High Precision products

0 itemsCustom Manufacturing of High-Precision Components According to Customer Specifications

We offer precision manufacturing of high-accuracy components for medical and industrial applications, fully based on customer requirements. All parts are produced according to provided drawings, CAD models, or detailed technical specifications.

Our flexible manufacturing process supports a wide range of custom geometries, critical tolerances, materials, and surface finishes. We work closely with our clients to ensure their specific application needs are met at every stage — from prototyping to series production.

Read more about Application and Key Features…

Application:

High-precision components are essential in a variety of medical and engineering fields that demand exact tolerances and repeatable performance. Typical applications include:

- Micro-mechanical parts for medical devices

- Components for surgical tools and diagnostic equipment

- Precision parts for catheter systems

- Custom inserts, holders, and structural elements for lab setups

- R&D components for clinical testing and prototyping

To discuss your project or request a quote, please contact us with your drawings or technical documentation.

Key capabilities include:

- Manufacturing based on customer drawings and 3D CAD models

- Tight tolerances and high repeatability

- Support for a wide range of metals and polymers

- Micro-machining, laser cutting, drilling, and marking

- Prototyping and small to medium batch production

- Post-processing and surface finishing options upon request

Each order is treated as a custom project, ensuring compliance with your technical requirements and quality standards. Our facility is equipped for contract manufacturing and OEM supply with full documentation and traceability.

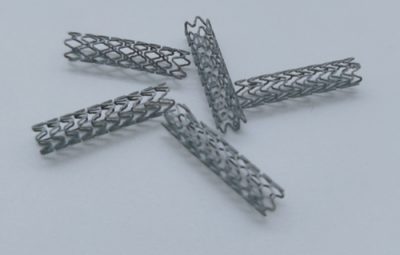

- Stent cutting

- Snake bones

- Hybotube (hipodermic tube)

- Needles

- Surgical instruments

- Medical Devices

- Stainless Steel Cutting and Forming

- Substrates for Electronics Manufacturing

- Hard and Brittle Devices

- Non-Metallic Devices

- Marking and Welding

-

Biodegradable Scaffold

The Degradable Scaffold represents a significant advancement in the field of regenerative medicine. By combining precision laser technology with bioresorbable materials, it provides an effective solution for enhancing tissue regeneration while minimizing the need for secondary surgeries. -

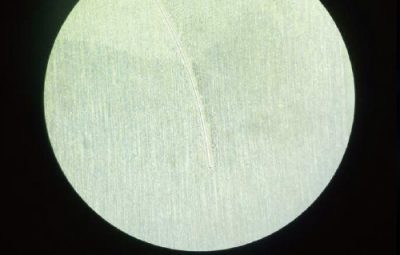

SUS WT-0.1mm W30um D50um Blind Slot

The SUS WT-0.1mm W30um D50um Blind Slot represents a breakthrough in micro-manufacturing, combining cutting-edge laser technology with premium materials. Its exceptional precision and versatility make it the ideal choice for demanding medical and industrial applications. -

3.2mm Magnesium Alloy Stent

The 3.2mm Magnesium Alloy Stent combines advanced manufacturing technology with biocompatible materials to deliver a safe and effective solution for modern vascular treatments. Its biodegradable nature ensures minimal long-term impact, making it an ideal choice for innovative medical applications. -

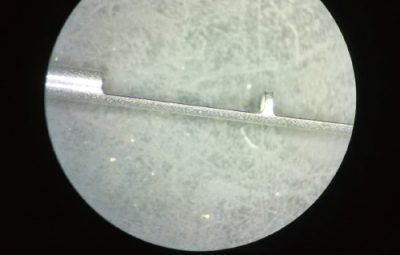

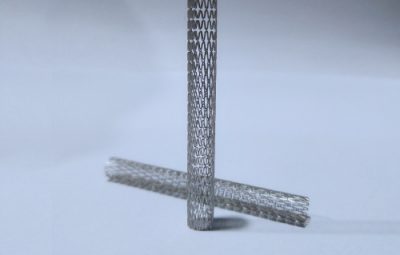

0.36mm-0.254mm Variable Diameter Hypotube

The 0.36mm-0.254mm Variable Diameter Hypotube combines cutting-edge laser micromachining technology with adaptable material options, delivering an ideal solution for advanced medical applications. Its precision and reliability make it a key component in modern healthcare innovations. -

