Nylon Tube Slotted & Slit

Nylon Tube Slotted & Slit – Precision Laser-Cut Tubing for Medical and Engineering

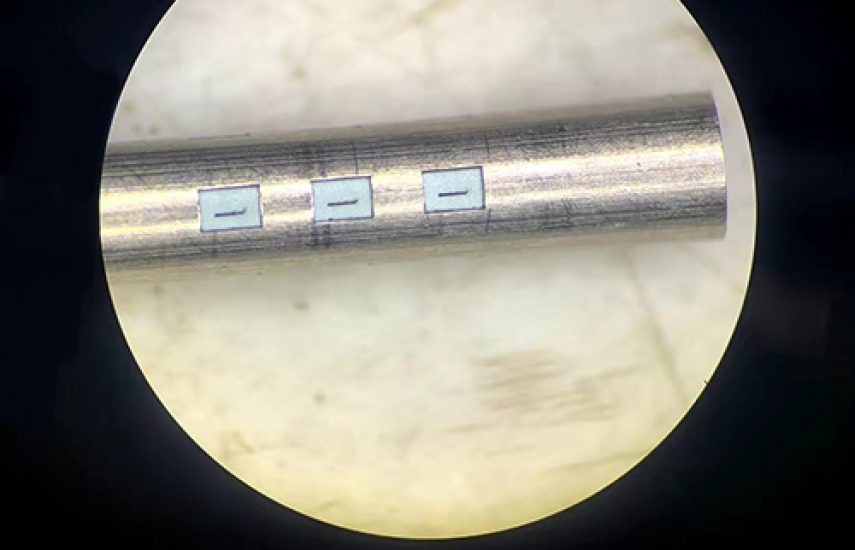

Nylon Tube Slotted & Slit is a high-precision component crafted using ultrafast femtosecond laser cutting technology. Designed for applications in the medical, pharmaceutical, and engineering industries, these nylon tubes feature precise slots or slits for fluid flow, structural support, or specialized mechanical functions. The laser micromachining process ensures smooth, burr-free cuts with minimal thermal impact, delivering exceptional performance and reliability. With high adaptability for both metallic and non-metallic materials, this product can be customized to meet specific application needs, ensuring functional and efficient performance.

Key Features:

- High Precision: Achieves cutting seam width of <20μm with machining accuracy of ±5μm for consistent, clean cuts.

- Minimal Thermal Impact: Femtosecond laser technology reduces heat-affected zones, preserving material integrity.

- Customizable Design: Slots and slits can be tailored to precise specifications for diverse medical and engineering applications.

- Burr-Free Edges: Ensures smooth surfaces, critical for fluid flow and biocompatibility in medical devices.

- Material Versatility: Compatible with various nylon grades, offering flexibility for specific performance requirements.

- High Durability: Nylon’s inherent strength and flexibility ensure long-lasting performance in demanding environments.

Certification and Standards:

Compliant with ISO 13485 and relevant medical manufacturing standards, ensuring quality and safety for medical applications.

Nylon (Polyamide):

Nylon (Polyamide) is a strong, flexible material with high wear resistance and chemical stability. Ideal for precision laser cutting, it delivers smooth edges and intricate designs for medical and engineering components.

Nylon Tube Slotted & Slit is widely used in medical, pharmaceutical, and engineering applications requiring precision tubing. It is ideal for fluid delivery systems, catheter components, and structural supports in medical devices, as well as specialized mechanical functions in engineering. The contact-free laser process minimizes contamination risks, making it suitable for sterile medical environments.

- Laser Type: Ultrafast femtosecond laser for precision cutting

- Cutting Accuracy: ±5μm

- Cutting Seam Width: <20μm

- Maximum Tube Diameter: Up to 100 mm

- Maximum Tube Length: Up to 2 meters

- Material Thickness: 0.2 mm to 5 mm

- Supported Material: Nylon (various grades)

- Automation: CNC-controlled with automated loading/unloading options

- Safety Features: Fully enclosed system for operator safety