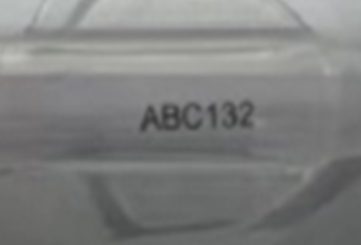

Plastic Handle Marking

Plastic Handle Marking – durable, precise laser marking for plastic medical handles

Plastic Handle Marking is a high-precision laser process engineered to create permanent, clear, and biocompatible markings on plastic handles used in medical instruments and devices. Unlike inks or labels, laser marking ensures durability, hygiene, and resistance to sterilization processes. The markings can include identification codes, logos, graduations, or other functional designs, all applied without damaging the material surface or compromising structural integrity.

Key features:

- Non-contact laser process: no mechanical stress or risk of contamination

- Permanent and wear-resistant: markings withstand sterilization, abrasion, and cleaning

- High contrast visibility: clear, sharp markings on various medical-grade plastics

- Customizable content: text, serial numbers, logos, or scale indicators possible

- Environmentally friendly: no inks, coatings, or consumables required

Certification and Standards:

Produced under ISO9001 and ISO13485 certified quality systems; the process complies with international medical device standards ensuring traceability, reliability, and biocompatibility.

Plastic

Plastic is widely used in the manufacturing of medical devices due to its lightweight properties, cost-effectiveness, and design flexibility. Medical-grade plastics are biocompatible, resistant to corrosion and chemicals, and can withstand sterilization processes, making them safe for direct contact with patients. Their versatility allows the production of complex shapes and components with consistent quality, supporting innovation in surgical instruments, diagnostic equipment, and disposable medical products.

- Plastic handles for surgical instruments

- Medical devices requiring permanent and biocompatible identification

- Handles with graduations, logos, or serial codes

- Marking type: laser engraving on medical-grade plastics

- Durability: resistant to sterilization, abrasion, and chemicals

- Surface protection: no structural damage or deformation

- Customization: text, logos, numbering, scales

- Compliance: ISO9001, ISO13485 medical device standards