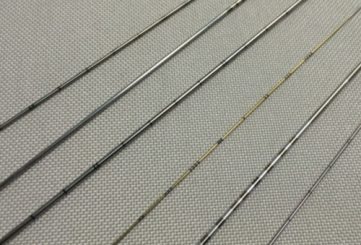

Surgical Instrument Join and Tube Body Welding

Surgical Instrument Join and Tube Body Welding – Precision Laser Welding for Medical Tools

Surgical Instrument Join and Tube Body Welding is a high-precision laser welding process tailored for assembling surgical instruments and medical tubing. Utilizing advanced fiber laser technology, this process delivers seamless, high-strength welds with minimal thermal distortion, ensuring robust and biocompatible connections. Ideal for creating reliable joints in complex medical devices, it supports intricate designs for surgical tools and tubing used in minimally invasive procedures, guaranteeing exceptional performance and durability.

Key Features:

- High Precision Welds: Achieves weld seam widths as low as 20μm for intricate, reliable joints.

- Minimal Thermal Impact: Fiber laser technology minimizes heat-affected zones, preserving material integrity.

- Robust Joints: Ensures strong, durable welds capable of withstanding mechanical stress in surgical applications.

- Biocompatible Materials: Compatible with medical-grade stainless steel, titanium, and nitinol for safe medical use.

- Customizable Weld Patterns: Allows tailored welding configurations for specific instrument and tubing designs.

- Smooth Weld Finish: Produces burr-free, polished welds, critical for safe and effective medical device performance.

Certification and Standards:

Compliant with ISO 13485 and relevant medical manufacturing standards, ensuring quality and safety for medical applications.

Cobalt Base:

Cobalt Base alloys are highly durable, corrosion-resistant materials with excellent strength and biocompatibility. Perfect for precision laser welding, they provide robust, smooth welds for medical components like stone retrieval baskets.

Stainless Steel SUS304:

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

Platinum-Iridium:

Platinum-Iridium is a biocompatible, corrosion-resistant alloy with exceptional durability and conductivity. Ideal for precision laser welding, it ensures strong, smooth joints for critical medical components like stone basket heads.

Nickel-Titanium alloy:

Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

Aluminum alloy:

Aluminum Alloys are lightweight, medical-grade materials valued for their excellent corrosion resistance and high strength-to-weight ratio. With tensile strength typically ranging from 200–600 MPa and good ductility, they offer durability for medical and industrial applications. Their biocompatibility supports use in non-implantable devices and components. Laser-machined for smooth, burr-free surfaces, they minimize contamination risks and ensure compatibility with sterilization processes.

Copper (Cu):

A conductive, antimicrobial metal used in medical equipment and coatings. Its excellent electrical conductivity and natural resistance to bacteria enhance device functionality and hygiene.

Tantalum:

Tantalum is a highly corrosion-resistant, biocompatible metal with excellent strength and ductility. Ideal for precision laser welding, it ensures robust, smooth joints for critical medical components like implants and surgical instruments, offering superior radiopacity and durability.

Surgical Instrument Join and Tube Body Welding is widely used in the production of surgical tools and medical tubing for urological, endoscopic, and other minimally invasive procedures. It enables the creation of reliable joints for instruments like forceps, scissors, and catheters, as well as robust tubing assemblies, ensuring biocompatibility and operational efficiency.

- Laser Type: Fiber laser for precision welding

- Weld Seam Width: As low as 20μm

- Welding Accuracy: ±5μm

- Supported Materials: Medical-grade stainless steel, titanium, nitinol

- Weld Depth: Up to 0.5 mm

- Automation: CNC-controlled with automated positioning systems

- Safety Features: Fully enclosed system for operator safety