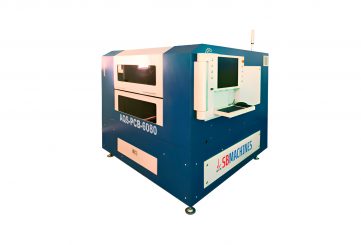

AQS-SE-6080 Laser cutting machine for precision 2D steel equipment

AQS-SE-6080 Laser Cutting Machine for Precision 2D Steel Equipment – High-accuracy 2D metal micromachining

The AQS-SE-6080 is a high-precision 2D laser cutting system engineered specifically for processing flat and curved steel instruments, such as precision stainless steel or carbide steel parts, whether before or after surface treatment. This machine integrates advanced laser optics, motion control, and thermal stability to deliver microscale cutting quality with minimal heat-affected zones and smooth edges.

With its compact and robust structure, the AQS-SE-6080 ensures consistent performance even under demanding production environments. Its control system and automation-friendly features make it a reliable solution for industries requiring fine metal components with tight tolerances.

Scope of application

The AQS-SE-6080 is ideal for industries and applications that demand ultra-fine steel component fabrication, such as precision tools, medical devices, instrumentation, micro-mechanical systems, and specialty parts manufacturing. It is well suited for cutting thin to moderately thick steel plates and components where surface integrity, dimensional accuracy, and edge quality are critical.

Advantages:

- Capable of producing complex 2D shapes with micrometer-level precision

- Minimal thermal distortion or warpage

- High reproducibility across batches

- Suitable for both prototyping and small to mid volume production

High finishing

This machine achieves superior surface finish by combining precise laser control and stable mechanical structure, reducing burrs and hotspots. The result is smooth, narrow kerf widths and minimal post-processing:

Advantages:

- Very narrow cutting slit width for fine detail

- High machining accuracy with minimal deviation

- Smooth edges with almost no burrs or recast layer

- Small heat-affected zone, preserving material properties

Strong adaptability

The AQS-SE-6080 is designed to handle a wide range of steel types and plate geometries while adapting to different production needs. It can process varying materials such as stainless, carbon, or hardened steel, and it supports pretreated or coated surfaces without compromising cut quality. The system architecture accommodates upgrades and custom modules — for example, automatic loading/unloading, vision alignment, and specialized fixtures — making it versatile across diverse manufacturing setups.

Flexible design

The machine follows a modular and ergonomic design philosophy, allowing users to tailor software and hardware configurations to their process requirements. Its structure supports expansion and integration with factory automation systems.

Advantages:

- Modular software/hardware combinations and customizable function sets

- Ergonomic and compact layout for ease of operation and maintenance

- Support for intelligent production management and remote control

- Open control architecture with intuitive user interface

Technical certification

The AQS-SE-6080 is manufactured under recognized quality systems and undergoes rigorous inspection and calibration. It meets industry standards for precision manufacturing and ensures reliable performance and traceability across production cycles.

