Tungsten Steel Sheet Cutting and Forming

Tungsten Steel Sheet Cutting and Forming – Precision Laser Solution

This is a high-precision laser system for cutting and forming tungsten steel sheets, ideal for medical and industrial applications, delivering exceptional durability.

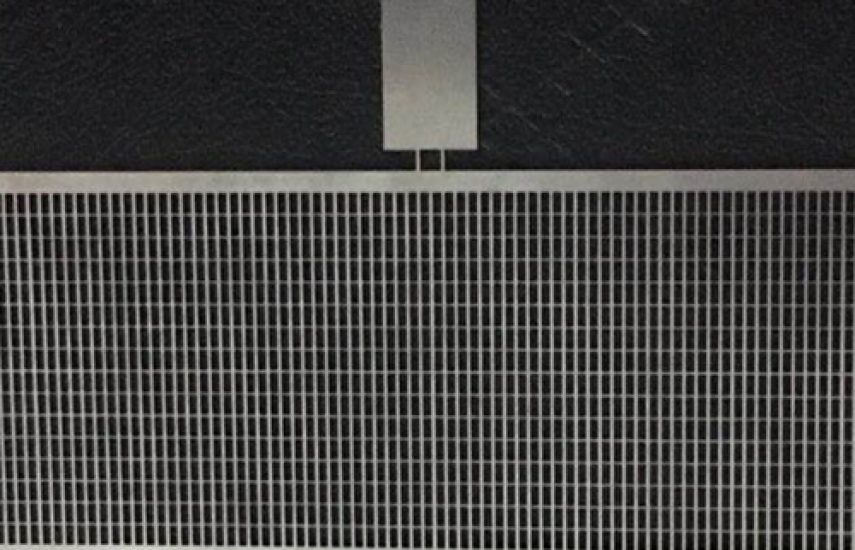

The Tungsten Steel Sheet Cutting and Forming system from AQ-Laser is an advanced laser processing solution designed for high-precision micromachining of tungsten steel sheets, known for their extreme hardness and high melting point. Tailored for industries such as medical device manufacturing, aerospace, and precision engineering, this system delivers clean, burr-free cuts and precise forming with minimal thermal impact. Optimized for the unique properties of tungsten steel, it enables intricate designs critical for applications like surgical tools and high-performance components. Equipped with automated features such as precise positioning and focusing, it ensures efficient, high-quality production for demanding applications.

Key Features:

- High-Precision Cutting: Achieves cutting accuracy of ≤±10μm and seam widths of 15–30μm for intricate, burr-free designs.

- Material Optimization: Processes tungsten steel sheets with exceptional hardness and high tensile strength.

- Low Thermal Impact: Advanced fiber laser technology minimizes heat-affected zones, preserving material integrity.

- Automated Efficiency: Includes automatic positioning, focusing, and feeding systems for streamlined production.

- CleanCut Technology: Ensures carbonization-free edges, enhancing technical cleanliness and reliability.

- High Durability: Supports tungsten steel’s superior wear and corrosion resistance for long-lasting components.

Certification and Standards:

Certified to ISO9001 and IATF16949 standards, ensuring consistent quality for medical and industrial applications. Compliant with CE marking and RoHS directives for safety and environmental sustainability.

Primary Material:

- Tungsten steel (high hardness and brittleness)

Tungsten steel is a high-performance alloy known for its extreme hardness, high melting point, and superior wear resistance. Ideal for precision components in medical devices, aerospace, and industrial applications, it offers excellent durability and strength in demanding environments.

Compatible Materials:

- Alumina

- Zirconia

- Silicon nitride

- Diamond

- Sapphire

- Other hard, brittle materials

- High-precision cutting and forming of tungsten steel sheets for surgical tools and medical devices.

- Contour cutting and marking for high-performance components in aerospace and industrial applications.

- Processing of tungsten steel for precision electrodes and high-durability mechanical parts.

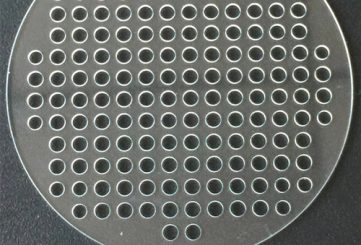

- Suitable for high-density interconnect (HDI) designs in advanced electronics and automotive applications.

- Laser Type: High-performance fiber laser

- Cutting Accuracy: ≤±10μm

- Cutting Seam Width: 15–30μm

- Material Compatibility: Tungsten steel sheets

- Processing Capabilities: Contour cutting, drilling, marking, and forming

- Automation: Automatic positioning, focusing, and feeding systems

- Supported Formats: Gerber, DXF, DWG, SVG, and other 2D CAD formats