Platinum-Iridium rings (PtIr Rings)

Platinum-Iridium Rings: Durable Circular Components for Precision Medical Uses

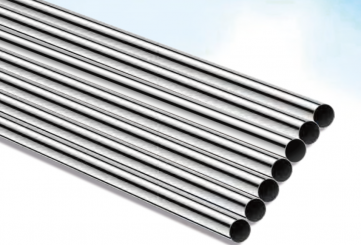

Platinum-Iridium Rings Description:

Small, seamless platinum-iridium rings, formed through precision drawing or forging, with outer diameters ranging from 0,5 mm to 20 mm and wall thicknesses of 0,05–1 mm. These rings leverage the alloy’s robustness for critical medical roles.

Platinum-Iridium Rings Key Features:

- Exceptional corrosion resistance, even in harsh physiological environments.

- High radiopacity due to iridium, enhancing visibility under X-rays.

- Superior hardness (up to 200–300 HV) and wear resistance from iridium addition.

Certification and Standards:

- ASTM F560: Governs unalloyed tantalum and Pt-Ir alloys for surgical implants (applicable to Pt-Ir).

- ISO 5832-1: General standard for metallic surgical implants, adaptable to Pt-Ir.

- ISO 10993: Biocompatibility testing for long-term tissue contact.

- FDA and CE approvals required; often custom manufacturer standards for radiopacity.

Why Platinum-Iridium?

Platinum-iridium’s blend of durability, radiopacity, and biocompatibility—fortified by alloys like 90/10 Pt-Ir and upheld by strict standards—makes it indispensable for cutting-edge medical solutions. Need more details on applications or custom designs? Contact us today!

Platinum-iridium (Pt-Ir), an alloy typically composed of 90% platinum and 10% iridium (though ratios may vary), combines platinum’s ductility and biocompatibility with iridium’s extreme hardness and corrosion resistance. With tensile strength ranging from 900–1200 MPa and a melting point around 1800°C, Pt-Ir is a premium choice for medical devices.

- Vascular Stents: Rings (2–10 mm Ø) form expandable structures to support blood vessels, often in coronary or peripheral applications.

- Surgical Fixation: Used as reinforcing bands (5–15 mm Ø) in orthopedic or neurosurgical implants.

- Catheter Reinforcement: Thin rings (0,5–2 mm Ø) strengthen catheter tips for durability during procedures.

- Diameter: 0,5–20 mm

- Wall Thickness: 0,05–1 mm

- Density: ~21,5 g/cm³ (varies with Pt:Ir ratio)

- Tensile Strength: 900–1200 MPa

- Melting Point: ~1780–1800°C