Peeling Paint on the Surface of the Middle Frame of the Mobile Phone

Peeling Paint on the Surface of the Middle Frame of the Mobile Phone – high-precision paint removal solution for mobile frame parts

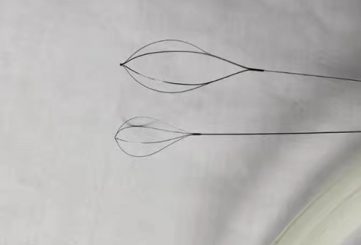

The Peeling Paint on the Surface of the Middle Frame of the Mobile Phone is a high-precision laser processing service designed for the controlled removal of paint from the middle frames of mobile phones. Using advanced UV laser technology, this service delivers ultra-fine results with minimal impact on surrounding material. It’s ideal for manufacturers and repair services that require smooth, clean surfaces without deformation or damage to the substrate.

Key Features:

- High precision: line width < 40 µm

- Smooth finish: no deformation, bumps, or pits

- Efficient processing: automatic clamping and positioning

- Material versatility: compatible with stainless steel, aluminum, and other metals

- Advanced workflow: 2D / 2.5D CAM software control

Certification and Standards:

Produced under rigorous quality management with traceable processes and inspection. Compliance with applicable ISO manufacturing standards for precision laser processing and metal finishing.

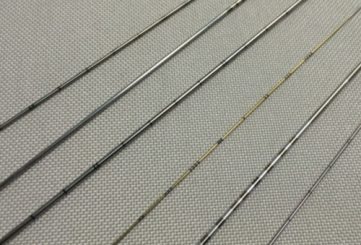

Stainless Steel SUS304:

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

Aluminum alloy:

Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

Other Metals

- Mobile phone manufacturing: controlled paint removal on middle frames.

- Refurbishment & repair: restore surfaces for resale and cosmetic quality.

- 3C electronics: precision surface processing with tight visual tolerances.

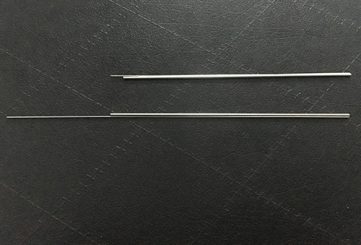

- Technology: UV laser system, line width < 40 µm.

- Surface outcome: smooth finish; no pits, bumps, or deformation.

- Materials: stainless steel, aluminum, and compatible metal alloys.

- Fixturing: automatic clamping and positioning for repeatability.

- Software: 2D / 2.5D CAM control for consistent processing paths.