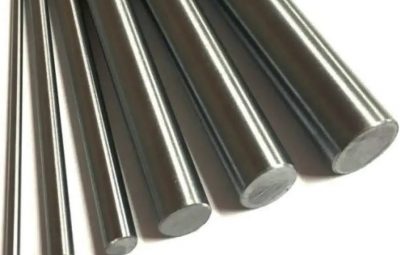

Cobalt-Chrome Bar (CoCr Bar)

Solid cobalt-chrome rods, forged or extruded, with diameters from 4 mm to 60 mm and lengths up to 3 meters. L605 suits high-stress applications, while MP35N excels in corrosive environments. -

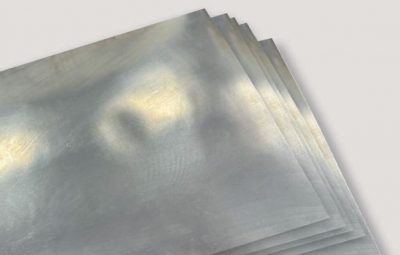

Cobalt-Chrome Sheet (CoCr Sheet)

Flat cobalt-chrome panels, hot-rolled or forged, with thicknesses from 0,2 mm to 5 mm and dimensions up to 400 × 400 mm. L605 provides toughness, while MP35N enhances corrosion resistance for custom implants. -

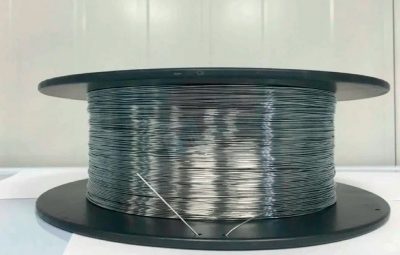

Cobalt-Chrome Wires (CoCr Wires)

Solid cobalt-chrome strands produced via cold drawing, with diameters from 0,02 mm (20 microns) to 4 mm. Polished to Ra 0,1–0,5 µm, L605 and MP35N wires offer tailored properties—L605 for toughness, MP35N for corrosion resistance. -

Nitinol Shape Memory Bar (NiTi Bar)

Solid nitinol rods, forged or extruded, with diameters from 3 mm to 50 mm and lengths reaching 2 meters. Often used as raw material for machining. -

Nitinol Shape Memory Sheet (NiTi Sheet)

Flat nitinol panels, hot-rolled to thicknesses of 0,1–2 mm and sizes up to 300 × 300 mm. Ideal for cutting and shaping into custom forms. -

Nitinol Wire (Niti Wire) with Shape Memory

Thin, solid nitinol strands produced via cold drawing, with diameters spanning 0,025 mm (25 microns) to 3 mm. Surface polishing achieves smoothness (Ra 0,1–0,4 µm). -

Platinum-Iridium rings (PtIr Rings)

Platinum-Iridium alloys are highly specialized materials that combine the superior properties of Platinum with the added durability and hardness of Iridium.