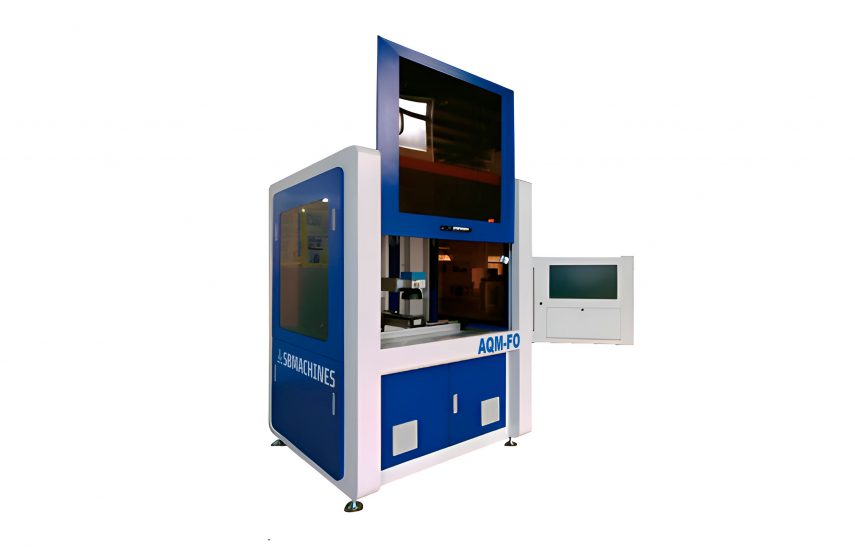

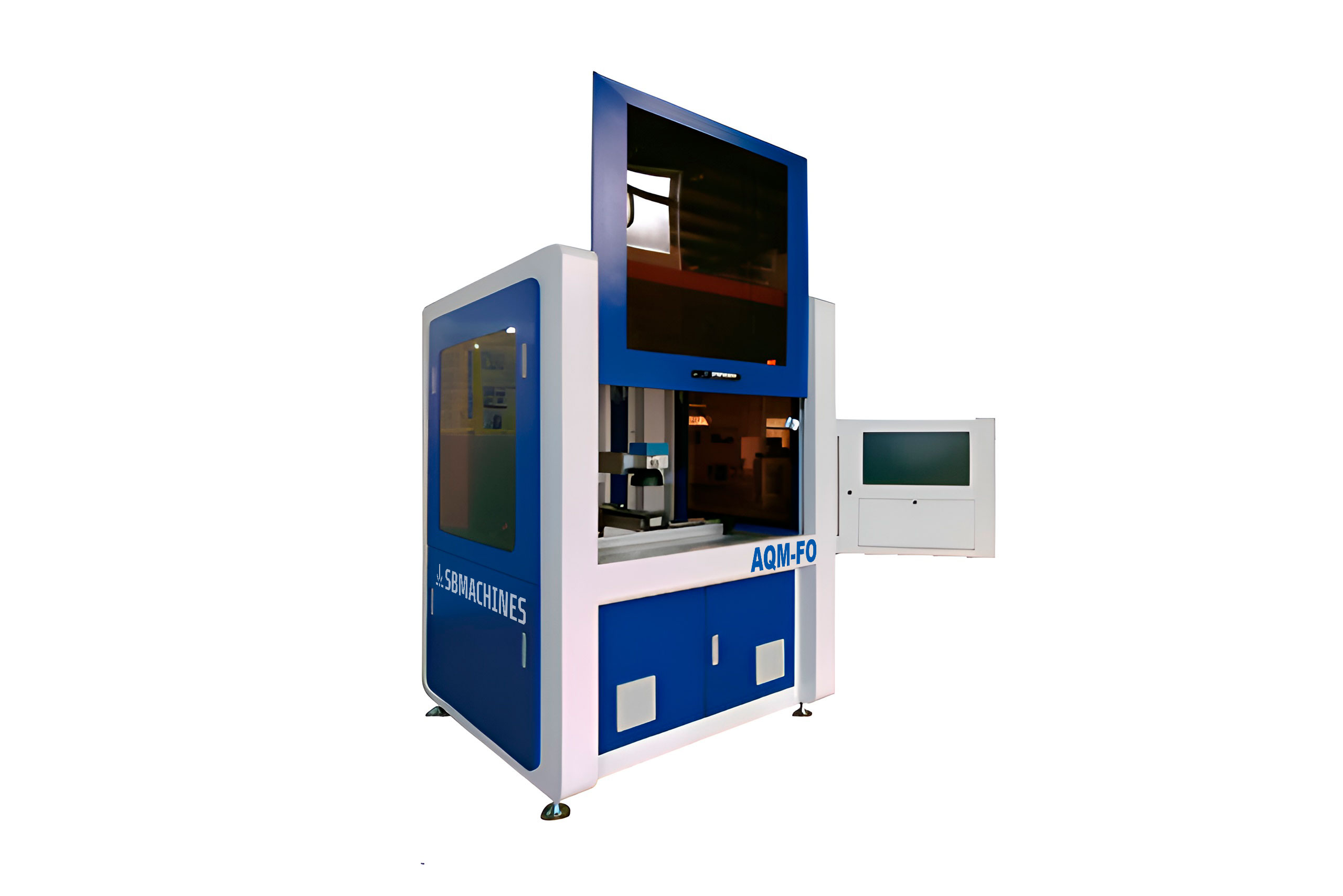

AQM-FO Fiber laser marking machine for medical equipment

AQM-FO Fiber Laser Marking Machine for Medical Equipment – Precision Marking & Engraving Platform

The AQM-FO is engineered for high-precision fiber laser marking, engraving, and fine processing of both metallic and non-metallic medical components. It delivers sharp, permanent markings while preserving the integrity of the part, making it ideal for UDI codes, component identification, traceability marks, logos, and micro-text on surgical devices.

With stable laser stability, fine beam control, and efficient scanning modules, the AQM-FO supports fast marking cycles, minimal heat impact, and reliable repeatability. Its design enables integration into clean production environments and compatibility with automated part handling systems.

Scope of application

This marking system is suited to medical devices and components such as implants, surgical instruments, catheter tubes, metallic and polymer parts. It supports marking on flat, curved, and tubular geometries, making it versatile across the medical device manufacturing line.

Advantages

- Permanent, high-contrast marks compatible with sterilization and cleaning

- Supports complex marking formats including UDI, DataMatrix, barcodes, serial numbers

- Non-contact, clean and chemical-free marking process

High finishing

The AQM-FO ensures that markings have crisp edges and minimal thermal distortion. Thanks to precise control of beam power, focus, and galvo scanning, it preserves surface smoothness and avoids substrate damage.

Advantages:

- Sharp, high-resolution lines and micro-text

- Minimal heat-affected zone, safeguarding material properties

- No discoloration, surface pitting or deformation

Strong adaptability

The machine can handle a wide array of medical-grade materials, including stainless steel, titanium, aluminum, various polymers, and coated surfaces. Its laser parameters (power, pulse width, scanning speed) can be dynamically tuned for each material to achieve optimal contrast and depth without compromising substrate.

Additionally, its marking optics and scan head configuration adapt to different shapes — flat surfaces, curved tubes, or angled geometries — making it flexible in part orientation and geometry handling.

Flexible design

Built with modularity in mind, the AQM-FO offers options to integrate machine vision for positioning, rotary attachments for tubular marking, and modular control units. You can customize hardware and software features to match your production layout and workflow.

Advantages:

- Optional vision system for alignment, inspection, and feedback

- Rotary modules for cylindrical or tubular marking

- Configurable software modules for script-based marking sequences

Technical certification

The AQM-FO is built to comply with industry and medical device manufacturing standards. It supports traceability, clean-room compatibility, and regulatory safety protocols. Its robust architecture ensures long-term stability, evidenced repeatability, and seamless integration into quality-controlled manufacturing environments.

