Zinc Flakes

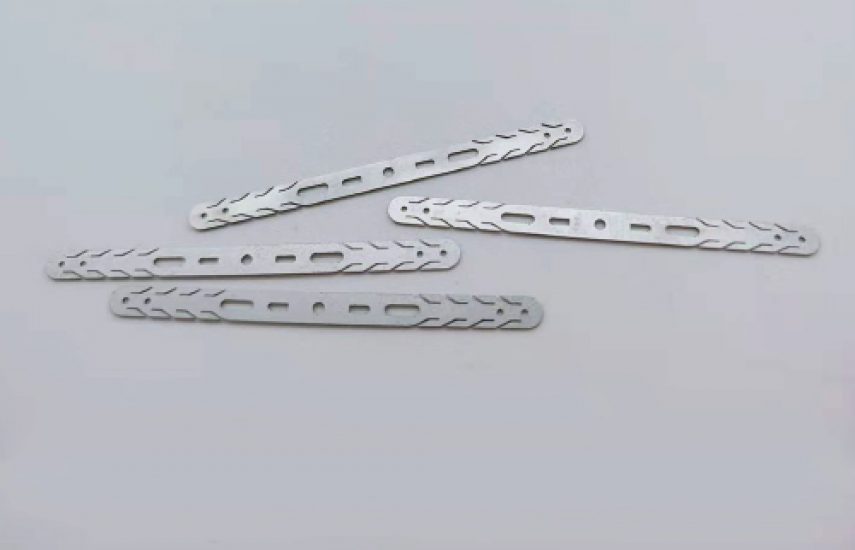

Zinc Flakes – Bioabsorbable Vascular Stents

Zinc Flakes are advanced bioabsorbable vascular stents designed to treat coronary and peripheral artery diseases. Crafted from high-purity zinc, these stents provide temporary mechanical support to arteries during the healing process, gradually corroding into non-toxic zinc compounds that are safely metabolized or excreted by the body. Unlike traditional metallic stents, Zinc Flakes eliminate the need for permanent implants, reducing long-term complications such as restenosis and thrombosis. Their eco-friendly design, derived from sustainable sources, aligns with the body’s natural processes, offering a safe and sustainable solution for cardiovascular interventions.

Key Features:

- Biodegradability: Fully corrodes into non-toxic zinc compounds, absorbed or excreted by the body over 18–24 months.

- High Biocompatibility: Minimizes inflammatory responses and supports natural tissue regeneration.

- Radial Strength: Provides sufficient mechanical support during vascular remodeling.

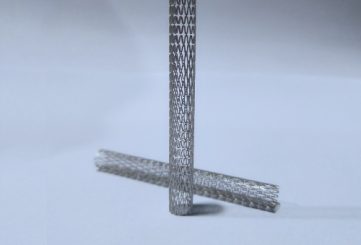

- Flexibility: Adapts to arterial curvature, reducing stress on vessel walls.

- Reduced Thrombosis Risk: Eliminates long-term foreign body presence, lowering the risk of late stent thrombosis.

- Tunable Properties: Molecular weight and crystallinity can be adjusted to optimize corrosion rate and mechanical strength.

- Eco-Friendly: Derived from sustainable sources, minimizing environmental impact during production and degradation.

- FDA-Approved: Meets rigorous safety and efficacy standards for medical applications.

Certification and Standards:

Zinc Flakes comply with ISO 10993-4 standards for hemocompatibility, ensuring minimal hemolysis and excellent anti-thrombotic properties. They are FDA-approved for use in cardiovascular applications and adhere to stringent biocompatibility and performance benchmarks. Manufacturing processes align with ISO 13485 quality management standards for medical devices, ensuring consistent quality and safety.

High-purity zinc (≥99.99% Zn), ensuring minimal impurities for optimal biocompatibility.

- Controlled Corrosion: Degrades into zinc oxide and zinc hydroxide, which are metabolized or excreted by the body, avoiding harmful byproducts like hydrogen gas.

- Mechanical Stability: Tensile strength of approximately 100–150 MPa, suitable for temporary vascular support, with ductility enhanced at physiological temperatures (37°C).

- Biocompatibility: Exhibits low cytotoxicity, promotes endothelialization, and reduces chronic inflammation compared to stainless steel or cobalt-chromium stents.

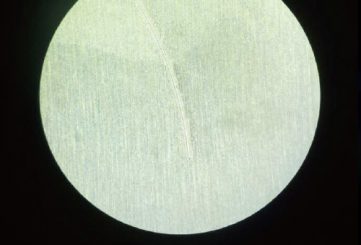

- Microstructural Refinement: Fine grain sizes (10–20 μm) achieved through advanced processing (e.g., extrusion, laser cutting), improving strength and corrosion behavior.

- Corrosion Rate: Optimized at ~0.02 mm/year in physiological conditions, aligning with tissue healing timelines.

- Coronary Artery Disease: Restores blood flow in blocked coronary arteries, supporting vessel walls during healing.

- Peripheral Artery Disease: Treats occlusions in peripheral vessels, maintaining patency.

- Pediatric Interventions: Suitable for children due to its degradable nature, avoiding complications from permanent implants.

- Arteriovenous Fistula (AVF) Maturation: Assists in dilating veins for hemodialysis access, degrading after maturation.

- Ureteral and Biliary Support: Potential use in non-vascular systems for temporary support in ureteral or biliary obstructions.

- Material Composition: High-purity zinc (≥99.99% Zn).

- Dimensions: Standard stent length: 20 mm; diameter: 3–6 mm (expandable via balloon); strut thickness: ~180 μm.

- Degradation Period: 18–24 months, fully metabolized or excreted.

- Tensile Strength: 100–150 MPa; yield strength: ~80–120 MPa.

- Manufacturing Process: Laser-cut from extruded high-purity zinc tubes, electropolished for smooth surface finish; compatible with 3D printing for patient-specific designs.

- Surface Treatment: Optional coatings (e.g., TiO2) to enhance corrosion resistance and endothelial cell adhesion.

- Packaging: Sterilized with ethylene oxide, individually sealed to maintain integrity.

- Storage Conditions: Store at room temperature, avoiding high humidity to prevent premature corrosion.