WT0.06mm-0.2mm Electroplated Furnace Stainless Steel Sheet Cutting & Scribing & Marking

WT0.06mm-0.2mm Electroplated Furnace Stainless Steel Sheet Cutting – Precision Process for Ultra-Thin Medical and Industrial Templates

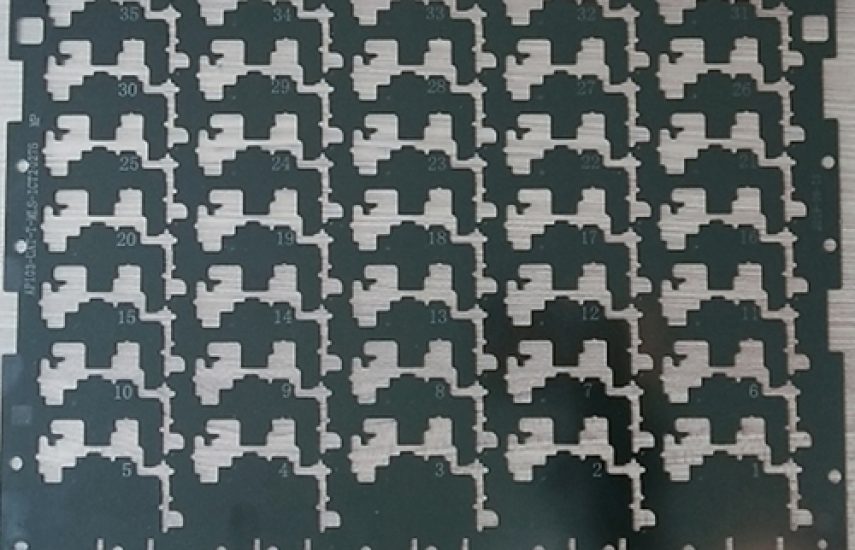

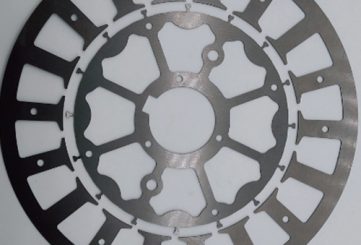

The WT0.06mm-0.2mm Electroplated Furnace Stainless Steel Sheet Cutting is a high-precision laser machining process designed to produce ultra-thin templates for medical and industrial applications. Utilizing advanced five-axis laser cutting, scribing, and marking technology, this process delivers exceptional accuracy, durability, and a burr-free finish. Crafted from high-quality electroplated stainless steel with thicknesses ranging from 0.06 mm to 0.2 mm, it offers superior corrosion resistance and strength, ideal for surgical tools, diagnostic devices, and precision industrial systems. The laser-cut design ensures smooth surfaces, intricate patterns, and precise markings, optimizing performance in demanding environments. Tailored for high-precision applications, this process meets the rigorous standards of modern healthcare and engineering.

Key Features:

- Ultra-Precise Cutting: Seam width of 15–30 µm with machining accuracy of ≤±10 µm for intricate template designs.

- Burr-Free Finish: Smooth surfaces ensure safe use and minimal tissue trauma in medical applications.

- Ultra-Thin Profile: Thickness range of 0.06–0.2 mm enables lightweight and precise templates.

- Electroplated Coating: Enhances corrosion resistance and surface durability for extended lifespan.

- High Strength: Stainless steel provides robust tensile strength for reliable performance.

- Automated Production: Continuous feeding system ensures high efficiency and consistent quality.

Certification and Standards:

Certified under ISO 9001 and ISO 13485 for quality management. Compliant with CE and FDA regulations for medical device safety and efficacy.

Electroplated Stainless Steel:

- Enhanced corrosion resistance through electroplating ensures durability in harsh environments.

- High tensile strength (500–1000 MPa) provides robust structural integrity.

- Biocompatibility (ISO 10993) makes it ideal for medical implants and tools.

- Smooth surface finish (Ra <0.2 µm) minimizes tissue trauma and enhances precision.

Precision Stainless Steel:

- Exceptional corrosion resistance ensures durability in harsh medical and industrial environments.

- High tensile strength (500–1000 MPa) provides robust structural integrity.

- Biocompatibility (ISO 10993) makes it ideal for medical implants and tools.

- Smooth surface finish (Ra <0.2 µm) minimizes tissue trauma and enhances performance.

Hard Alloy Steel:

- Superior hardness (up to 60–65 HRC) ensures excellent wear resistance.

- High strength and toughness support heavy-duty applications in surgical and industrial tools.

- Corrosion resistance extends lifespan in demanding environments.

- Precision machinability allows for intricate designs with tight tolerances.

Other Surface-Treated Materials:

- Includes coated or anodized metals like titanium, aluminum, and stainless steel with enhanced surface properties.

- Surface treatments such as passivation, nitriding, or PVD coatings improve wear resistance, biocompatibility, and corrosion protection.

- Medical Devices: Essential for ultra-thin components in surgical tools and diagnostic equipment.

- Industrial Systems: Used in precision templates for electronics and automation systems.

- Surgical Instruments: Supports intricate designs in minimally invasive surgical devices.

- Diagnostic Equipment: Incorporated in high-precision imaging and monitoring systems.

- Medical Device Manufacturing: Used in the production of advanced precision components.

- Material: Electroplated Stainless Steel (e.g., SUS304, SUS316L)

- Thickness: 0.06–0.2 mm

- Cutting Seam Width: 15–30 µm

- Machining Accuracy: ≤±10 µm

- Surface Roughness: Ra <0.2 µm

- Manufacturing Process: Five-axis laser cutting, scribing, and marking with automated feeding

- Operating Temperature: -20°C to 300°C, suitable for sterilization

- Degradation: Non-degradable, designed for long-term stability