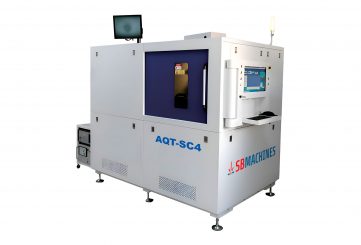

AQT-SC3 Laser cutting machine for large medical stents

AQT-SC3 Laser Cutting Machine – High-Precision Cutting for Large Medical Stents

The AQT-SC3 is a high-performance laser cutting machine specifically engineered for the production of large metallic stents (bare metal and drug-coated), including stents for heart valves, mitral valves, peripheral arteries, and lower limbs. It combines precision, stability, and the ability to process both thick-walled and thin-walled large-diameter tubes with minimal distortion.

With powerful laser cutting, automatic feeding, and a wide material compatibility, the AQT-SC3 is the ideal choice for manufacturers who demand uncompromising quality and efficiency in the medical device industry.

Scope of application

The AQT-SC3 is designed for cutting large medical stents — both bare metal and drug-coated — especially in cardiovascular and peripheral applications. It delivers superior cutting accuracy, clean edges, and high production efficiency to meet the strict requirements of modern medical manufacturing.

Advantages:

- Supports stents with large diameters and thick walls.

- Multiple processing methods: dry cutting, wet cutting, drilling, blind slot digging, and compound cutting.

- Compatible with equal-diameter and tapered tubes, including vertical, centripetal, and compound cuts.

High finishing

- Cutting seam width < 20 μm

- Processing accuracy ≤ ±5 μm

- Smooth and burr-free edges with minimal heat-affected zones

High finishing quality is essential in medical stent production. The AQT-SC3 ensures a narrow seam, smooth edges, and consistent geometry even in complex structures.

Strong adaptability

The AQT-SC3 is highly adaptable to a wide range of cutting requirements. It supports multiple cutting modes (dry, wet, slotting, drilling) and is capable of processing thin-walled and thick-walled tubes alike, across a wide variety of medical materials such as 316L stainless steel, Ni-Ti alloys, L605, Fe, Mg, and Zn.

The system also offers flexibility in workholding solutions — from high-precision D-type and ER-series collets to three-jaw chucks. Automatic feeding, sealing, splicing, and integrated CAM software (supporting 2D, 2.5D, and 3D micro commands) make the AQT-SC3 a comprehensive solution for advanced stent manufacturing.

Flexible design

The AQT-SC3 features a flexible machine design, allowing easy adaptation to customer requirements and long-term scalability.

- Ergonomic, compact design for easy integration and operation

- Optional machine vision system for real-time monitoring of the laser cutting process

- Flexible hardware and software configuration to meet personalized production needs

- Open control software with an intuitive interface

Technical certification

The AQT-SC3 is certified according to ISO 9001 and ISO 13485, ensuring full compliance with international medical device manufacturing and quality management standards.

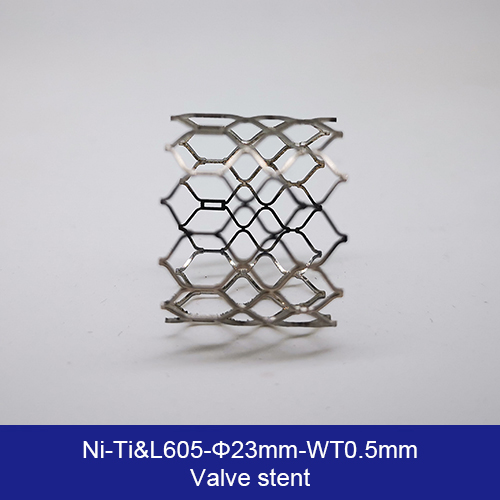

Sample display

316L Stainless Steel:

316L Stainless Steel is a medical-grade austenitic chromium-nickel alloy renowned for its excellent corrosion resistance and biocompatibility. With a tensile strength of approximately 485–550 MPa and elongation up to 40%, it offers durability and flexibility without brittleness. Its low carbon content enhances weldability and resistance to intergranular corrosion, making it ideal for medical implants and instruments. Laser-machined for smooth, burr-free surfaces, it minimizes tissue irritation in sensitive applications.

