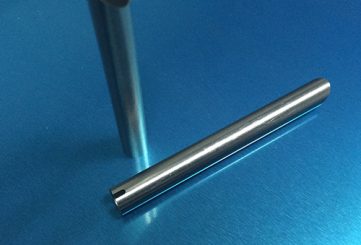

Heteromorphic Microtubule Openings

Heteromorphic Microtubule Openings – Precision Micro-Structures for Advanced Medical Applications

Heteromorphic Microtubule Openings are ultra-fine, high-precision microtubule structures designed for micro-catheter and endoscopic systems. Crafted from medical-grade SUS304 stainless steel, these microtubules feature custom-shaped openings for enhanced functionality in minimally invasive procedures. Produced using advanced laser micromachining, they ensure burr-free surfaces and precise geometries, enabling seamless integration into medical devices while maintaining corrosion resistance and biocompatibility.

Key Features:

- Ultra-High Precision: Achieves cutting seam widths of 15–30μm and accuracy of ≤±10μm for burr-free, custom-shaped openings.

- Customizable Openings: Tailored geometries enhance functionality for specific medical applications.

- Biocompatibility: Hypoallergenic material minimizes tissue reaction, ideal for direct contact in sensitive procedures.

- Superior Durability: Offers high tensile strength and corrosion resistance for reliable performance in physiological environments.

- Efficient Integration: Compatible with various clamping systems and cutting methods for rapid assembly.

- Sterility Maintenance: Smooth finish reduces contamination risks and supports sterilization processes.

Certification and Standards:

Heteromorphic Microtubule Openings comply with ISO 13485 quality management standards for medical devices and adhere to biocompatibility requirements under ISO 10993.

Stainless Steel SUS304:

Medical-grade SUS304 stainless steel (austenitic chromium-nickel alloy), offering excellent corrosion resistance and mechanical properties.

- Biocompatibility: Low risk of allergic reactions or toxicity, ideal for direct tissue contact in medical procedures.

- Mechanical Properties: High tensile strength (approximately 505 MPa) and elongation (up to 40%), providing flexibility without brittleness.

- Surface Finish: Laser-machined for smooth, burr-free edges, reducing the potential for tissue trauma or contamination.

- Thermal Stability: Maintains integrity across a wide temperature range, suitable for sterilization processes like autoclaving.

Nickel-Titanium alloy:

Nitinol (NiTi), a nickel-titanium alloy, is renowned for its superelasticity and shape memory, making it a game-changer in medical applications. With a tensile strength of up to 1200 MPa and elastic modulus of 40–75 GPa, nitinol excels in demanding environments.

Cobalt-chrome alloy:

Cobalt-chrome (CoCr), an alloy of cobalt and chromium often enhanced with molybdenum, is prized for its exceptional strength, corrosion resistance, and biocompatibility. With tensile strength ranging from 800–1500 MPa and hardness of 300–550 HV, CoCr is a cornerstone in medical technology. Popular grades like L605 (Co-Cr-W-Ni) and MP35N (Co-Cr-Ni-Mo) elevate its performance.

- Micro-Catheter Systems: Enhances functionality in vascular or urological procedures with custom-shaped microtubule openings.

- Endoscopy Systems: Supports precise fluid or tissue management in micro-endoscopes for minimally invasive interventions.

- Guidewire Integration: Integral to constructing advanced guidewire systems with high-precision requirements.

- Medical Device Repair: Employed in maintenance or replacement of microtubule components in catheter and endoscopic systems.

- Specialized Medical Designs: Adaptable for investigational or custom devices needing tailored flexibility in cardiology or neurology.

- Material Composition: SUS304 stainless steel.

- Dimensions: Customizable diameter, length, and opening geometries based on application requirements.

- Cutting Seam Width: 15–30μm.

- Machining Accuracy: ≤±10μm.

- Manufacturing Process: Advanced laser micromachining with continuous automatic feeding for burr-free, smooth finish.

- Clamping Compatibility: D-type collets, ER-series collets, three-jaw chucks.

- Cutting Methods: Dry or wet cutting options.

- Packaging: Sterilized and individually packaged to maintain integrity.

- Storage Conditions: Store in a dry, cool environment to prevent corrosion.