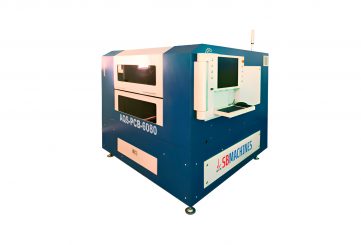

AQS-HB-6045 Laser cutting machine for precision hard and brittle materials

AQS-HB-6045 Laser cutting machine for precision hard and brittle materials – micrometer-grade cutting of ceramics, sapphire, diamond and tungsten steel

AQS-HB-6045 is a fiber-laser micromachining platform engineered for plane and regular-surface parts made from high-hardness, high-brittleness materials such as alumina/zirconia ceramics, sapphire, diamond, silicon, germanium, gallium arsenide and tungsten steel. It is built to deliver ultra-stable cutting with a narrow kerf and minimal heat-affected zone on workpieces up to a 300 × 300 mm table size.

The system combines a self-developed direct-drive precision motion platform with proprietary cutting heads and CAM software, enabling consistent, repeatable results in demanding semiconductor, electronics and precision-engineering workflows.

Scope of application

AQS-HB-6045 performs laser cutting, drilling, slotting and scribing on flat and regular-surface components made from hard and brittle substrates (ceramics, sapphire, diamond, tungsten steel and more). Typical use cases span semiconductor substrates, micro-mechanical parts and precision electronic components.

Advantages

- Kerf width as small as 15–30 μm, supporting miniature geometries.

- High machining accuracy to ≤ ±10 μm for stable dimensional control.

- Smooth cuts with a small heat-affected zone and edge chipping < 15 μm to reduce post-processing.

- Minimum product size down to 100 μm for true micro-feature fabrication.

High finishing

The machine’s fiber laser source (1030–1070 nm) and optimized optics deliver clean edges and surface integrity on brittle materials. With wall thickness capability up to 0–2.0 ± 0.02 mm, the process maintains quality while protecting sensitive substrates from thermal stress.

Benefits:

- Burr-free edges and glossy cut faces that minimize downstream polishing.

- Tight positional performance: positioning accuracy down to ±3 μm (X/Y) with repeatability to ±1 μm (X/Y), supporting high-yield, high-mix production.

Strong adaptability

Beyond cutting, AQS-HB-6045 supports drilling, slotting and scribing on alumina, zirconia, aluminum nitride, silicon nitride, silicon, sapphire, diamond, gallium arsenide, tungsten steel and more—covering the mainstream hard-and-brittle substrate set used in electronics and optics.

Hardware choices include granite/aluminum-granite beams, a granite base, and a self-developed direct-drive dual-drive stage. Optional dual-station layout, visual positioning, automatic loading/unloading, dynamic process monitoring, modular dust extraction, vacuum/honeycomb/tension fixtures, and in-house 2D/2.5D/3D CAM software allow you to tailor the system to your process.

Flexible design

The system follows an ergonomic, compact design and an open control philosophy, so operators work through an intuitive interface while engineers can scale capabilities as requirements evolve.

Highlights:

- Modular software/hardware configuration for personalized functions and intelligent production management.

- Choice of laser options (e.g., CW 1000 W; QCW 150/300/450 W) to balance throughput and edge quality on different materials.

Technical certification

AQS-HB-6045 is produced under certified quality systems, including ISO 9001 and IATF 16949, supporting consistent manufacturing and traceability for regulated industries.