Nickel-Titanium alloy:

Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

Cobalt-Chromium Alloys (L605):

Cobalt-Chromium Alloys (L605) are medical-grade materials valued for their exceptional strength, corrosion resistance, and biocompatibility. With tensile strength ranging from 800–1500 MPa and hardness of 300–550 HV, they ensure durability in demanding medical applications. Ideal for implants and surgical tools, they support direct tissue contact with minimal reaction. Laser-machined surfaces provide smooth, burr-free finishes, enhancing performance in sensitive procedures.

Iron (Fe):

A strong, durable metal used in some surgical instruments and structural components. Its high strength and cost-effectiveness make it suitable for non-implantable medical tools.

Magnesium alloy:

Magnesium, a lightweight (1.74 g/cm³) and biodegradable metal, is ideal for temporary medical implants like stents and orthopedic screws. Alloys such as WE43 or JDBM offer tensile strength (200–420 MPa) and controlled degradation (6–24 months), safely dissolving into non-toxic byproducts (Mg²⁺ ions). Its biocompatibility (ISO 10993) and ability to support tissue regeneration make it suitable for cardiovascular and bone repair applications. Magnesium’s elastic modulus closely matches bone, minimizing stress shielding in orthopedic uses.

Magnesium (Mg)

Magnesium is a biodegradable and biocompatible material widely researched for medical implants. In stent manufacturing, it offers controlled degradation inside the human body, reducing the need for secondary surgeries and supporting natural tissue healing.

Zinc (Zn)

Zinc is a promising bioresorbable metal with excellent biocompatibility and corrosion control. In medical applications, zinc-based alloys are used for stents and implants, providing mechanical strength while gradually resorbing in the body without toxic effects.

Other Alloy Materials

Scope of Use:

Medical Stents:

- Heart Valve

- Mitral Valve

- Peripheral and Lower Extremity Bare Metal Stents

- Drug-Coated Stents

Processing Capabilities:

- Laser Dry Cutting, Wet Cutting, Drilling, and Blind Slot Digging

- Centripetal, Vertical, and Compound Opening Features for Equal Diameter and Reducer Tubes

- Sealing and Splicing of Precision Thin-Walled Tubes

Industries Served:

- Interventional Medical Equipment Manufacturing

Key Features:

- Cutting Seam Width: 15~25 μm

- High Machining Accuracy: ≤ ±5 μm

- Positioning Accuracy: X-Axis: ±1 μm / Y & Z Axes: ±3 μm

- θ-Axis: ±15 arcsec

High Performance:

Maximum Operating Speeds:

- X-Axis: 300 mm/s

- Y-Axis: 100 mm/s (optional)

- Z-Axis: 100 mm/s

- θ-Axis: 600 rpm

Versatility:

- Process Wall Thickness: 0~1.0 ± 0.02 mm

- Tube Diameters:

- 0.3–16.0 mm

- 1.0–30.0 ± 0.02 mm

- Tube Blank Length: <2.5 m (customizable fixtures available)

Flexibility and Customization:

- Continuous Automatic Feeding for Precision Tubes

- Compatible File Formats: DXF, DWG

- Supports 2D, 2.5D, and 3D CAM Software for Precision Machining

Certified Quality:

- ISO9001, ISO13485 Certifications

Intuitive Design:

- Ergonomic Machine Design with Real-Time Vision System

- Customizable Software & Hardware Configuration for Intelligent Production Management

Compatible Clamping Systems:

- Precision D-Type Collets

- ER Series Collets

- Three-Jaw Chucks

Laser Type and Specifications:

- Type: Fiber-Optic Laser

- Wavelength: 1030~1070 ± 10 nm

- Power Options: 200W, 300W, 500W

Power:

- Standard Laser Power: 100W, 200W, 250W, 300W

- Optional Laser Power: 500W, QCW 150W