Puncture Needle Wire Fixation and Sealing Welding

Puncture Needle Wire Fixation and Sealing Welding – precision laser sealing for needle wire joints

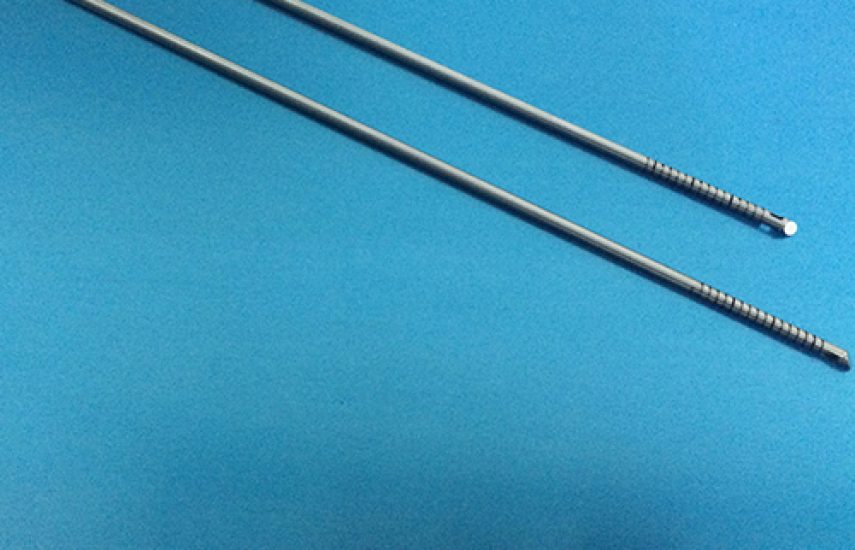

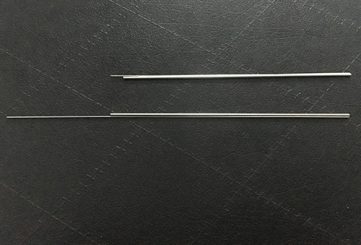

Puncture Needle Wire Fixation and Sealing Welding is a specialized laser welding process engineered to secure and hermetically seal wires within puncture needles. This method ensures stable fixation, smooth weld surfaces, and leak-proof integrity, critical for medical applications that demand accuracy, reliability, and biocompatibility. It delivers ultra-fine welds with minimal heat-affected zones, preserving material properties while guaranteeing consistent and repeatable performance.

Key features:

- Welding spot diameter: < Ø200 µm for ultra-fine and strong joints

- Hermetic sealing: ensures leak-proof welds with complete structural integrity

- Smooth finish: no deformation, bumps, or discoloration

- Pneumatic automatic control: stable clamping and alignment for process repeatability

- Material compatibility: stainless steel, nickel-titanium, platinum-iridium, tantalum, cobalt-base alloys, aluminum, copper

- Precision programming: 2D and 2.5D CAM workflow for consistent welding paths

Certification and Standards:

Manufactured in compliance with ISO9001 and ISO13485 certified quality systems; processes meet international medical device standards with traceability, biocompatibility, and laser safety for surgical and implantable components.

Copper (Cu):

A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

Aluminum alloy:

Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

Tantalum:

Tantalum is a highly corrosion-resistant, biocompatible metal with excellent strength and ductility. Ideal for precision laser welding, it ensures robust, smooth joints for critical medical components like implants and surgical instruments, offering superior radiopacity and durability.

Cobalt Base:

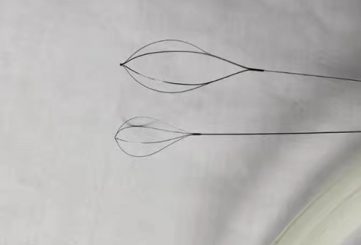

Cobalt Base alloys are highly durable, corrosion-resistant materials with excellent strength and biocompatibility. Perfect for precision laser welding, they provide robust, smooth welds for medical components like stone retrieval baskets.

Stainless Steel SUS304:

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

Platinum-Iridium:

Platinum-Iridium is a biocompatible, corrosion-resistant alloy with exceptional durability and conductivity. Ideal for precision laser welding, it ensures strong, smooth joints for critical medical components like stone basket heads.

Nickel-Titanium alloy:

Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

- Puncture needles requiring secure wire fixation and hermetic sealing

- Surgical instruments with wire-to-needle joints

- Medical devices and implants using fine-diameter wires and tubing

- Welding spot diameter: < 200 µm

- Sealing quality: leak-proof, smooth finish, no deformation or discoloration

- Clamping system: pneumatic automatic control

- Material compatibility: stainless steel, Ni-Ti, platinum-iridium, tantalum, cobalt-base alloys, aluminum, copper

- Software: 2D and 2.5D CAM for repeatable path programming