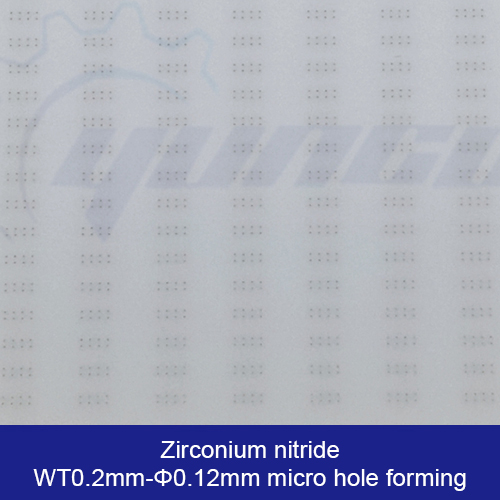

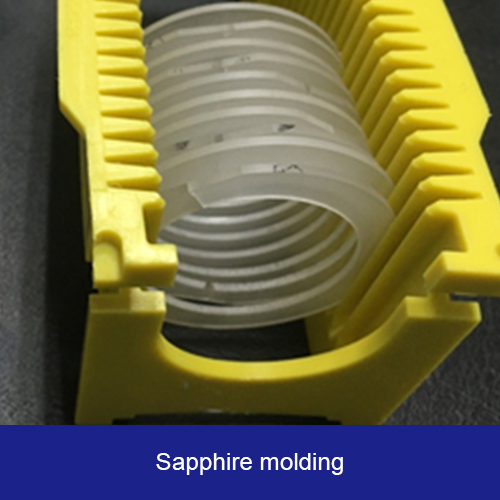

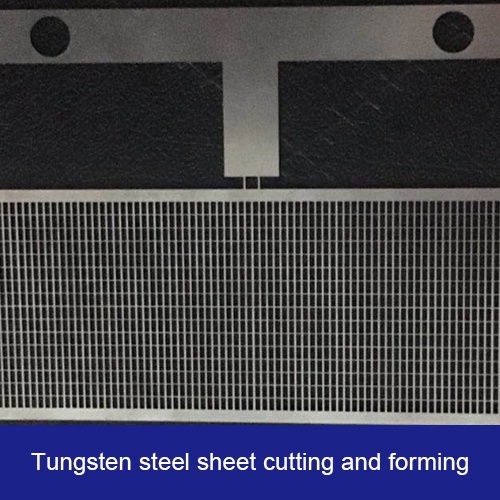

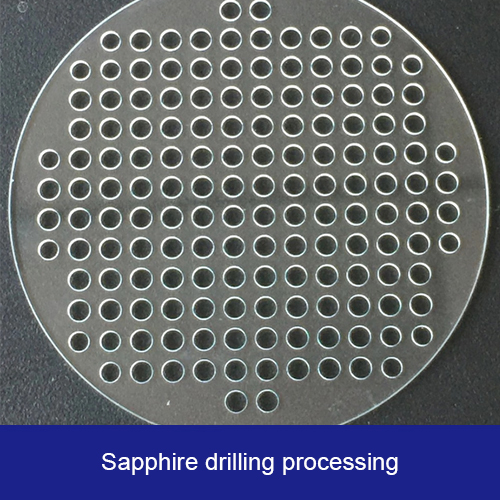

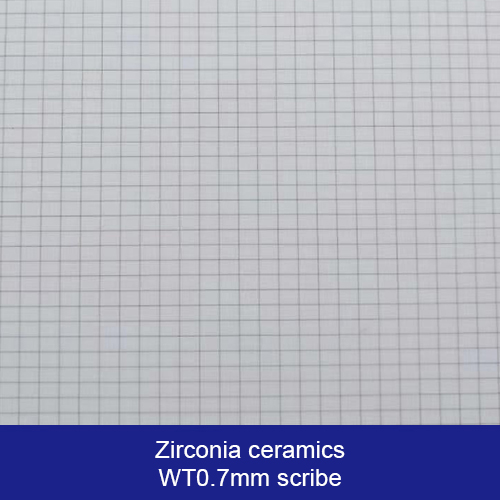

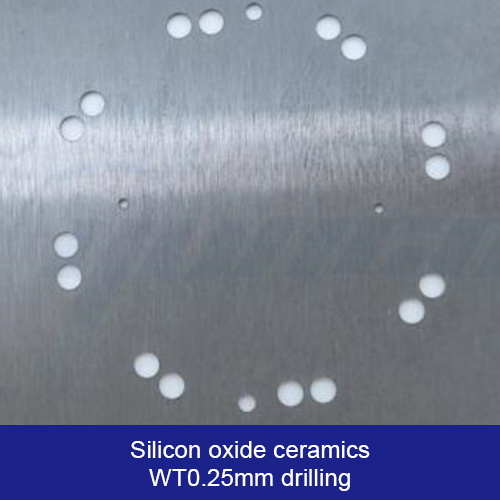

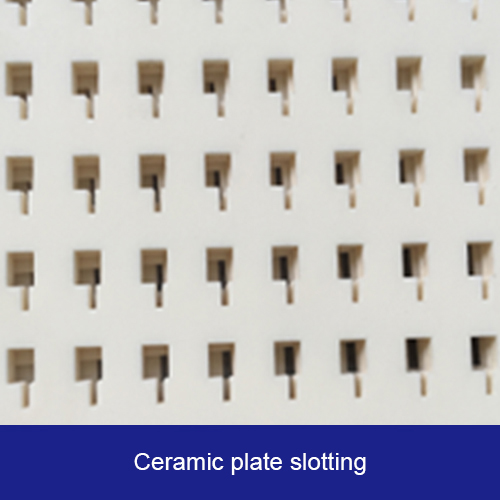

Sample Display

Processing Materials:

- Alumina Engineering ceramic (Al₂O₃) with high hardness, chemical resistance and excellent electrical insulation. Suitable for thin, clean laser cuts with minimal chipping when parameters are optimized.

- Zirconia Toughened ceramic (ZrO₂) with high fracture toughness and thermal-shock resistance. Ideal for precision medical and industrial parts; requires fine control to avoid micro-cracks.

- Aluminum Nitride Ceramic with very high thermal conductivity and strong electrical insulation. Common for substrates and heat spreaders; benefits from inert assist gas during laser cutting.

- Silicon Nitride High-strength, tough ceramic (Si₃N₄) resistant to wear and thermal cycling. Produces narrow-kerf laser cuts for bearings, turbine and electronics components.

- Diamond Ultra-hard, high-thermal-conductivity material for wear parts and dies. Best processed with ultra-short-pulse or green lasers to limit graphitization and edge damage.

- Sapphire Single-crystal alumina with optical clarity and extreme scratch resistance. Used for windows and LED substrates; absorbs better at green/UV wavelengths for clean edges.

- Silicon Semiconductor with good IR absorption, widely used in wafers and MEMS. Supports precise laser scribing and cutting with a small heat-affected zone.

- Germanium Brittle semiconductor for IR optics with strong IR absorption and high refractive index. Requires careful thermal management to prevent cracking.

