0.36mm-0.254mm Variable Diameter Hypotube

0.36mm-0.254mm Variable Diameter Hypotube – Ultra-Precision Tube for Micro-Catheter Applications

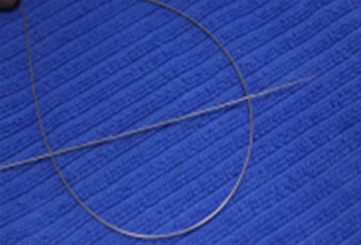

The 0.36mm-0.254mm Variable Diameter Hypotube is an ultra-precision medical tube designed for micro-catheter and endoscopic systems. Crafted from medical-grade SUS304 stainless steel, this hypotube features a variable diameter design for enhanced flexibility and navigation in intricate anatomical pathways during minimally invasive procedures. Produced using advanced laser micromachining, it ensures burr-free surfaces and precise dimensions, facilitating seamless integration into medical devices while maintaining corrosion resistance and biocompatibility.

Key Features:

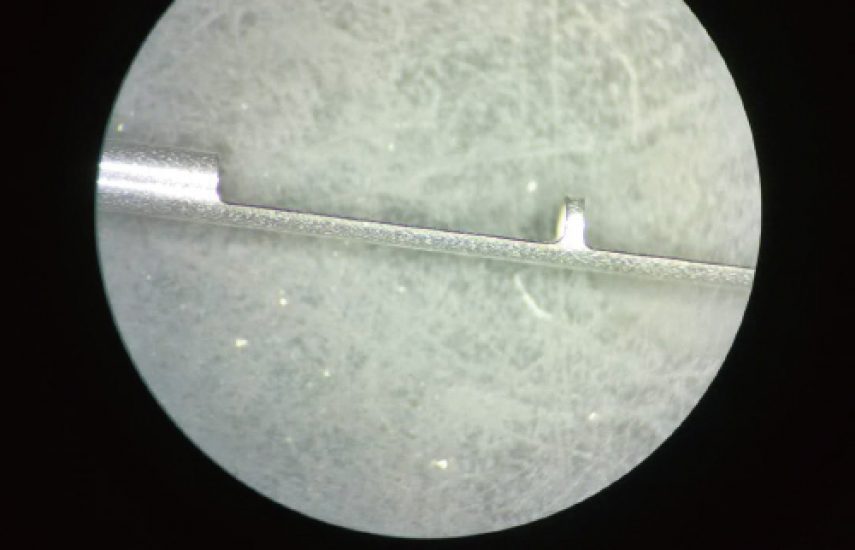

- Ultra-High Precision: Laser-machined with cutting seam widths of 15–30μm and accuracy of ≤±10μm for burr-free, smooth surfaces.

- Variable Diameter Design: Enables adaptable flexibility for micro-catheter applications in complex anatomies.

- Biocompatibility: Hypoallergenic material minimizes tissue reaction, ideal for direct contact in sensitive procedures.

- Superior Durability: High tensile strength and corrosion resistance ensure reliable performance in physiological environments.

- Efficient Integration: Compatible with various clamping systems and cutting methods for rapid assembly.

- Sterility Maintenance: Smooth finish reduces contamination risks and supports sterilization processes.

Certification and Standards:

The 0.36mm-0.254mm Variable Diameter Hypotube complies with ISO 13485 quality management standards for medical devices and adheres to biocompatibility requirements under ISO 10993.

- Ni-Ti (Nickel-Titanium): Known for its superelasticity and shape memory, ideal for flexible medical devices like catheters and endoscopes.

- 316L Stainless Steel: Austenitic stainless steel with excellent corrosion resistance and biocompatibility, widely used in medical implants and tubes.

- L605 (Cobalt-Chromium Alloy): Offers high strength, corrosion resistance, and durability, suitable for demanding medical and industrial applications.

- Mg (Magnesium): Lightweight and biodegradable, used in temporary medical implants with good biocompatibility.

- Zn (Zinc): Provides moderate corrosion resistance and biocompatibility, often used in bioresorbable medical devices.

- Micro-Catheter Systems: Facilitates precise navigation in vascular or urological procedures requiring ultra-fine tubes.

- Endoscopy Systems: Supports flexible articulation in micro-endoscopes for minimally invasive interventions.

- Guidewire Integration: Integral to constructing variable guidewire systems with high-precision requirements.

- Medical Device Repair: Employed in maintenance or replacement of micro-tube components in catheter and endoscopic systems.

- Specialized Medical Designs: Adaptable for investigational or custom devices needing advanced flexibility in cardiology or neurology.

- Material Composition: SUS304 stainless steel.

- Dimensions: Diameter range: 0.36mm–0.254mm.

- Cutting Seam Width: 15–30μm.

- Machining Accuracy: ≤±10μm.

- Manufacturing Process: Advanced laser micromachining with continuous automatic feeding for burr-free, smooth finish.

- Clamping Compatibility: D-type collets, ER-series collets, three-jaw chucks.

- Cutting Methods: Dry or wet cutting options.

- Packaging: Sterilized and individually packaged to maintain integrity.

- Storage Conditions: Store in a dry, cool environment to prevent corrosion.