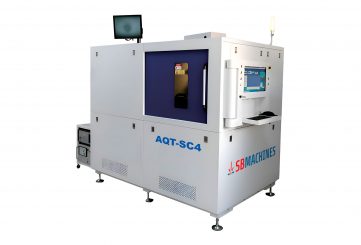

AQT-ND Laser processing center for medical needles

AQT-ND Laser Processing Center – ultra-precise laser micromachining for medical-grade needles

The AQT-ND Laser Processing Center is a dedicated high-precision platform for manufacturing indwelling, puncture, biopsy, and RF ablation needles. Designed to meet the demanding requirements of medical device production, it delivers exceptional finishing quality, adaptability to complex geometries, and seamless integration into automated workflows.

Scope of Application

The AQT-ND system is engineered for processing thin-walled medical tubes into high-performance needles. It supports equal-diameter, reducer, deformed, and flat tubes, enabling manufacturers to produce a wide range of needle types with precision. Its robust functionality makes it ideal for both prototyping and high-volume production.

AQT-ND Laser processing center Key features:

- Effective processing of stainless steel, Ni-Ti alloys, cobalt alloys, and similar materials

- Wide coverage of different medical needle types

- Reliable performance for critical medical applications

High Finishing

Equipped with advanced laser optics and motion control, the AQT-ND achieves a cutting seam width of 18–30 μm and machining accuracy of ≤ ±10 μm. Surfaces are burr-free and smooth, eliminating the need for extensive post-processing and ensuring patient safety.

- Ultra-fine seams with precise control

- Burr-free and smooth edges

- Maintains structural and functional integrity of delicate tubes

Strong Adaptability

The system supports dry and wet cutting, drilling, grooving, slotting, tapering, and other operations. Automated loading and unloading combined with high-precision collet systems provide stable clamping and repeatable accuracy, even for the most delicate thin-walled tubes.

- Flexible processing modes for diverse geometries

- Automatic feeding and precise clamping systems

- Compatibility with D-type, ER, and 3-jaw collets

Flexible Design

With integrated 2D, 2.5D, and 3D CAM software, the AQT-ND offers intelligent process planning and execution. Optional machine vision enables real-time monitoring, while its open-interface design ensures compatibility with automated production lines and future digital manufacturing upgrades.

- Smart CAM programming for complex cutting paths

- Real-time quality monitoring via machine vision

- Open design for seamless automation integration

Technical Certification

The AQT-ND is produced under strict quality management systems with complete traceability and validation of processes. Fully certified under ISO9001 and ISO13485, it meets international medical device manufacturing requirements for precision, safety, and repeatability.

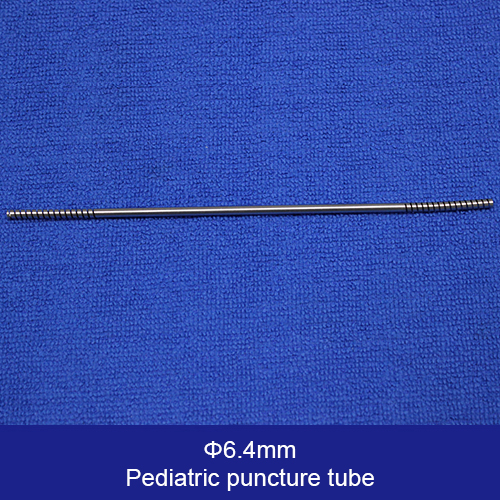

Sample display

Processing Materials:

- 304 Stainless Steel

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

- 316L Stainless Steel

- Ni-Ti Alloys

- L605 Alloy

- Other Alloys

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

316L Stainless Steel is a medical-grade austenitic chromium-nickel alloy renowned for its excellent corrosion resistance and biocompatibility. With a tensile strength of approximately 485–550 MPa and elongation up to 40%, it offers durability and flexibility without brittleness. Its low carbon content enhances weldability and resistance to intergranular corrosion, making it ideal for medical implants and instruments. Laser-machined for smooth, burr-free surfaces, it minimizes tissue irritation in sensitive applications.

Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

Cobalt-Chromium Alloys (L605) are medical-grade materials valued for their exceptional strength, corrosion resistance, and biocompatibility. With tensile strength ranging from 800–1500 MPa and hardness of 300–550 HV, they ensure durability in demanding medical applications. Ideal for implants and surgical tools, they support direct tissue contact with minimal reaction. Laser-machined surfaces provide smooth, burr-free finishes, enhancing performance in sensitive procedures.

Clamping Systems:

- Precision D-Type Collets

- ER Series Collets

- Three-Jaw Chucks

Laser Specifications:

- Fiber-Optic Laser

- Wavelength: 1030~1070nm±10nm

- Power Options: 100W, 200W, 250W, 300W, 500W

Scope of Use:

Laser Micromachining for Needles:

- Indwelling Needles

- Puncture Needles

- Radiofrequency Ablation Needles

Processing of Tubes and Instruments:

- Equal-Diameter, Deformed, and Semi-Finished Tubes

- Small-Format Flat Instruments

Processing Capabilities:

- Laser Cutting, Drilling, and Grooving

- High Finishing: Cutting Seam Width 15~25 μm

- High Machining Accuracy: ≤ ±10 μm

- Continuous Automatic Feeding Processing

- One-Time Cutting Through One-Sided Pipe Wall

Industries Served:

- Medical Equipment Manufacturing

- Surgical Instrument Production

Performance and Efficiency:

- Maximum Operating Speeds:

- X-Axis: 300 mm/s

- Y and Z-Axis: 100 mm/s

- θ-Axis: 600 rpm

Precision and Versatility:

- Positioning Accuracy: ±2~±3 μm

- Repeatability: ±0.5~±1 μm

- Processing Wall Thickness: 0~0.5 ± 0.02 mm

- Pipe Diameter Processing Range: 0.1~7.5 mm / 0.3~16.0 mm

Customizable Features:

- Tube Blank Length: <2.5 m (Customizable Fixtures Available)

- Single Processing Range: 0~300 mm (Segmented Splicing for Longer Products)

- Compatible File Formats: DXF, DWG

Certified Quality:

- ISO9001, ISO13485 Certifications

Design and Usability:

- Ergonomic and Compact Design

- Optional Machine Vision System for Real-Time Process Monitoring

- Flexible Software & Hardware Configuration for Personalized Production Needs

- Easy Operation with Open Control Software and Intuitive Interface