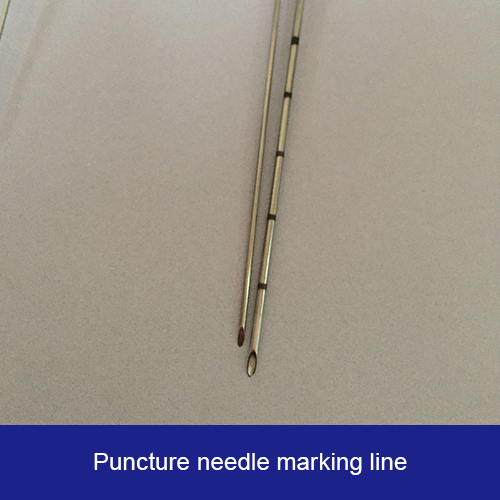

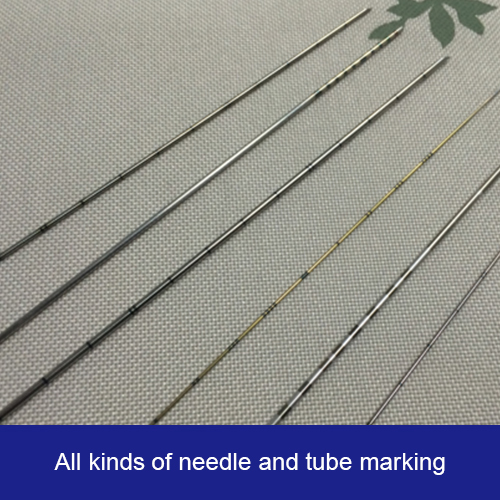

Sample display

Processing Materials:

- Stainless Steel (SUS)

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

- Nickel-Titanium (Ni-Ti)

- Titanium (Ti)

- Aluminum (Al)

- Copper (Cu)

- Plastics

Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

Titanium Alloys are medical-grade materials prized for their high strength-to-weight ratio, excellent corrosion resistance, and superior biocompatibility. With tensile strength ranging from 900–1200 MPa and good ductility, they provide durability and flexibility for demanding medical applications. Their bio-inert properties make them ideal for implants and instruments requiring direct tissue contact. Laser-machined surfaces ensure smooth, burr-free finishes, minimizing tissue irritation in sensitive procedures.

Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

Plastic is widely used in the manufacturing of medical devices due to its lightweight properties, cost-effectiveness, and design flexibility. Medical-grade plastics are biocompatible, resistant to corrosion and chemicals, and can withstand sterilization processes, making them safe for direct contact with patients. Their versatility allows the production of complex shapes and components with consistent quality, supporting innovation in surgical instruments, diagnostic equipment, and disposable medical products.

Laser Specifications:

- Fiber-Optic Laser

- Wavelength: 1064nm±10nm

- Power Options: 20W, 30W, 50W, 100W

Precision Clamping Systems:

- Pneumatic automatic clamping for thin-walled tubes

- Customizable clamping system for larger pipe sizes

Scope of Use

- Laser Marking, Engraving, and Fine Processing:

- Suitable for Metal and Non-Metal Materials

- Applicable Surfaces:

- Tubes

- Plane Instruments

- Intricate Designs on Small Surfaces

Processing Capabilities

- High-Precision Marking: Line Width 20~60 μm

- Radial Runout: For Rotary Tubular Instruments <10 μm

- Clear and Smooth Engraving with No Visible Deformation, Bumps, or Pits

- Pneumatically Controlled Automatic Clamping and Feeding System for High Efficiency

Industries Served

- Interventional Medical Equipment Manufacturing

- Precision Engineering for Surgical and Diagnostic Tools

Performance and Efficiency

- Maximum Operating Speeds:

- X, Y, Z Axes: 50 mm/s

- θ-Axis: 500 rpm

- Engraving Line Speed: ≤7000 mm/s

- Minimum Character Height: 0.2 mm

- Engraving Depth: Up to 0.4 mm (material dependent)

Precision and Flexibility

- Positioning Accuracy: ±5 μm

- Repeatability: ±3 μm

- Processing Range:

- Pipe Processing:

- 0.3~7.0 mm

- 1.0~16.0 mm (optional, customizable clamps available)

- Plane Processing: 300 mm × 300 mm

- Pipe Processing:

- Machining Wall Thickness: 0~1.0 ± 0.02 mm

Customizable Features

- Vision Positioning System for Precise Machining

- Real-Time Monitoring with Machine Vision System

- Compatibility with DXF and DWG File Formats

Certified Quality

- ISO9001

- ISO13485

Design and Usability

- Ergonomic and Compact Design

- Flexible Software and Hardware Configuration for Personalized Functionality

- Intuitive Interface for Easy Operation and Intelligent Production Management