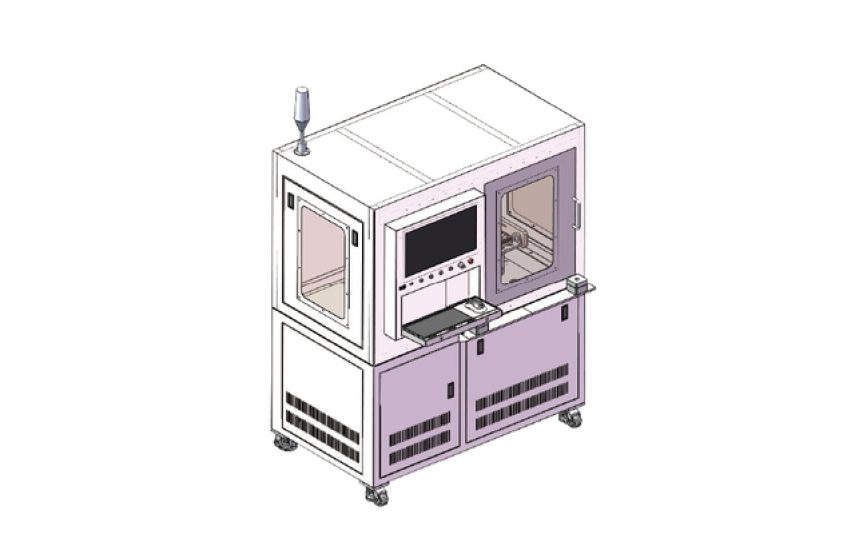

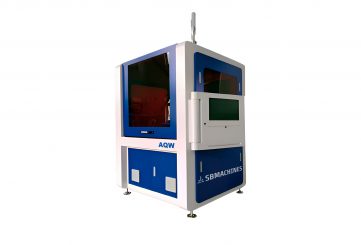

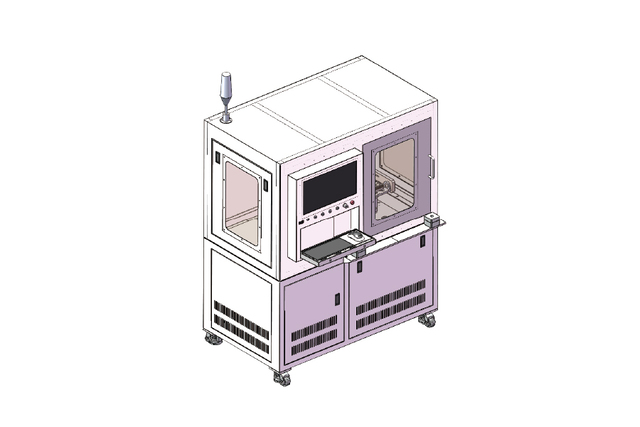

AQM-UV Precision UV laser marking machine

AQM-UV Precision UV Laser Marking Machine – Ultra-Fine, Cold-Process Marking Solution

The AQM-UV is a state-of-the-art ultraviolet laser marking system engineered for ultra-precise, low-heat processing of sensitive components. Designed to deliver micron-level accuracy without thermal damage, it is ideal for industries where marking clarity, minimal deformation, and traceability are paramount.

Combining advanced UV laser optics, high-speed scanning, and an intelligent control platform, the AQM-UV enables clean, consistent marking on a wide range of materials — from metals to polymers and glass — while preserving the integrity of the substrate.

Scope of application

The AQM-UV is suited for sectors requiring high-precision identification, traceability, and micro-marking, such as medical devices, microelectronics, semiconductors, optical components, and precision instruments. It excels especially where thermal effects must be minimized, such as on heat-sensitive substrates or when marking fine features.

Advantages include:

- Ability to mark extremely fine lines and characters with minimal heat-affected zones

- Compatibility with a broad range of materials, including plastics, ceramics, glass, and metals

- Reliable performance in cleanroom or laboratory environments

High finishing

The UV wavelength enables “cold” ablation — the laser photons break molecular bonds directly rather than relying on thermal evaporation — so marking is achieved with almost no heat transfer to surrounding areas. This results in crisp edges, no discoloration, and a near-zero risk of substrate damage.

Key benefits:

- Sharp, clear edges with minimal tapering or rounding

- Negligible thermal deformation, burning, or discoloration

- Stable marking quality over prolonged operation

Strong adaptability

The AQM-UV is engineered for versatility. Its control and optical modules allow users to tune parameters (pulse energy, frequency, scanning speed) to match the specific material and marking requirement. This flexibility supports a wide processing window, from ultra-fine microtext to deeper contrast marking on more robust substrates.