- Gallium Arsenide Compound semiconductor for RF and optoelectronics. Brittle and hazardous dust—use extraction; green/UV lasers help control the heat-affected zone.

- Tungsten Steel Wear- and heat-resistant tool steel alloyed with tungsten (often HSS/carbide-grade). Demands high power density and proper assist gas for oxidation-free, crack-free edges.

Laser Specifications:

- Fiber-optic laser

- Wavelength: 1030~1070±10nm

- Power Options: CW1000W, QCW150W, QCW300W, QCW450W

- Cutting Seam Width: 15~30μm

- Material Wall Thickness: 0~2.0±0.02mm

Scope of Use:

- Laser micromachining of high-hardness and high-brittleness materials

- Processing flat and regular surface instruments made of ceramics, sapphire, diamond, tungsten steel, and others

Processing Capabilities:

- High machining accuracy: ≤±10μm

- Smooth incision with minimal heat-affected zone

- Edge chipping: <15μm

- Minimum product size: 100μm

Industries Served:

- Semiconductor manufacturing

- Electronics production

- Precision engineering

Performance and Efficiency

Maximum Operating Speeds:

- X, Y1, Y2 Axes: 1000mm/s

- Z Axis: 50mm/s

Positioning Accuracy:

- ±3μm (X, Y1, Y2)

- ±5μm (Z)

Repeatability:

- ±1μm (X, Y1, Y2)

- ±3μm (Z)

Advanced Features

- Self-developed direct-drive motion platform with precision control

- Optional visual positioning and dynamic monitoring systems

- Modular feed and dust ductwork

- Multiple fixture options: vacuum adsorption, honeycomb panels, tension frames

Certified Quality

- ISO9001

- IATF16949

Design Excellence

- Ergonomic and compact design

- Flexible hardware and software configuration for customized needs

- User-friendly interface with self-developed 2D, 2.5D, and 3D CAM software systems