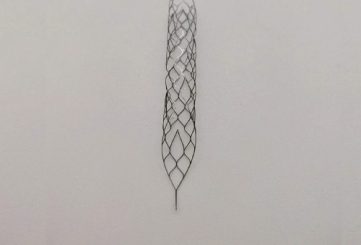

Valve stent NiTi & L605 D23mm WT0.5mm

Valve Stent NiTi & L605 D23mm WT0.5mm – advanced hybrid stent for large vessel support

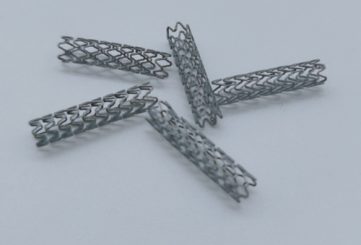

The Valve Stent NiTi & L605 D23mm WT0.5mm is a cutting-edge hybrid medical device meticulously engineered to provide robust and adaptable support within large vessels and complex anatomical structures, particularly for valvular applications. This innovative stent combines the unique properties of Nitinol (NiTi) and L605 Cobalt-Chromium alloy to deliver a synergistic performance. Its precisely constructed microstructure, featuring a 23mm diameter and 0.5mm wall thickness, ensures optimized radial force, exceptional fatigue resistance, and long-term durability, making it an ideal solution for advanced interventional procedures.

Key Features:

- Hybrid Material Composition: Integrates the superelasticity and shape memory of Nitinol with the superior radial strength and radiopacity of L605 Cobalt-Chromium.

- Optimal Dimensions: Large 23mm diameter and 0.5mm wall thickness designed for effective support in larger vessels and specific valvular anatomies.

- Engineered Microstructure: Provides high fatigue resistance and long-term durability within dynamic cardiovascular environments.

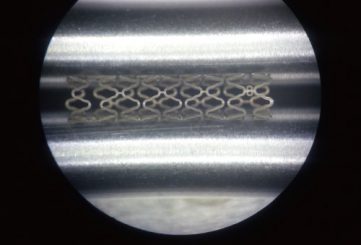

- Enhanced Radiopacity: Ensures clear visualization and precise placement under fluoroscopic guidance due to the L605 component.

- Biocompatible Surface: Promotes healthy endothelialization and significantly reduces thrombogenicity, crucial for long-term patient outcomes.

Certification and Standards:

Our Valve Stent NiTi & L605 D23mm WT0.5mm is manufactured under stringent quality control protocols, adhering to the highest international medical device standards, including ISO 13485:2016 and CE marking requirements. Each device undergoes comprehensive testing to guarantee its safety, performance, and efficacy in clinical applications.

NiTi (Nickel-Titanium Alloy)

NiTi, also known as Nitinol, is a shape memory alloy composed of roughly equal parts of nickel and titanium. Its unique properties include:

- Shape Memory Effect: The ability to return to a pre-defined shape when heated.

- Superelasticity: High elasticity, allowing the material to undergo significant deformation and recover without permanent damage.

- Corrosion Resistance: Excellent resistance to corrosion, particularly in biological and marine environments.

- Biocompatibility: Commonly used in medical applications such as stents, orthodontic wires, and surgical tools.

These properties make NiTi widely used in medical devices, aerospace, robotics, and industrial applications.

L605 (Cobalt-Chromium Alloy)

L605, also known as Haynes 25 or Alloy 25, is a cobalt-chromium-tungsten-nickel alloy recognized for its exceptional strength and resistance to high temperatures. Key characteristics include:

- High-Temperature Resistance: Excellent performance in environments up to 1093°C (2000°F).

- Wear and Corrosion Resistance: Outstanding resistance to oxidation, scaling, and various forms of corrosion.

- Biocompatibility: Suitable for use in medical implants, including heart valves and surgical components.

- Durability: High strength and resistance to mechanical fatigue.

L605 is commonly used in the aerospace industry, gas turbines, and medical applications due to its excellent mechanical and chemical properties.

The Valve Stent NiTi & L605 D23mm WT0.5mm is engineered for a broad range of advanced interventional procedures requiring substantial vessel or valve support. Its large diameter and robust construction make it particularly suitable for applications within the cardiovascular system, where sustained patency and structural integrity are paramount. Potential applications include, but are not limited to:

- Providing structural support in large peripheral arteries or veins.

- Use in specific transcatheter valve-in-valve or valve-in-ring procedures.

- Addressing challenging cases of vessel stenosis or pseudoaneurysm repair requiring high radial force.

- Stabilization of vessel walls post-dilation in complex anatomical regions.

- Supporting reconstructed segments in vascular surgery.

The stent's design ensures precise and controlled deployment, contributing to optimal patient outcomes in complex interventional scenarios.

- Stent Diameter: 23.0 mm (Self-expanding to nominal diameter)

- Wall Thickness (WT): 0.5 mm

- Material Composition: Hybrid Nitinol (NiTi) and L605 Cobalt-Chromium Alloy

- Available Lengths: Offered in a range of standard lengths to accommodate diverse anatomical requirements.

- Radial Force: Optimized to ensure stable apposition and robust lumen support without impeding cardiac or vascular flow dynamics.

- Fatigue Resistance: Engineered for exceptional long-term durability within dynamic cardiovascular environments.

- Sterilization Method: EO (Ethylene Oxide) Sterilized.

- Packaging: Individually sterile-packed to ensure integrity for single-use application.

- Compatibility: Fully compatible with conventional large-bore delivery systems and suitable for precise and controlled deployment.

- Radiopacity: Enhanced for superior visualization during fluoroscopic guidance, ensuring accurate placement.