Polylactic Acid Degradable Stent

The Polylactic Acid Degradable Stent is a cutting-edge medical innovation that combines precision engineering with biocompatible materials. Its degradable design ensures effective support during treatment and natural absorption post-procedure, providing a safer, more sustainable solution for modern healthcare needs. -

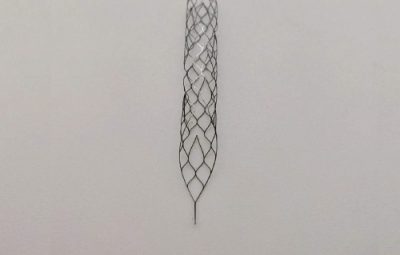

7.0mm Nitinol Extractor

This 7.0mm Nitinol Extractor combines cutting-edge technology with innovative material properties to deliver a reliable, efficient solution for medical professionals worldwide. Perfect for critical interventions requiring precision and adaptability, it is a trusted choice in modern medical device engineering. -

6.5mm Magnesium Alloy Filter

The 6.5mm Magnesium Alloy Filter is a top-tier solution for advanced filtration needs, blending precision engineering with superior material properties. Its versatility and reliability make it a preferred choice for cutting-edge medical and industrial applications. -

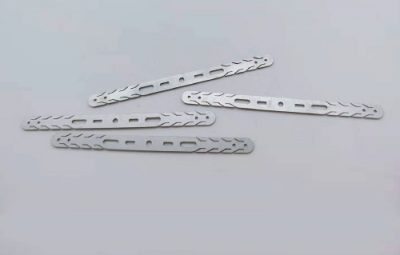

Zinc Flakes

Zinc Flakes represent the pinnacle of precision manufacturing, offering exceptional quality and adaptability for a wide range of applications. Their ultrathin structure and high conductivity make them an excellent choice for industries requiring advanced material solutions. -

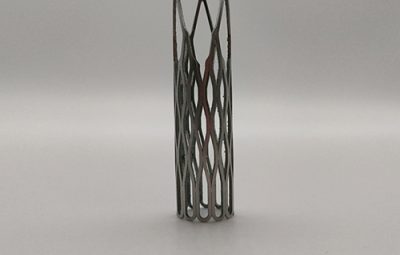

Valve Stent Microstructure Ni-Ti 7mm WT0.4mm

The Ni-Ti-Ф7mm-WT0.4mm Valve Stent Microstructure represents a cutting-edge advancement in cardiovascular stent technology, specifically designed for valve repair and replacement applications. -

Mitral Stent Ni-Ti 5mm WT0.3mm

The Ni-Ti Ф5mm WT0.3mm Mitral Stent is a state-of-the-art medical device engineered for precision mitral valve interventions. -

Valve stent NiTi & L605 D23mm WT0.5mm

This valve stent is a high-performance medical device designed for durability and precision. -

Valve stent Ni-Ti 9.5mm WT0.5mm

The Ni-Ti 9.5mm WT0.5mm Valve Stent is a high-precision medical component, engineered for advanced cardiovascular applications, particularly valve repair and replacement. -

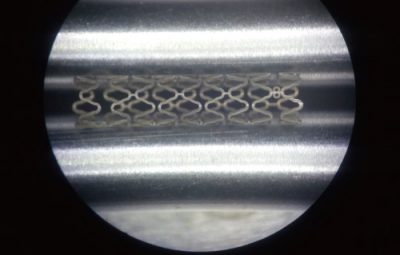

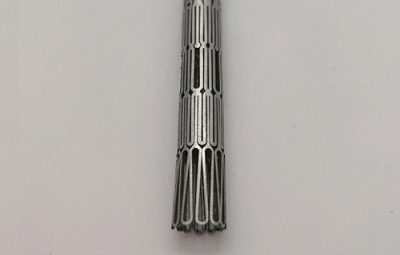

9.5mm Blind engraving of stainless steel tube

The 9.5mm Blind Engraving of Stainless Steel Tube is a high-precision medical component designed for advanced applications in the production of cardiovascular and other medical devices. -

0.15 mm Stainless Steel Tube

The 0.15 mm Stainless Steel Tube Forming is a precision-engineered component designed for ultra-fine medical applications. -

Mitral stent NiTi 5.5mm WT0.3mm

The Ni-Ti-5.5mm-WT0.3mm Mitral Stent is a high-precision medical device designed for mitral valve repair and replacement.