Additionally, the system’s motion and optical alignment can accommodate varying surface heights and geometries, making it suitable for both flat and curved parts, as well as irregular shapes.

Flexible design

The AQM-UV features a modular, compact architecture, facilitating integration into existing production lines or installation in constrained laboratory environments. Its optical path, cooling modules, and control electronics are arranged for easy access and maintenance.

Design advantages include:

- Modular and compact structure for flexible placement

- Easy access for servicing and component replacement

- Support for expansion with optional modules (rotary axes, vision systems, etc.)

Technical certification

The AQM-UV is built to meet industry standards for precision optical and laser equipment, ensuring compliance with applicable safety, electromagnetic, and quality certifications for deployment in regulated sectors such as medical, electronics, and aerospace.

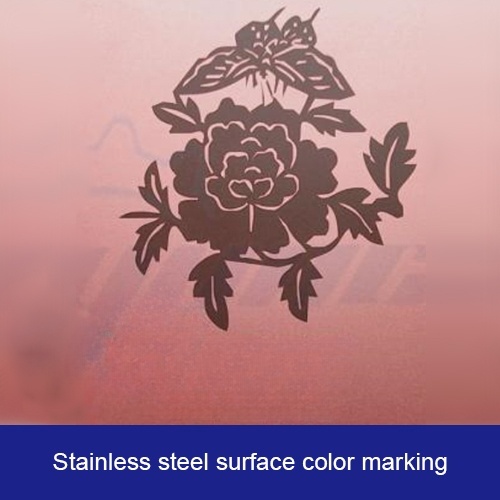

Sample display

Processing Materials:

- Stainless Steel

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

- Aluminum Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

- Copper A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

- Titanium alloys:

Titanium Alloys are medical-grade materials prized for their high strength-to-weight ratio, excellent corrosion resistance, and superior biocompatibility. With tensile strength ranging from 900–1200 MPa and good ductility, they provide durability and flexibility for demanding medical applications. Their bio-inert properties make them ideal for implants and instruments requiring direct tissue contact. Laser-machined surfaces ensure smooth, burr-free finishes, minimizing tissue irritation in sensitive procedures.

- Ceramic:

A biocompatible, wear-resistant material used in orthopedic and dental implants. Its hardness, corrosion resistance, and bioinert properties ensure long-term stability and tissue compatibility.

- Plastics (including Teflon and PTFE)

Laser Specifications:

- UV Laser

- Wavelength: 355±10nm

- Power Options: 3W, 5W, 10W

Precision Clamping Systems:

- Tube Clamps (customizable for larger pipes)

- Five-Axis Four-Linkage Precision Motion Platform

- Clamping and Positioning Jigs

Scope of Use

- Laser Marking and Engraving:

- 3C Consumer Goods

- Daily Hardware

- Electronic Equipment

- Applicable Surfaces:

- Tubes

- Flat Surfaces

- Regular Surface Instruments

Processing Capabilities

- High-Precision Marking: Line Width <40 μm

- Radial Runout: For Rotary Tubular Instruments <10 μm

- Clear and Stable Engraving with No Visible Deformation or Surface Defects

- Fine Engraving of Complex Patterns on Small and Intricate Structures

Industries Served

- Electronics (3C Structural Parts)

- Consumer Goods Manufacturing

- Precision Hardware Production

Performance and Efficiency

- Maximum Operating Speeds:

- X, Y, Z Axes: 50 mm/s

- θ-Axis: 500 rpm

- Engraving Line Speed: ≤7000 mm/s

- Minimum Character Height: 0.2 mm

- Engraving Depth: 0.2 mm (dependent on material)

Precision and Flexibility

- Positioning Accuracy: ±5 μm

- Repeatability: ±3 μm

- Processing Range: 0~300 mm

- Machining Wall Thickness: 0~2.0 ± 0.02 mm

- Pipe Diameter Processing:

- 0.3~7.0 mm

- 1.0~16.0 mm (optional, customizable clamps available)

- Plane Processing Range: 300 mm × 300 mm

Customizable Features

- Vision Positioning System for Precision Machining

- Real-Time Monitoring with Machine Vision System

- Support for DXF and DWG File Formats

Certified Quality

- ISO9001

- IATF16949

Design and Usability

- Ergonomic and Compact Design

- Flexible Software and Hardware Configuration

- Intuitive Interface for Easy Operation and Intelligent Production Management