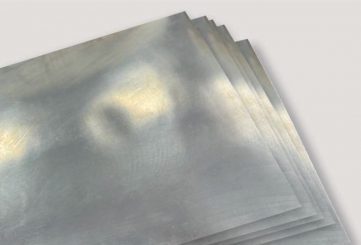

Nitinol Shape Memory Bar (NiTi Bar)

Nitinol Bar: Robust Solid Rods for Heavy-Duty Medical and Orthopedic Uses

Nitinol bar Description:

Solid nitinol rods, forged or extruded, with diameters from 3 mm to 50 mm and lengths reaching 2 meters. Often used as raw material for machining.

Nitinol Shape Memory Rod Key Features:

- Exceptional durability (up to 1200 MPa).

- Fatigue resistance (400 MPa over 10⁶ cycles).

- Robust yet elastic under heavy loads.

Certification and Standards:

- ASTM F2063: General standard for medical nitinol.

- ISO 10993: Ensures biocompatibility for implants.

- ISO 7153: May apply to surgical tools; ASTM F136 if combined with other alloys.

- Often includes manufacturer-specific fatigue and load specs.

Why Nitinol alloy?

Nitinol’s blend of strength, flexibility, and biocompatibility—backed by rigorous standards—revolutionizes medical devices. Curious about specific uses or custom solutions? Contact us for more details!

Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

- Orthopedics: Rods (6–12 mm Ø, 100–400 mm long) reinforce spines or bones, supporting 1000–1500 N.

- Surgical Tools: Machined into 5–20 mm components for endoscopic instruments.

- Prototyping: Larger bars (20–30 mm Ø) craft complex implants like joint parts.

- Diameter: 3–50 mm

- Length: Up to 2 m

- Weight: 5 g/cm (at 10 mm Ø)

- Tensile Strength: 1200 MPa

- Load Capacity: 1000–1500 N