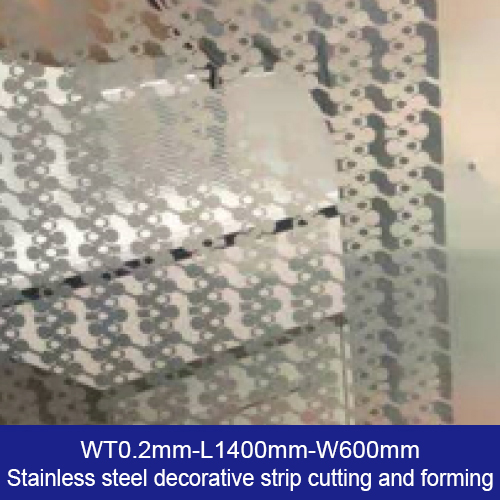

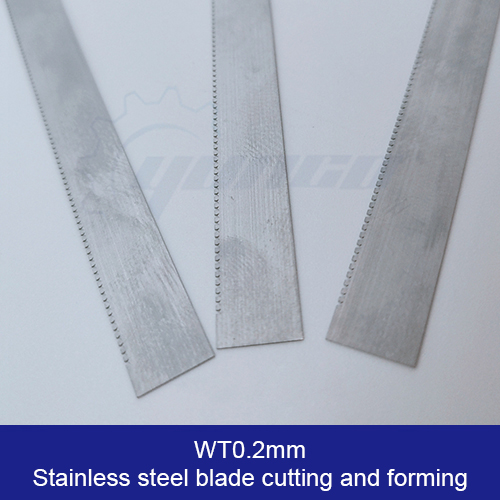

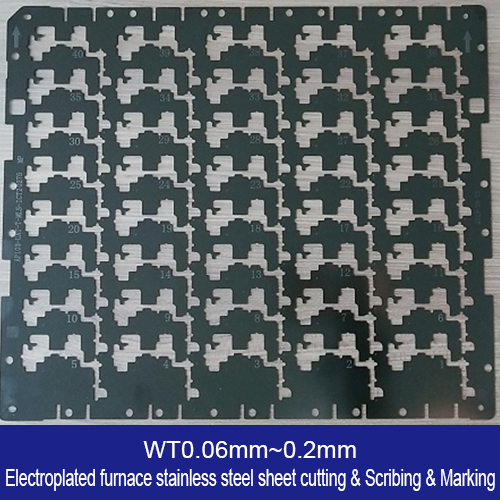

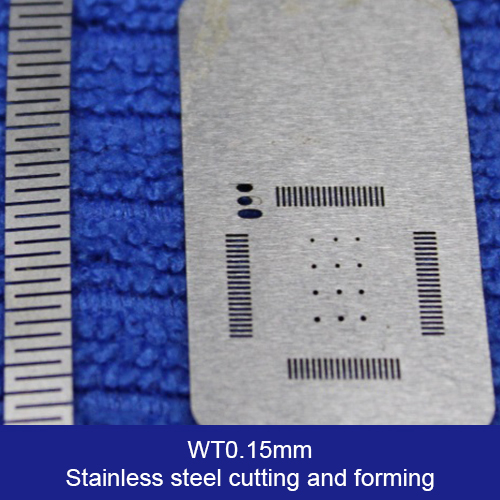

Sample display

Processing Materials:

- Carbide steel Carbide steel is a durable alloy known for its exceptional hardness, wear resistance, and strength, making it ideal for producing precision components and tools that must withstand high stress and intensive use. Materials can be processed both before and after surface treatment.

Laser Specifications:

- Fiber-optic laser with wavelength 1030~1070±10nm

- Power Options: CW200W, 250W, 300W, 500W, 1000W, QCW150W

- Cutting Seam Width: 15~30μm

- Material Wall Thickness: 0~2.0±0.02 mm

Scope of Use

Precision laser micromachining for:

- Stainless steel instruments

- Carbide steel instruments

- Semiconductor integrated circuit manufacturing

Processing Capabilities

- Cutting, drilling, and slotting with high precision

- Smooth incisions with minimal heat-affected zone and burr-free edges

- Minimum product size: 20μm

Industries Served

- Semiconductor industry

- Precision metalworking for high-performance steel equipment

Performance and Efficiency

Table size (mm): 600х800

WT: 0~2.0±0.02 mm

Maximum Operating Speeds:

- X, Y1, Y2 Axes: 1000mm/s

- Z Axis: 50mm/s

Positioning Accuracy:

- ±3μm (X, Y1, Y2)

- ±5μm (Z)

Repeatability:

- ±1μm (X, Y1, Y2)

- ±3μm (Z)

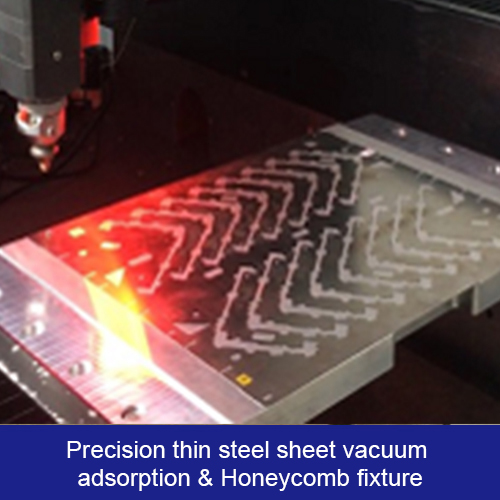

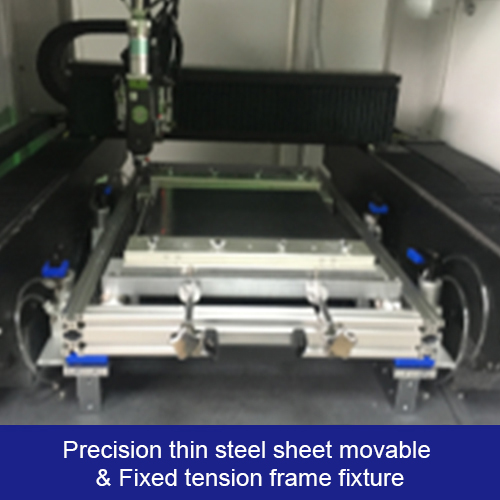

Advanced Features

- Double station and visual positioning options

- Automatic loading and unloading system with dynamic processing monitoring

- Self-developed sharp & flat fine laser cutting head with long and short focal length options

- Modular feed and dust removal system

- Optional fixtures: movable tension frame, fixed tension frame, vacuum adsorption, honeycomb board

Certified Quality

- ISO9001

- IATF16949

Design Excellence

- Ergonomic, compact, and modular design

- Self-developed 2D, 2.5D, and 3D CAM software for flexible production management

- Intuitive interface with customizable software and hardware configurations